otc16089

Copyright 2004, Offshore Technology Conference

This paper was prepared for presentation at the Offshore Technology Conference held in Houston, Texas, U.S.A., 3–6 May 2004.

This paper was selected for presentation by an OTC Program Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the Offshore Technology Conference and are subject to correction by the author(s). The material, as presented, does not necessarily reflect any position of the Offshore Technology Conference or its officers. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the Offshore Technology Conference is prohibited. Permission to reproduce in print

is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of where and by whom the paper was presented.

Abstract

This paper summarizes the responsibilities between the Minerals Management Service (MMS), United States Coast Guard (USCG), the American Bureau of Shipping (ABS), and BP Exploration & Production, Inc. (BP) as the Operator for gaining regulatory approval on the new technology of synthetic (polyester) moorings. More specifically, the Mad Dog Project received the first approval for the permanent use of polyester moorings in the Gulf of Mexico.

Authors present the regulatory strategy and corresponding structure in regard to the Mad Dog Truss Spar Taut Leg Mooring System. This paper chronicles the Operator’s roadmap in engaging the MMS, USCG, and ABS upon making the decision to use polyester through obtaining the necessary regulatory concurrence.

Introduction

The offshore industry in the Gulf of Mexico (GoM) has expanded to water depths in the 10,000’ range. Technology has also expanded to take on the ever-increasing challenges presented in the harsher conditions, one such innovation being the use of synthetic moorings.

Polyester moorings have been successfully used on floating facilities in offshore Brazil in water depths over 4000 feet. Also, BP ran a test case on a Mobile Offshore Drilling Unit (MODU) to test handling, installation, and recovery procedures, as well as functionality testing and testing of recovered lines. While the latter was in the GoM, it was set as a temporary mooring configuration.

In order to gain approval for the permanent use of polyester mooring in the GoM, the regulations as set out by the MMS and USCG, as well as the delegations of responsibility resulting from the Memorandum Of Understanding (MOU)1, had to be satisfied or equivalencies established. ABS was also involved in the process, with their role being to satisfy Classing requirements and provide third party verification.

This concept was considered new and unusual for the GoM, although acknowledgement existed that the constituent parts of this concept were indeed proven technologies. However, since the common established mooring practice for floating facilities is steel rope and wire chain, it was necessary for BP as the Operator to demonstrate that polyester provides an equivalent or better level of operability. This paper summarizes the methods and strategies used in positively engaging the regulatory agencies with this new technology and eventually gaining the necessary consensus approvals, all within a relatively short time period and with a tight project schedule.

Mad Dog Truss Spar and Mooring Configuration The Mad Dog Truss Spar is located approximately 190 miles south of New Orleans, Louisiana in Green Canyon (GC) Block 782. The nominal water depth is 4500’ and the field runs along the Sigsbee Escarpment (where the bottom is 6500’). The local regulatory offices are the MMS Houma District as part of the MMS GoM Region and the USCG Morgan City Marine Safety Office as part of the USCG Eighth District.

The hull is 128’ in diameter, 555’ long, and has an 11-line taut mooring configuration. There are three mooring line groups – two with four lines and one with three lines. Technical paper OTC 16589 details this further2.

Regulatory and Classification Organizations Regulatory Agencies and Corresponding Regulations. The MMS and the USCG had integral approval responsibilities of this process. Their respective main regulations are referenced3,4,5. Through the MOU, both agencies share responsibilities of the mooring system. Polyester moorings are not specifically addressed as such therefore, two recommended practices by the American Petroleum Institute (API) became very important.

API Recommended Practice (RP) 2-SM for synthetic

moorings and 2-SK for station keeping discuss guidelines for

OTC 16089

Mad Dog Project: Regulatory Approval Process for the New Technology of Synthetic (Polyester) Moorings in the Gulf of Mexico

D.L. Bugg, BP Exploration & Production, Inc.; D.T. Vickers, BP Exploration & Production, Inc.; and C.J. Dorchak, Jr., American Bureau of Shipping

2 . OTC

16089

synthetic mooring design, fabrication, and installation as well as station keeping abilities as applicable to any set of moorings6,7.

Classification. Classification generally covers design, fabrication, and installation as well as inspection, maintenance, repair, and retirement (IMRR) planning. ABS has Rules, Guides, and Standards that have been developed over the years for this and other purposes8,9,10. This also includes ABS Guide for Synthetic Ropes in Offshore Mooring Applications 11. The Mad Dog Truss Spar will be classed as

?A1 Floating Offshore Installation (FOI)upon completion of the appropriate reviews. Classification is not a requirement but is considered an excellent assurance tool.

MMS. Located within the Department of the Interior, the MMS acts as the steward of the federal waters of the Outer Continental Shelf (OCS) and is responsible for balancing the Nation’s search for energy and marine minerals with the protection of the human, marine and coastal environment. The MMS is the primary agency for managing oil and gas production in the GOM. The role of MMS is conservation of natural resources and economic return, protection of the environment, and safe operations. Functions lie within Region and District levels.

USCG. Located within the newly formed Department of Homeland Security, the USCG’s five primary operating goals are: Safety, Protection of Natural Resources, Mobility, Maritime Security and National Defense. The USCG is the primary agency for assurance of vessel seaworthiness, personnel protection on floating vessels, and oil spill response. ABS. The ABS is a vessel classification society that acts as an agent for the USCG for specific items under a unique regulatory arrangement with the USCG. ABS also performs Certified Verification Agent (CVA) duties.

Responsible Offices. The responsibility for this review fell specifically on two entities:

? the Office of Structural and Technical Support of the MMS GoM Region in New Orleans, Louisiana and ? the Structures and Stability Branch of the USCG Marine Safety Center in Washington, D.C.

The involvement of ABS served as a Third-Party verification of the planning as well as fulfilling class requirements. This primarily came from their Engineering Group in Houston, Texas.

Other groups within these organizations contributed / assisted as well.

Regulatory Roadmap for Mad Dog

Considerations / Questions. While many things were taken into consideration during the process of deciding to pursue polyester moorings for the Mad Dog Project, following are some of the key considerations from the regulatory perspective:

? Are there safety and/or environmental issues

(positive and negative)?

? If negative, what are the mitigating factors?

? Is polyester or other synthetic moorings being used elsewhere?

? If yes, where, how long, and in what type(s) of

application(s)?

? Are there design guidelines?

? What are the benefits to the project?

? Conversely, what are the potential consequences with and/or without use?

Overall, will a polyester taut-leg mooring system be an equivalent or better system than a traditional steel-wire chain system for this application?

Process. Once the project team felt the technical decisions were sound, the options had been weighed, and the decision made12, the regulatory strategy was laid out and executed. Table 1 is a chronology that tracks the time from the BP’s decision until final approvals. The following twelve items summarize the process:

? Development of a Regulatory Engagement Plan

? Early notification to the regulatory agencies

? Early engagement of the verification agent / technical authorities

? Establishing points-of-contact

? Basic information sharing and education on the

concept

? Initial submittals

? Periodic communication to gain clarity and promote cooperation

? Continued cooperative negotiation and revisions

? Approvals in principle

? Agreement on finalized terms

? Final submittals and approvals

? Post-approval communications

Development of a Regulatory Engagement Plan. Once the project team had decided to seek the use polyester moorings and asked BP Regulatory for advice, some time was taken initially to think through the entire process and construct a strategy. This strategy involved:

? Early identification of agencies involved and the individual groups within

? Resource identification

? Project timeline and requirements in relation to contractor negotiations and overall schedule ? Making agencies true partners in understanding the project and polyester moorings systems

Early notification to the regulatory agencies. Simultaneously, the identified agency groups were informed of our intentions

OTC 16089 3

and our desire to meet with them to begin formalizing the process. BP did was not want to give the perception that a rushed decision was expected on such a major topic, but also wanted to be open about the project scheduling. Subsequently, face-to-face meetings ensued.

Early engagement of the verification agent / technical authorities. In conjunction to contacting the regulators, the third-party verification agent was notified and invited to all meetings. Through their external work and validation, this helped strengthen the Operator’s position and fulfill various regulatory third-party requirements.

Furthermore, contract engineering technical services were employed to supplement internal technical authorities.

Establishing points-of-contact. To provide efficiency and clarification, points-of-contact were established between the various organizations.

Basic information sharing and education on the concept / Initial submittals. Deployment plans, past history of existing polyester lines, and technical information of polyester mooring lines (as well as traditional lines) were shared with the regulators to further enhance the knowledge base. The intent was to give a technical and practical case for polyester in general – leading to the Mad Dog Project in particular. During the initial meetings, submittal protocol and expectations were set. The first submittals were:

? New Technology Portion of the Preliminary

Deepwater Operations Plan – submitted to the MMS

Technical Assessment and Operations Support

Section, working in conjunction with the Office of

Structural and Technical Support (also, a copy was

sent to the MMS Houma District).

? Proposal to Use Polyester Moorings – submitted to the USCG Structures and Stability Branch, working

in conjunction with the Vessel and Facility,

Operating and Environmental Standards Division

(also, a copy was sent to the Marine Safety Division

of the Eighth Coast Guard District).

Periodic communication to gain clarity and promote cooperation. BP was contacted as each agency made their respective initial reviews. The USCG and MMS worked in concert during this process, raising questions and requesting clarifications in related timeframes and in a manner that answered questions all respective queries.

During this time, BP also submitted two documents that became very important pieces in the road to approval, those being:

? Inspection, Maintenance, Repair, and Retirement (IMRR) Plan

? Quality Assurance (Rope Manufacture and Splicing) Plan

These documents were also submitted to ABS.

Continued cooperative negotiation and revisions. While both agencies saw the importance in each document, the MMS focused on the IMRR and the USCG on the QA. The main point for the MMS was the conditions that would warrant a shut-in. There also was a desire to reduce / eliminate any unclear conditions and replace with clear situations with predetermined outcomes.

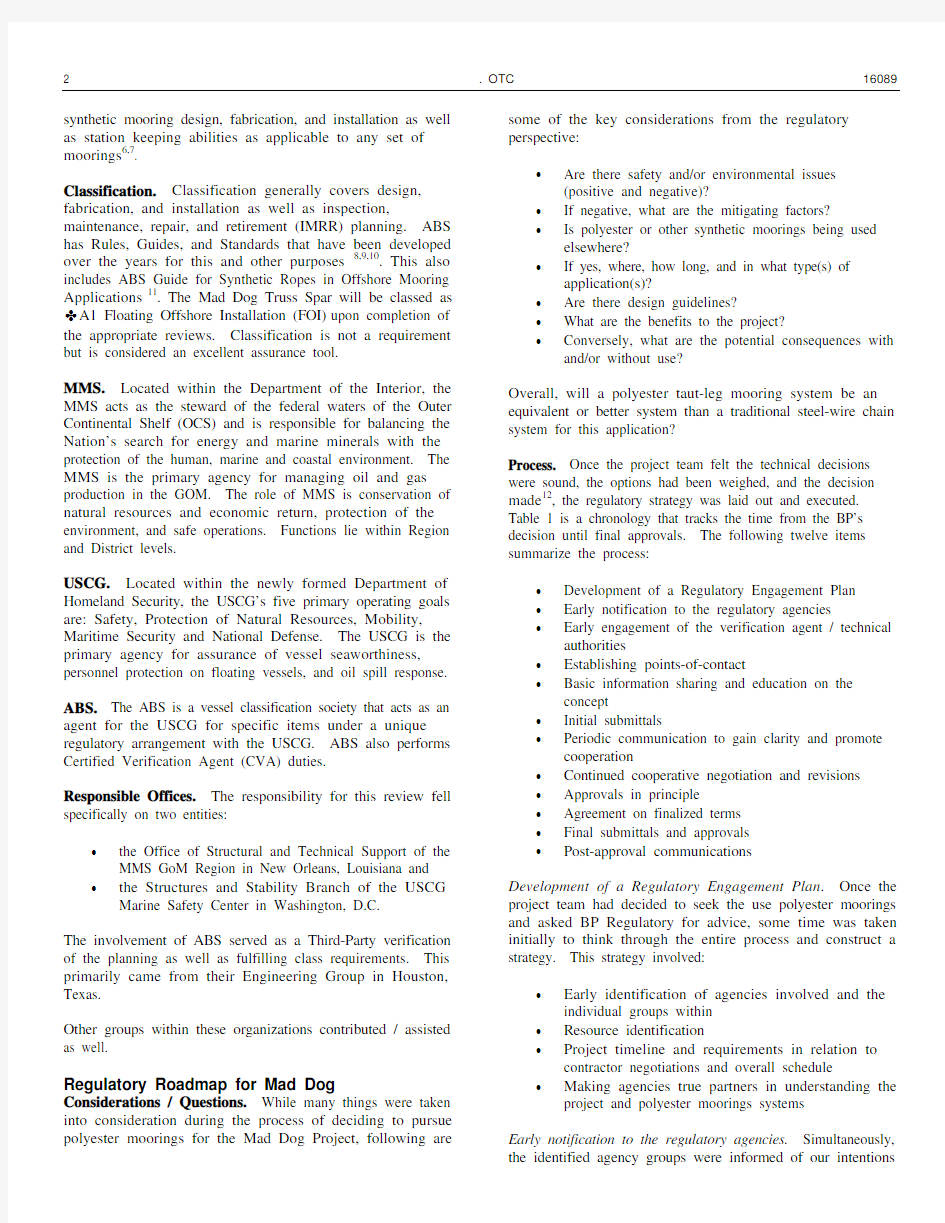

The main point for the USCG was assurance in the quality of the rope manufacturing, especially the splicing. The splice operation is done by hand and therefore introduces a potential greater chance for human error. Figure 1 shows a picture of a section of polyester rope being machine-assembled. Approvals in principle. Upon the agencies receiving a comfort level in the basic tenets of the proposal and the supporting information, approvals in principle were given. This basically served as an indication to continue our project planning with polyester as the base case, but also with the acknowledgement that there were clearly specified items that needed to be addressed. This also enabled the project team to continue the selection process of finding a rope vendor. Agreement on finalized terms / Final submittal and approvals. This marked a period of revision submittals and subsequent conversations, whether via telephone or face-to-face (or a combination). Amongst many items, clear decisions in the IMRR were agreed upon for conditions of shut-in and in the QA plan for acceptability criteria.

It proved very beneficial to have a final conversation with the agencies and go through a checklist of the specific items and the solutions / answers to address. After the compilation of the last considerations, the final plans were submitted and subsequently approved.

Post-approval communications. The approval process was a cooperative effort complete with open dialogue. Therefore, post-approval communications transpired which included updates of rope manufacturing, overall project updates, installation timelines, and other items of interest as related to the mooring system. This is an evergreen process. Conclusion

The approval and implementation of the Mad Dog Taut-Leg Polyester Mooring System exhibited the true spirit of cooperation and dedication / commitment to the advancement of the offshore industry and domestic energy production.

A thorough regulatory plan is necessary with all contacts identified. Early examination of the agencies’ major concerns and focus on gaining information to answer those concerns was critical. By involving the MMS and USCG early, there was consistency and clarity for the final approvals.

16089 4 . OTC

By involving ABS and other technical authorities early, the

project teams were able to avoid potential discrepancies with

regulatory requirements thus saving review times.

Undoubtedly, this has opened the doors to other GoM

applications and will further the industry by continuing to

extend the applications of technology development to the

ultra-deepwater.

Acknowledgements

The authors thank the Mad Dog Project Team, especially the

Mad Dog Floating Systems Team for their diligence in pulling

the information together for the various submittals and their

collaboration during this process. We also thank the several

persons at the MMS (especially the Offices of Structural and

Technical Support and the Technical Assessment and

Operations Support Section) and the USCG (especially the

Tank Vessel and Offshore Division, Structures and Stability

Branch) who worked with us to successfully gain approvals

for the first permanent use of synthetic (polyester) moorings in

the Gulf of Mexico.

References

1. Memorandum of Understanding between Mineral Management

Service and the United States Coast Guard Concerning

Regulation of Activities on the Outer Continental Shelf of the

United States, December 16, 1998

2. OTC 16589, "Mad Dog Polyester Mooring - Prototype Testing

and Stiffness Model for Use in Global Performance Analyses",

by D.J. Petruska, J.F. Geyer and A.Z. Ran.

3. MMS: Code of Federal Regulations – Mineral Resources, Title

30 Part 250 - 2001

4. USCG: Code of Federal Regulations – Navigation and

Navigable Waters, Title 33 - 2001

5. USCG: Code of Federal Regulations – Shipping, Title 46 - 2001

6. American Petroleum Institute Recommend Practice 2-SM –

Synthetic Moorings, 2001

7. American Petroleum Institute Recommended Practice 2-SK –

Station Keeping, 1996

8. ABS Guide for Building and Classing Mobile Offshore Drilling

Units, 2001

9. ABS Guide for Building and Classing Floating Production

Installations, 2000

10. ABS Guide for Building and Classing Facilities on Offshore

Installations, 2000

11. ABS Guide for Synthetic Ropes in Offshore Mooring

Applications, 1999

12. OTC 16589, "Mad Dog Polyester Mooring - Prototype Testing

and Stiffness Model for Use in Global Performance Analyses",

by D.J. Petruska, J.F. Geyer and A.Z. Ran.

OTC 16089 5

Table 1: Mad Dog Polyester Mooring Approval Chronology

Date Event

12/15/2001 Internal conversation ensued about the use of polyester mooring to help gain topsides payload.

BP Regulatory to approach MMS.

1/10/2002 MMS Structural Section Chief approached during an industry meeting about the idea. He said he

was going to be in Houston and encouraged our moorings group to brief him.

2/4/2002 Briefing was held – a larger meeting was recommended and set up for 3/7/2002.

3/4/2002 USCG was invited to meeting and accepted invitation.

3/7/2002 Meeting in New Orleans between MMS/USCG and BP occurred -

? Both agencies did not want to be rushed into a decision.

? It was said that this would be a “one-off” and if viewed as a “policy” decision, approval

time could be over a year and into the years.

? The spirit of cooperation was invoked by all parties (MMS, USCG, ABS, and BP).

3/14/2002 BP Polyester Readiness Plan was submitted to MMS/USCG

3/21/2002 The New Technology Portion on the Preliminary Deepwater Operations Plan / Proposal to Use

Polyester Moorings was submitted to MMS / USCG

3/26/2002 Received call from USCG – Washington D.C, requesting a further review meeting (set for

4/5/2002). Also received call from MMS Technical Assessment group verifying receipt of our

package.

3/27/2002 BP Regulatory invites MMS from New Orleans and from Washington, D.C. technical headquarters

to 4/5/2002 meeting – invitation accepted.

4/5/2002 Meeting in Washington, D.C. between USCG/MMS and BP occurred –

? USCG stressed that they would take the time needed while remaining cognizant of our

schedule.

? MMS concurred

? ABS involvement continued

5/13/2002 Rev 0 versions of the Mad Dog IMRR and QA plans submitted to MMS / USCG and ABS.

6/13/2002 Rev 1 version of the Mad Dog IMRR Plan submitted to MMS / USCG and ABS.

6/20/2002 USCG letter was received, stated polyester moorings “acceptable in principle” with some pending

plan questions.

8/8/2002 Meeting at MMS occurred with Regional Director in attendance. He stated that all submittals

should continue to fit into “regulatory framework”.

8/8/2002 In a post-meeting discussion with the MMS Structural Section Chief, verbal endorsement was

given to continue with polyester moorings as base case.

9/5/2002 Teleconference occurred with MMS / USCG in reviewing the IMRR / QA Plans.

9/6/2002 Rev 2 version of the Mad Dog IMRR Plan submitted to MMS / USCG and ABS.

10/23/2002 Rev 1 version of the Mad Dog QA plan submitted to MMS / USCG and ABS.

11/15/2002 Teleconference with MMS / USCG in reviewing the IMRR / QA Plans.

11/19/2002 Rev 3 version of the Mad Dog IMRR Plan submitted to MMS / USCG and ABS.

11/19/2002 MMS approval of IMRR Plan granted.

1/27/2003 USCG verifies and amplifies “approval in principle” and states IMRR and QA plans “Examined”.

16089 6 . OTC

Figure 1: Mad Dog Polyester Mooring Picture during Manufacturing

10-5/8” diameter rope section being assembled