High-efficiency solar cells based on Cu(InAl)Se2 thin films

High-ef?ciency solar cells based on Cu…InAl…Se2thin?lms S.Marsillac,a)P.D.Paulson,M.W.Haimbodi,R.W.Birkmire,and W.N.Shafarman b)

Institute of Energy Conversion,University of Delaware,Newark,Delaware19716

?Received28May2002;accepted for publication17June2002?

A Cu(InAl)Se2solar cell with16.9%ef?ciency is demonstrated using a Cu(InAl)Se2thin?lm

deposited by four-source elemental evaporation and a device structure of glass/ Mo/Cu(InAl)Se2/CdS/ZnO/indium tin oxide/?Ni/Algrid?/MgF2.A key to high ef?ciency is improved adhesion between the Cu(InAl)Se2and the Mo back contact layer,provided by a 5-nm-thick Ga interlayer,which enabled the Cu(InAl)Se2to be deposited at a530°C substrate temperature.Film and device properties are compared to Cu(InGa)Se2with the same band gap of

1.16eV.The solar cells have similar behavior,with performance limited by recombination through

trap states in the space charge region in the Cu(InAl)Se2or Cu(InGa)Se2layer.?2002American Institute of Physics.?DOI:10.1063/1.1499990?

The Cu(InGa)Se2thin?lms in high ef?ciency solar cells

typically have Ga/(In?Ga)?0.1–0.3giving a band gap

(E g)?1.1–1.2eV.Signi?cant effort has been made to de-

velop high ef?ciency solar cells based on wider band gap

CuInSe2alloys by replacing In with Ga,or Se with S.The

goal is improved module performance resulting from the

tradeoff between higher voltage and lower current at maxi-

mum power which can allow fewer scribes for monolithic

integration or reduced losses in the transparent conducting

oxide layer.Further,wider band gaps could be used to de-

velop multijunction devices with even higher ef?ciency.

However,with band gaps greater than1.3eV,the ef?ciency

of Cu(InGa)Se2devices is limited by a degradation of the

electronic properties of the Cu(InGa)Se2layer leading to

losses in?ll factor?FF?and open circuit voltage(V OC).1,2

We have recently reported on Cu(InAl)Se2?lms depos-

ited by multisource elemental evaporation,in which the band

gap can be varied from1.0to2.7eV.3,4Solar cells with11%

ef?ciency were fabricated,but poor adhesion limited the sub-

strate temperature(T SS)used for the growth of the

Cu(InAl)Se2?lm which restricted the cell ef?ciency.In this

letter,a method to improve the adhesion,allowing higher

T SS,is presented and a Cu(InAl)Se2based solar cell with

16.9%ef?ciency is demonstrated.Film and device properties

are compared to Cu(InGa)Se2with the same band gap of

1.16eV.

Cu(InAl)Se2and Cu(InGa)Se2?lms were deposited by

elemental evaporation on Mo-coated soda lime glass at T SS ?530and550°C,respectively.The?lms were2.0–2.5?m thick.The ratio of Al or Ga to In was adjusted so that the

?lms had the same band gap.Delivery rates of all metals

were constant during the60min?lm growth and secondary

ion mass spectroscopy?SIMS?depth pro?le measurements

con?rmed that the?lms have uniform composition and,

therefore,band gap.At substrate temperatures greater than

450°C,the Cu(InAl)Se2did not adhere well to the glass/Mo substrate.It has been previously shown that the addition of

Ga to CuInSe2?lms improves their adhesion to Mo.5There-

fore,a5-nm-thick Ga?lm was sputtered onto the Mo prior

to the growth of Cu(InAl)Se2.This resulted in improved

adhesion and allowed?lms to be deposited at T SS?530°C. SIMS measurements showed that the Ga is distributed

through the Cu(InAl)Se2?lm,but it accounts for only0.3

at.%of the Cu(InAl)Se2.All Cu(InGa)Se2?lms exhibited

good adhesion.

The compositions of Cu(InAl)Se2and Cu(InGa)Se2

?lms were determined by energy dispersive x-ray spectros-

copy?EDS?and are shown in Table I.The ratios x?Al/(In ?Al)and Ga/(In?Ga)were0.13and0.26,respectively,for ?lms with E g?1.16eV.For the Cu(InAl)Se2,the optical absorption coef?cient???was determined by spectroscopic ellipsometry4and E g was obtained from the intercept of (?E)2plotted versus E.The band gap for Cu(InGa)Se2was determined from the composition as in previous work.1Scan-ning electron microscopy characterization of the surface and the cross section of the?lms shows similar surface morphol-ogy with columnar grains for both?lms,and cross-sectional grain width in the range of?1?m.

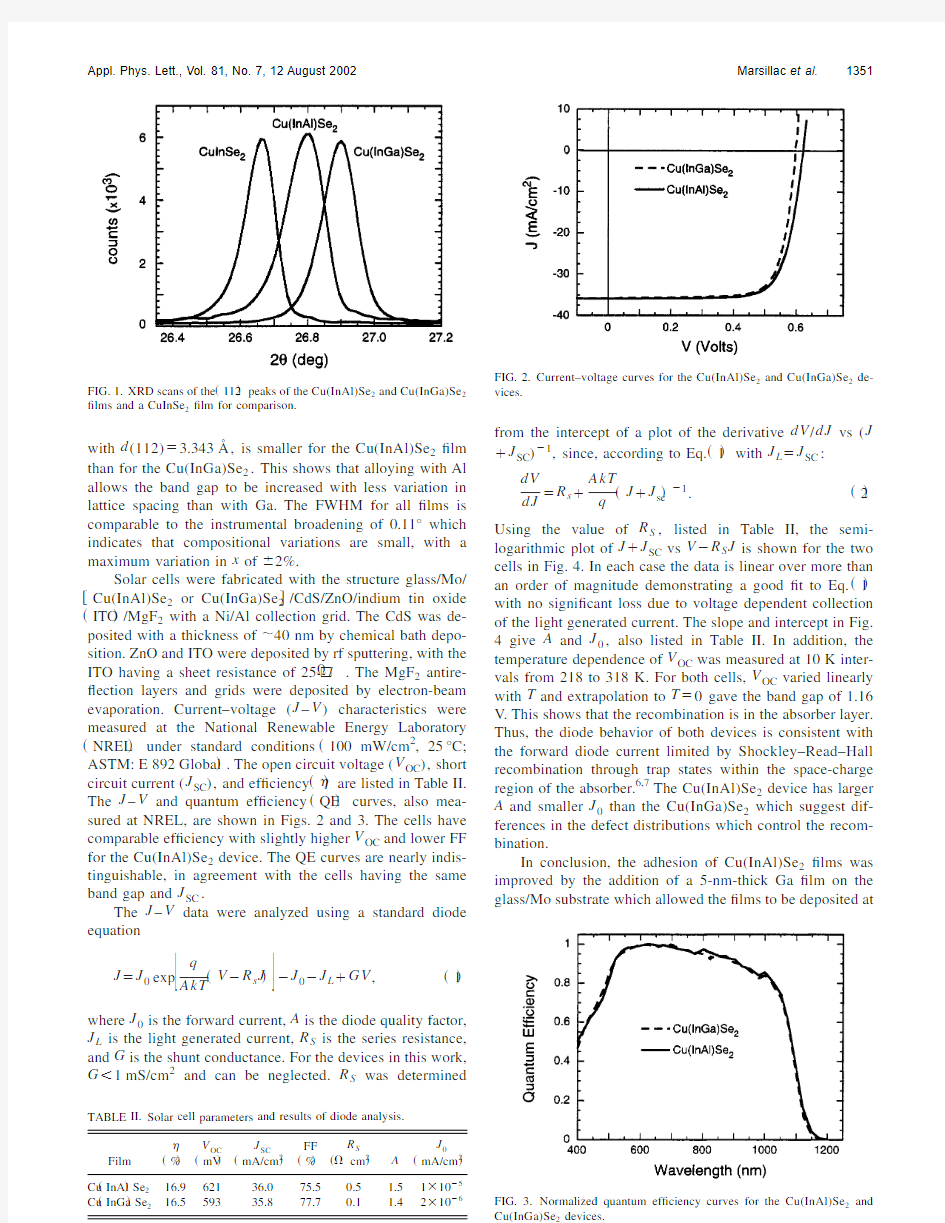

X-ray diffraction?XRD?measurements with Bragg–

Brentano??–2?con?guration?focusing geometry and Cu K?radiation show that the Cu(InAl)Se2and Cu(InGa)Se2?lms are single phase and nearly randomly oriented.Figure1 compares the?112?re?ections for CuInSe2,Cu(InAl)Se2, and Cu(InGa)Se2.The lattice spacing d(112)and full width at half maximum?FWHM?are included in Table I.In each case,the variation in lattice spacing with Al and Ga content follows Vegards law,4but the shift in d(112)from CuInSe2,

a?Permanent address:Equipe de Physique des Solides pour l’Electronique, FSTN,BP92208,2Rue de la Houssinie`re,44322Nantes Cedex03, France.

b?Electronic mail:wns@https://www.wendangku.net/doc/206183098.html, TABLE I.Results of EDS and XRD measurements on Cu?InAl?Se2and Cu?InGa?Se2?lms.

Sample Cu In

Al or

Ga Se x

d(112)

???

FWHM

?°?Cu?InAl?Se223.523.0 3.550.00.13 3.3240.14 Cu?InGa?Se224.119.7 6.949.30.26 3.3120.13

APPLIED PHYSICS LETTERS VOLUME81,NUMBER712AUGUST2002

1350

0003-6951/2002/81(7)/1350/3/$19.00?2002American Institute of Physics Downloaded 03 Jun 2010 to 121.15.171.100. Redistribution subject to AIP license or copyright; see https://www.wendangku.net/doc/206183098.html,/apl/copyright.jsp

with d (112)?3.343?,is smaller for the Cu(InAl)Se 2?lm than for the Cu(InGa)Se 2.This shows that alloying with Al allows the band gap to be increased with less variation in lattice spacing than with Ga.The FWHM for all ?lms is comparable to the instrumental broadening of 0.11°which indicates that compositional variations are small,with a maximum variation in x of ?2%.

Solar cells were fabricated with the structure glass/Mo/?Cu(InAl)Se 2or Cu(InGa)Se 2?/CdS/ZnO/indium tin oxide ?ITO ?/MgF 2with a Ni/Al collection grid.The CdS was de-posited with a thickness of ?40nm by chemical bath depo-sition.ZnO and ITO were deposited by rf sputtering,with the ITO having a sheet resistance of 25?/?.The MgF 2antire-?ection layers and grids were deposited by electron-beam evaporation.Current–voltage (J –V )characteristics were measured at the National Renewable Energy Laboratory ?NREL ?under standard conditions ?100mW/cm 2,25°C;ASTM:E 892Global ?.The open circuit voltage (V OC ),short circuit current (J SC ),and ef?ciency ???are listed in Table II.The J –V and quantum ef?ciency ?QE ?curves,also mea-sured at NREL,are shown in Figs.2and 3.The cells have comparable ef?ciency with slightly higher V OC and lower FF for the Cu(InAl)Se 2device.The QE curves are nearly indis-tinguishable,in agreement with the cells having the same band gap and J SC .

The J –V data were analyzed using a standard diode equation

J ?J 0exp

q

AkT

?V ?R s J ?

?J 0?J L ?GV ,?1?

where J 0is the forward current,A is the diode quality factor,J L is the light generated current,R S is the series resistance,and G is the shunt conductance.For the devices in this work,G ?1mS/cm 2and can be neglected.R S was determined

from the intercept of a plot of the derivative dV /dJ vs (J ?J SC )?1,since,according to Eq.?1?with J L ?J SC :

dV dJ ?R s ?AkT q

?J ?J sc ??1.?2?

Using the value of R S ,listed in Table II,the semi-logarithmic plot of J ?J SC vs V ?R S J is shown for the two cells in Fig.4.In each case the data is linear over more than an order of magnitude demonstrating a good ?t to Eq.?1?with no signi?cant loss due to voltage dependent collection of the light generated current.The slope and intercept in Fig.4give A and J 0,also listed in Table II.In addition,the temperature dependence of V OC was measured at 10K inter-vals from 218to 318K.For both cells,V OC varied linearly with T and extrapolation to T ?0gave the band gap of 1.16V .This shows that the recombination is in the absorber layer.Thus,the diode behavior of both devices is consistent with the forward diode current limited by Shockley–Read–Hall recombination through trap states within the space-charge region of the absorber.6,7The Cu(InAl)Se 2device has larger A and smaller J 0than the Cu(InGa)Se 2which suggest dif-ferences in the defect distributions which control the recom-bination.

In conclusion,the adhesion of Cu(InAl)Se 2?lms was improved by the addition of a 5-nm-thick Ga ?lm on the glass/Mo substrate which allowed the ?lms to be deposited

at

FIG.1.XRD scans of the ?112?peaks of the Cu(InAl)Se 2and Cu(InGa)Se 2?lms and a CuInSe 2?lm for

comparison.

FIG.2.Current–voltage curves for the Cu(InAl)Se 2and Cu(InGa)Se 2de-

vices.

FIG.3.Normalized quantum ef?ciency curves for the Cu(InAl)Se 2and Cu(InGa)Se 2devices.

TABLE II.Solar cell parameters and results of diode analysis.

Film ?

?%?V OC ?mV ?J SC ?mA/cm 2?FF ?%?R S ??cm 2?A J 0

?mA/cm 2?Cu ?InAl ?Se 216.962136.075.50.5 1.51?10?5Cu ?InGa ?Se 2

16.5

593

35.8

77.7

0.1

1.4

2?10?6

Downloaded 03 Jun 2010 to 121.15.171.100. Redistribution subject to AIP license or copyright; see https://www.wendangku.net/doc/206183098.html,/apl/copyright.jsp

a substrate temperature of 530°C.The higher substrate tem-perature resulted in Cu(InAl)Se 2with improved electronic properties and a solar cell with 16.9%ef?ciency was fabri-cated.The Cu(InAl)Se 2solar cells diode characteristics are similar to Cu(InGa)Se 2with the same band gap,limited by recombination through defect states in the absorber layer.

The authors thank https://www.wendangku.net/doc/206183098.html,mpros,K.Hart,T.Minemoto,and S.Hegedus at IEC for technical assistance,and C.Per-kins,S.Asher,and T.Moriarty at NREL for ?lm and device measurements.This work was supported,in part,by NREL under Subcontract No.ADJ-1-30630-12and by NIST under an Advanced Technology Program in collaboration with ITN Energy Systems and Global Solar Energy.

1

W.N.Shafarman,R.Klenk,and B.E.McCandless,J.Appl.Phys.79,7324?1996?.2

U.Rau,M.Schmidt,A.Jasenek,G.Hanna,and H.W.Schock,Sol.En-ergy Mater.Sol.Cells 67,137?2001?.3

M.W.Haimbodi,E.Gourmelon,P.D.Paulson,R.W.Birkmire,and W.N.Shafarman,Proc.28th IEEE Photovoltaic Specialists Conference,Anchor-age,AL ?IEEE,New York,2001?,p.454.4

P.D.Paulson,M.W.Haimbodi,S.Marsillac,W.N.Shafarman,and R.W.Birkmire,J.Appl.Phys.91,10153?2002?.5

C.Jensen,

D.Tarrant,J.Ermer,and G.Pollock,Proc.23rd IEEE Photo-voltaic Specialists Conference,Louisville,KY ?IEEE,New York,1993?,p.577.6

M.Roy,S.Damaskinos,and J.E.Phillips,Proc.20th IEEE Photovoltaic Specialists Conference,Las Vegas,NV ?IEEE,New York,1988?,p.1618.7

U.Rau and H.Schock,Appl.Phys.A:Mater.Sci.Process.A69,131?1999?

.

FIG.4.Semi-logarithmic plot of J ?J SC vs V ?R S J under illumination for the Cu(InAl)Se 2and Cu(InGa)Se 2devices.

Downloaded 03 Jun 2010 to 121.15.171.100. Redistribution subject to AIP license or copyright; see https://www.wendangku.net/doc/206183098.html,/apl/copyright.jsp