heck反应的综述

Tetrahedron report number 743

Non-conventional methodologies for transition-metal catalysed

carbon–carbon coupling:a critical overview.

Part 1:The Heck reaction

Francisco Alonso,a,*Irina P.Beletskaya b,*and Miguel Yus a,*

a

Departamento de Qu?

′mica Orga ′nica,Facultad de Ciencias and Instituto de S?′ntesis Orga ′nica (ISO),Universidad de Alicante,Apdo.99,E-03080Alicante,Spain

b

Department of Chemistry,Lomonosov Moscow State University,Vorob’evy Gory,119992Moscow,Russia

Received 10August 2005Available online 29September 2005

Contents

1.

General introduction ..........................................................117721.1.Substrates..............................................................117731.2.Catalytic systems ........................................................117731.3.Solvents ...............................................................

117741.3.1.Supercritical ?uids (SCFs)...........................................117741.3.2.Ionic liquids (ILs)..................................................117741.3.3.Fluorous media ...................................................117751.3.4.Aqueous solvents ..................................................117751.4.Reaction conditions ......................................................

117751.4.1.Physical activation .................................................

117761.4.1.1.Microwave ...............................................117761.4.1.2.Ultrasound ................................................117761.4.1.3.High pressure .............................................

117761.4.2.Physicochemical activation ...........................................

11776

0040–4020/$-see front matter q 2005Elsevier Ltd.All rights reserved.

doi:10.1016/j.tet.2005.08.054

Tetrahedron 61(2005)11771–11835

Keywords :Heck reaction;Supercritical ?uids;Ionic liquids;Fluorous media;Aqueous solvents;Microwave;Ultrasound;High pressure;Nano?ltration;Microreactors;Ball-milling conditions.

Abbreviations :A,ampere;AAEMA,deprotonated form of 2-(acetoacetoxy)ethyl methacrylate;acac,acetylacetonate;Ad,adamantyl;A336,tricaprylmethylammonium chloride;atm,atmosphere;bbim,1,3-di-n -butylimidazolium;b ,block copolymer;bmim,1-butyl-3-methylimidazolium;BINAP,2,20-bis(diphenylphosphino)-1,10-binaphthyl;Boc,tert -butoxycarbonyl;BTF,benzotri?uoride (a ,a ,a -tri?uorotoluene);Cbz,benzyloxycarbonyl;co ,copolymer;COD,1,5-cyclooctadiene;Cy,cyclohexyl;DAB,1,4-diaminobutane;dba,dibenzylideneacetone;DBU,1,8-diazabicyclo[5.4.0]undec-7-ene;DEA,N ,N -diethylacetamide;DEC,dendrimer-encapsulated catalyst;dendr,dendrimer;DIPEA,diisopropylethylamine;DMA,N ,N -dimethylacetamide;DMF,dimethylformamide;DMG,N ,N -dimethylglycine;dppp,1,3-diphenylphosphinopropane;EDG,electron-donating group;EWG,electron-withdrawing group;Fc,ferrocenyl;F-dppp,?uorous-tagged 1,3-bis(diphenylphosphino)propane;HDAPS,N -hexadecyl-N ,N -dimethyl-3-ammonio-2-propanesulfonate;Hex,hexyl;IL,ionic liquid;LDH,layered double hydroxide;M,metal;MCM-41,hexagonally packed mesoporous molecular sieves;MW,microwave;Nf,nona?ate (nona?uoro-n -butane-1-sulfonyl);NMP,N -methylpyrrolidinone;P c ,critical pressure;PAMAM,poly(amidoamine);PEG,poly(ethylene glycol);pmim,1-n -pentyl-3-methylimidazolium;PNIPAM,poly(N -isopropylacrylamide);PNP,p -nitrophenyl;PS,polystyrene;Py,pyridyl;RCM,ring-closing metathesis;ROMP,ring-opening metathesis polymerisation;rt,room temperature;SAPO,silico aluminophosphate;sc,supercritical;SCF,supercritical ?uid;SCM,shell cross-linked micelles;SDS,sodium dodecyl sulfate;TBAA,tetra-n -butyl ammonium acetate;TBAB,tetra-n -butyl ammonium bromide;TBAC,tetra-n -butyl ammonium chloride;TBAF,tetra-n -butyl ammonium ?uoride;TEAC,tetraethylammonium chloride;Tf,tri?uoromethanesulfonyl;TPPDS,bis(p -sulfonatophenyl)phenylphosphane dipotassium salt;Na-TPPMS,mono(m -sulfonatophenyl)diphenylphosphane monosodium salt;m -TPPTC,tris(m -carboxyphenyl)phosphane trilithium salt;TPPTS,tris(m -sulfonatophenyl)phosphane trisodium salt;TXPTS,tris(4,6-dimethyl-3-sulfonatophenyl)phosphane trisodium salt;T c ,critical temperature;THF,tetrahydrofuran;THP,tetrahydropyranyl;TFA,tri?uoroacetic acid;Tol,tolyl;TOF,turnover frequency (mol of product per mol of catalyst h K 1);TON,turnover number (mol of product per mol of catalyst);Ts,p -toluenesulfonyl;ttmpp,tris-(2,4,5-trimethoxyphenyl)phosphane;wt,weight;XAFS,X-ray absorption ?ne structure.

*Corresponding authors.Tel./fax:C 34965903549;(F.A.;M.Y.);fax:C 7959381844;(I.P.B.);e-mail addresses:falonso@ua.es;beletska@org.chem.msu.ru;yus@ua.es

1.4.2.1.Micellar solutions (11776)

1.4.2.2.Microemulsions (11777)

1.4.3.Electrochemical activation (11777)

1.5.Miscellaneous non-conventional techniques (11777)

1.5.1.Nano?ltration (11777)

1.5.2.Microreactors (11777)

1.5.3.Ball-milling conditions (11778)

2.Objectives and organisation (11778)

3.Introduction to the Heck reaction (11778)

4.Substrates (11778)

4.1.Alternative arylating agents (11778)

4.2.Supported substrates (11782)

5.Catalytic systems (11785)

5.1.Ligands:ligand-free catalytic systems (11785)

5.2.Catalysts:supported catalysts (11787)

5.2.1.Carbon (11787)

5.2.2.Metal oxides and other inorganic materials (11788)

5.2.3.Clays,zeolites and molecular sieves (11795)

5.2.4.Polymers (11798)

5.2.5.Dendrimeric systems (11803)

6.Solvents (11806)

6.1.Supercritical?uids (11806)

6.2.Ionic liquids (11808)

6.3.Fluorous media (11814)

6.4.Aqueous solvents (11817)

7.Reaction conditions (11820)

7.1.Physical activation (11820)

7.1.1.Microwave (11820)

7.1.2.Ultrasound (11822)

7.1.3.High pressure (11822)

7.2.Physicochemical activation (11823)

7.2.1.Micellar solutions (11823)

7.2.2.Electrochemical activation (11824)

8.Miscellaneous non-conventional techniques (11824)

8.1.Nano?ltration (11824)

8.2.Microreactors (11825)

8.3.Ball-milling conditions (11826)

9.General conclusions (11826)

References and notes (11826)

Biographical sketches (11835)

1.General introduction

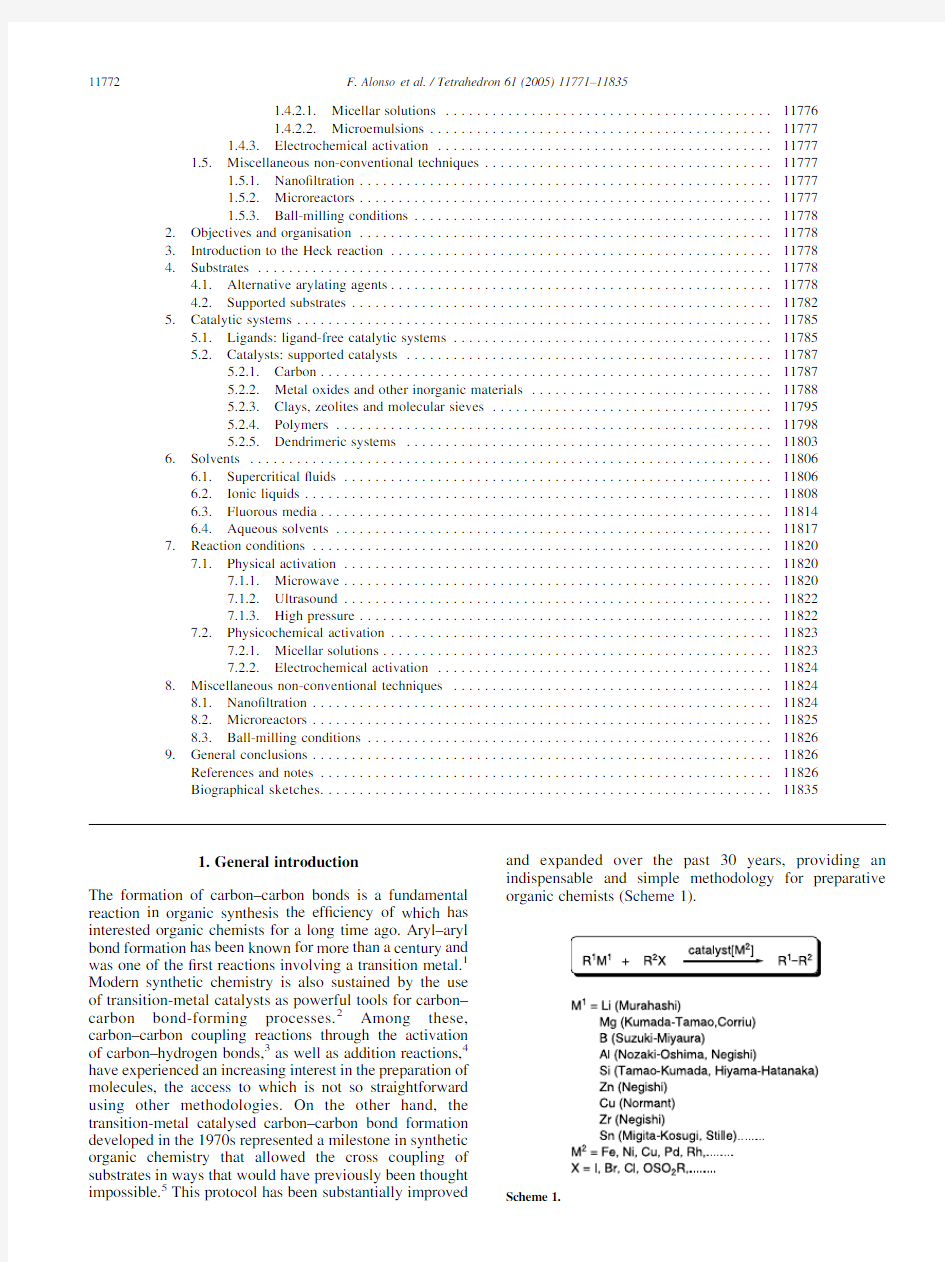

The formation of carbon–carbon bonds is a fundamental reaction in organic synthesis the ef?ciency of which has interested organic chemists for a long time ago.Aryl–aryl bond formation has been known for more than a century and was one of the?rst reactions involving a transition metal.1 Modern synthetic chemistry is also sustained by the use of transition-metal catalysts as powerful tools for carbon–carbon bond-forming processes.2Among these, carbon–carbon coupling reactions through the activation of carbon–hydrogen bonds,3as well as addition reactions,4 have experienced an increasing interest in the preparation of molecules,the access to which is not so straightforward using other methodologies.On the other hand,the transition-metal catalysed carbon–carbon bond formation developed in the1970s represented a milestone in synthetic organic chemistry that allowed the cross coupling of substrates in ways that would have previously been thought impossible.5This protocol has been substantially improved and expanded over the past30years,providing an indispensable and simple methodology for preparative organic chemists(Scheme1

).

Scheme1.

F.Alonso et al./Tetrahedron61(2005)11771–11835 11772

In spite of the fact that it would seem that most of the research on developing carbon–carbon coupling strategies has been done,some new challenges on this topic have emerged in the narrow boundary between the20th and21st century.A new mentality of the organic chemist is focussed on the design of new tendencies and methodologies able to make the already known chemical transformations simpler, faster,cheaper,greener and in general,more ef?cient processes.In particular,increasing attention has been paid to the‘green chemistry’of these processes,this concept being understood as the set of principles6that reduce or eliminate the use or generation of hazardous substances.7 The idea of atom-economical reactions may be also a useful concept in helping to promote thinking in the direction of sustainable chemistry.8In order to achieve all the goals mentioned above,several valuable and distinctive tech-niques,9which do not?nd daily use in the laboratory,can be applied by the organic chemist to operate at different levels including(a)the type of substrates,(b)the catalyst,(c)the solvent,(d)the reaction conditions,(e)the separation techniques and(d)the reaction vessel.An introductory commentary to remark the importance of any of these parameters follows.

1.1.Substrates

The majority of studies of metal-catalysed cross-coupling reactions involve a halide or sulfonate as the electrophile and an organometallic reagent as the nucleophile in which the carbon atoms to be coupled are all sp2-hybridized.There is,however,a substantial need for the development of successful cross-coupling reactions involving either alkyl halides or https://www.wendangku.net/doc/7e2513454.html,anic halides also take part in Heck-type reactions.On the other hand,all these processes have in common some lack of atom economy,8since the corresponding inorganic salts are obtained and require proper isolation and treatment.

In the past decade,there have been developments in palladium-catalysed coupling systems for Heck,Suzuki, Stille and Sonogashira reactions among others,as a consequence of the great interest in the development of coupling partners that are both more economical and readily accessible.In spite of the fact that organoboranes and organostannanes have been the reagents of choice for some of these reactions,there are still some drawbacks in their use:certain organostannanes such as the trimethyltins, Me3SnX and their by-products are toxic,whereas organo-boranes have a lack of stability,particularly alkyl-and alkynylboranes.

Consequently,the search for novel substrates for the cross-coupling reactions has been the focus of much attention,for example,carboxylic acids,anhydrides and esters,as well as sulfonium salts,thiol esters and thioethers,have emerged as interesting alternatives to aryl halides.10In particular, carboxylic acids do not generate large amounts of waste and they work in the absence of phosphane ligands.There is, however,no general advantage in terms of atom economy and their generation in not always readily accessible, producing stoichiometric amounts of salts as by-products. The Stille,Suzuki and Kumada reactions with alkyl and aryl ?uorides is a recent and promising research area leading to the cross-coupled products under generally mild reaction conditions.11The stability of vinylic tellurides has also been used in palladium-catalysed cross-coupling reactions for the preparation of stereochemically de?ned enynes and enediynes.The fact that these reagents work in the presence of sensitive functional groups and under mild reaction conditions makes them interesting substitutes for vinylic halides and tri?ates.12

On the other hand,potassium tri?uoro(organo)borates are promising alternatives to the use of the known organo-boronic acids,exhibiting higher reactivity and exceptional stability.13Germanium reagents have been recently used in cross-coupling reactions,14exhibiting intermediate reactivity between that of organotin15and organosilicon compounds,16avoiding the toxicity of certain organotin reagents and being more reactive than silicon.

In recent years,an increasing interest has been shown in the possibility of anchoring the substrates to a solid support, facilitating their use in automated parallel synthesis in a combinatorial manner.The main advantages of these solid-phase transformations are the avoidance of tedious workup procedures,the quasi high-dilution effect(high yields by employing an excess of reagent),amenability to automatisation and the non-interference of various functionalities in the building blocks on a solid support.17 1.2.Catalytic systems

The form in which the catalyst is present in the reaction media is fundamental to drive the reaction in an effective manner.A wide range of possibilities can be explored, depending on the different combinations of the components of the catalytic system,for example,the catalyst can be present as nanoparticles,ligandless,unsupported, supported,etc.

Transition-metal nanoparticles have attracted a great deal of attention during the last10years as catalytic systems with great potential,due to the large surface area of the particles. It has been suggested that metal colloids are very ef?cient catalysts because of the ratio of atoms remaining at the surface.In fact,these catalysts are microhetereogenous systems bearing nanoparticles.The application of transition-metal nanoparticles to the formation of carbon–carbon bonds is still,however,in its infancy.18

Recent interest in the development of environmentally benign syntheses and in minimising the cost of the precious metal catalysts has led to the development of polymer-bound metal catalysts for the carbon–carbon coupling reaction that maintain high activity and selectivity.The supported complexes can be recovered from the reaction mixtures,they do not contaminate the product solution and they can be recycled and used for the rapid production of compound libraries.Often,however,there is metal leaching during the course of the reaction and they are often not recyclable.As a result,many efforts have been focussed on the development of new ligand-derivatised polymeric supports for the attachment of metals and on the design of new methods to increase both the activity and the selectivity.19In particular,dendrimers as soluble supports

F.Alonso et al./Tetrahedron61(2005)11771–1183511773

have recently attracted much attention in homogeneous catalysis,since these well-de?ned macromolecular struc-tures enable the construction of precisely controlled catalyst structures.Moreover,the globular shapes of the higher generations of dendrimers are particularly suited for membrane?ltration.20

Alternatively,the immobilisation of catalysts can be effected on inorganic matrices,having several important potential advantages such as:(a)the remarkable ease of handling and use,(b)reduced product contamination by having the catalyst fully bound to the solid support,(c) relatively safe handling owing to full chemisorption of the possible toxic chemicals,(d)reduced environmental impact upon work-up,(e)good thermal and chemical stabilities,(f) good dispersion of the active catalytic sites,with a signi?cant improvement in the reactivity and(g)improve-ment in the reaction selectivity,due to the constraints of the pores and the characteristics of surface adsorption.21In general,they offer superior chemical,mechanical and thermal stability compared with the use of organic polymeric supports.

1.3.Solvents

Since most of the chemical reactions are performed in the solution phase,the solvent plays a crucial role to implement any transformation,either on a laboratory or industrial scale.22For a given process,the solvent will always condition the work-up,recycling and disposal techniques employed for the appropriate treatment of the reaction mixture and every one of its components.Within the context of green and sustainable chemistry,the endeavour to replace volatile organic solvents in organometallic catalysis for alternative more practical and environmentally friendly solvents must be highlighted.23Interesting approaches include catalysis based on aqueous systems,ionic liquids, supercritical media,or?uorinated phases. Nonetheless,it is known that many reactions proceed ef?ciently in the solid state.In fact,in some cases,solid-state organic reactions occur more ef?ciently and selectively than their solution counterparts,since molecules in a crystal are arranged tightly and regularly.In addition,the solvent-free reactions make syntheses simpler for process and handling,saving energy and preventing solvent waste, hazards and toxicity.24

1.3.1.Supercritical?uids(SCFs).Supercritical?uids are well established as useful solvents for extraction,chroma-tography and a few specialised reactions.25In spite of the fact that they have been used for large-scale industrial production for most of the20th century,only during the last decade have their special properties made them attractive solvents for modern synthetic chemistry.25d,26The proper-ties of SCFs are different from those of ordinary liquids and gases and are tunable simply by changing the pressure and temperature.They form a single-phase mixture with gaseous reactants,sometimes avoiding a rate-limiting mass-transfer step and therefore,enhance the reaction rates. scCO2is readily accessible,with a T c of318C and a P c of 73atm and is abundant,inexpensive,non-?ammable,non-toxic and environmentally benign.Non-polar organic solvents have a high solubility in scCO2and the solubility of polar,ionic,or polymeric compounds can be increased by the addition of a polar additive or an appropriate surfactant. In addition,scCO2facilitates the separation of reactants, catalysts and products,being a substitute for environ-mentally less acceptable solvents.27

Water near its critical point(T c3748C and P c218atm)also offers environmental advantages and possesses properties very different from those of ambient liquid water.The dielectric constant is much lower and the formation of hydrogen bonds is less favoured.As a result,high temperature water behaves like many organic solvents in allowing a high solubility of organic compounds in near-critical water and complete miscibility in supercritical water.28

1.3.

2.Ionic liquids(ILs).Ionic liquids can be generally de?ned as liquid electrolytes composed entirely of ions.By applying the melting point criterion,they can be considered as salts with a melting point below the boiling point of water.They are,however,better described as liquid compounds that display ionic-covalent structures.Most ILs have an organic cation and an inorganic polyatomic anion.The most commonly used cations in room temperature ionic liquids are alkylammonium,alkylphos-phonium,29N,N0-dialkylimidazolium and N-alkylpyri-dinium cations and the most commonly utilised alkyl chains are methyl,ethyl,butyl,hexyl,octyl and decyl. Although the pyridinium-and imidazolium-based chloro-aluminate ionic liquids share the disadvantage of being reactive with water,the more recent tetra?uoroborate, hexa?uorophosphate,nitrate,sulfate and acetate salts are stable towards hydrolysis.Their physical and chemical properties can be?nely tuned for a range of applications by varying the cations or anions.30

This fascinating group of chemicals exhibits a great potential to improve development in organic chemistry, due to their particular properties:a very wide liquid range, relatively wide electrochemically stable window,good electrical conductivity,high ionic mobility with strong ion–ion interactions,negligible vapour pressure,non-?ammability,excellent chemical and thermal stability and ability to act as catalysts.Reactions in ILs have different thermodynamic and kinetic behaviour,which often lead to improved process performance.Moreover,ILs allow an enhanced stability of organometallic reagents and bio-catalysts and an easy recovery,as well as possible recycling of homogeneous catalysts.

The potential for recyclability,ability to dissolve a variety of materials and the non-volatile nature of the ILs are some of their unique attributes responsible for their popularity. Although originally studied in electrochemistry,ILs are currently being explored as environmentally benign solvent substitutes in a variety of applications such as chemical synthesis,liquid–liquid separations,extractions,dissolution processes,catalysis,biocatalysis and polymerisation.31 More recently,they have also found application in asymmetric synthesis,32as well as in the synthesis of nanoparticles and other inorganic nanostructures.33

F.Alonso et al./Tetrahedron61(2005)11771–11835 11774

It has recently been shown that there is a possibility of performing chemical reactions in ILs in conjunction with microwave irradiation,34as well as with separation routes utilising binary ionic liquid–scCO2systems.35

In spite of the fact that ILs are generally considered as environmentally friendly substitutes for volatile organic solvents,the environmental fate and any potential toxicity issues for most ionic liquids are not known,particularly with respect to alkylimidazolium systems.36In fact,so far,only a few toxicological and ecotoxicological data are available for this group of chemicals.More information seems to be needed in order to assess ILs with regard to sustainability and the principles of green chemistry.37On the other hand, although ILs are easy to obtain,their conventional preparation involves an excess of solvents and alkyl halides and,therefore, new efforts have emerged in a direction to minimize,at least,the amount of solvents in the reaction medium.38 1.3.3.Fluorous media.Fluorous chemistry can be considered as a complementary type of liquid-phase synthetic and separation methodology involving the use of ?uorine-containing reagents and solvents.39Fluorous solvents offer a unique perspective on a chemical reaction that allows one or more stages to be carried out without the need for volatile or noxious organic solvents,making the process simpler and more energy ef?cient and reducing the separation steps.Per?uoroalkanes,per?uorodialkyl ethers and per?uorotrialkylamines are the most common ?uorous solvents used,which are practically non-toxic. These solvents can be used in conjunction with a?uorous reaction component(reagent,catalyst,pre-catalyst,ligand, product,scavenger,protecting group,etc.),to which a ?uorous tag has been deliberately attached in order to make it soluble in?uorous solvents.It must be taken into account that the attachment of?uorous ponytails can signi?cantly change the reactivity of the?uorous reaction component, the insertion of two or three methylene groups before the ?uorous ponytail being necessary,in many cases,to decrease their strong electron-withdrawing effects.

The foundation of this methodology resides in the fact that the?uorous solvent has a low miscibility with common organic solvents.At a certain increased temperature,it is miscible with organic solvents but,when cooled,it splits into a biphasic system.A?uorous biphasic system can therefore,consist of a?uorous phase containing a?uorous-soluble reaction component and a second product phase, which may be any organic or non-organic solvent with limited solubility in the?uorous phase.40The?uorous biphasic reaction at the operating temperature can proceed either in the?uorous phase or at the interface of the two phases,depending on the solubilities of the reactants in the ?uorous phase.When the reaction is complete,simply cooling the system makes the?uorous solvent immiscible in the organic phase.The?uorous biphasic system therefore, combines the advantages of a one-phase reaction with biphasic product separation.

The?uorous biphasic concept has been successfully applied in stoichiometric chemical reactions utilising organic, inorganic,or organometallic?uorous-soluble reagents. Because of the nature of the?uorous media,the application of?uorous reagents is limited to apolar substrates,since the reactions of polar substrates may be too slow for practical applications.This concept has also found application in catalysis(where only transition-metal complexes have been converted into?uorous soluble entities through ligand modi?cation),in multistep organic synthesis and in combinatorial chemistry.41

The?uorous phase,together with ionic liquid approaches and supercritical?uid systems,offers a whole new repertoire of solvents that overcome many of the problems of volatile organics.

1.3.4.Aqueous solvents.In the most recent decades,the use of water as a reaction solvent or co-solvent has received much attention in synthetic organic chemistry,with some-times surprising and unforeseen results.42Despite the different advantages that the previous mentioned solvents can offer,water can still be considered as a unique solvent. Moreover,water is the‘solvent of Nature’and,therefore,its use in common chemistry can be regarded as biomimetic and biocompatible.There are many potential reasons to replace the classical organic solvents by water,such as cost, safety and environmental concern.In fact,aqueous procedures are often referred to as green,environmentally friendly,or benign.In addition,the unique solvation properties of water have been shown to have bene?cial effects on many types of organic reactions in terms of both the rate and selectivity.Furthermore,experimental pro-cedures may be simpli?ed,since isolation of organic products and recycling of water-soluble catalysts and other reagents can be achieved by simple phase separation. The main obstacle to the use of water as reaction solvent is the negligible solubility of the majority of organic compounds in water.This problem can be addressed by using aqueous organic solvents or phase-transfer agents.As will be shown in this review,aqueous-phase transition-metal catalysis,including asymmetric catalysis,has emerged as an important tool in the formation of carbon–carbon bonds.43

1.4.Reaction conditions

While some reactions occur spontaneously,most of them require activation.For carbon–carbon coupling reactions, chemical activation modes(i.e.,catalysis)are indispensable in order to make processes effective and selective.The association of several activation modes,however,emerges as a powerful synthetic strategy when the respective kinetic effects are convergent.Besides the classical thermal activation mode,new methods have emerged in the recent years,such as physical or physicochemical activation techniques,among others.Thus,microwaves and ultrasonic and high-pressure techniques have been added to the chemist’s repertoire as physical methods for accelerating chemical reactions.On the other hand,physicochemical activation results from interactions between the medium and the reactive molecules and can arise from the solvent or from added complexing molecules.Physicochemical activation can be applied through the action of solvophobic effects(microemulsions and vesicles),host–guest chemistry,etc.

F.Alonso et al./Tetrahedron61(2005)11771–1183511775

1.4.1.Physical activation.

1.4.1.1.Microwave.Microwaves are a form of electro-magnetic radiation.When molecules with a permanent dipole are placed in an electric?eld,they become aligned with that?eld.If the electric?eld oscillates,then the orientations of the molecules will also change in response to each oscillation.Most microwave ovens operate at

2.45GHz,wavelength at which oscillations occur4.9! 109times per second.Molecules subjected to this microwave radiation are extremely agitated as they align and realign themselves with the oscillating?eld,creating an intense internal heat that can escalate as quickly as108C per second.Non-polar molecules such as toluene,carbon tetrachloride,diethyl ether and benzene are microwave inactive,while polar molecules such as DMF,acetonitrile, dichloromethane,ethanol and water are microwave active. This technique proves to be excellent in cases where traditional heating has a low ef?ciency because of poor heat transmission and,hence,local overheating is a major inconvenience.44

Microwave-assisted synthesis is a relatively young science of increasing research interest,as evidenced by the number of papers and reviews appearing in the literature.45The most important advantage of microwave-enhanced chemistry is the reduction in the reaction times.Reactions that require hours or days of conventional heating may often be accomplished in minutes under microwave heating.More-over,reactions are not only faster,but proceed with higher purity and,consequently,higher yields.The dramatic acceleration and increased purity and yields of micro-wave-assisted reactions make them attractive to the increased demands in industry and,in particular,for combinatorial drug discovery.46In addition to being energy ef?cient,the possibility of employing milder and less toxic reagents and solvents,or even solvent-free systems,offers a further advantage of this heating technology.

1.4.1.

2.Ultrasound.Ultrasound generally designates acoustic waves with frequencies in the range of20–100MHz.This energy is insuf?cient to cause chemical reactions,but when ultrasound travels through media a series of compressions and rarefactions are created,the rarefaction of liquids leading to cavities.During rarefaction, the negative pressure developed by power ultrasound is enough to overcome the intermolecular forces binding the ?uid and tear it,producing cavitation bubbles.The succeeding compression cycle can cause the microbubbles to collapse almost instantaneously with the release of large amounts of energy.The enormous rise in local temperatures and pressures produces a dramatic bene?cial effect of reaction acceleration,with relatively short times being required for completing the reaction such that the decomposition of thermally labile products is minimised.47 The frequency of ultrasound has surprisingly little in?uence on the reactions within the range in which cavitation occurs. Of signi?cance is the fact that ultrasound affects both homogeneous and heterogeneous reactions.

1.4.1.3.High pressure.Pressure represents a mild non-destructive activation mode,generally respecting the molecular structure by limiting decomposition or further evolution of the products.Therefore,the speci?c effects of high pressure can be of important value for organic synthesis.48The kinetic pressure effect is primarily determined by the variation of volume due to changes in the nuclear positions of the reactants during the formation of the transition state.Related to volume requirements are steric effects since the bulkiness of the molecules involved in the transition state conditions the magnitude of the steric interactions.As a consequence,pressure affects volume changes and should have an effect on steric congestion. As a mild activation mode,pressure may be considered of value in the synthesis of thermally fragile molecules, permitting a lowering of the temperature.In addition,the selectivity is generally preserved or even improved under such conditions.

On the other hand,pressure can be combined with solvophobic effects.The effect of pressure on organic reactions in aqueous solutions is complex.The activation volume relative to hydrophobic effects is positive(meaning deceleration by pressure),whereas the activation volume due to hydrogen bonding is negative.In addition, electrostatic effects may also be involved in many reactions (negative activation mode).Nevertheless,the combination of pressure and solvophobic activation may be an interesting method to increase the reactivity of reluctant polar molecules.

1.4.

2.Physicochemical activation.

1.4.

2.1.Micellar solutions.Micelles are dynamic colloidal aggregates formed by amphiphilic surfactant molecules.These molecules can be ionic,zwitterionic,or non-ionic,depending on the nature of their head groups, their micelles being classi?ed in the same way.In dilute solutions,amphiphile molecules exist as individual species in the media and these solutions have completely ideal physical and chemical properties.As the amphiphile concentration increases,aggregation of monomers into micelles occurs and,as a consequence,these properties deviate gradually from ideality.This concentration is called the critical micellisation concentration.

During the formation of micelles,head group repulsions are balanced by hydrophobic attractions and for ionic micelles, also by attractions between head groups and counterions. Hydrogen bonds can be also formed between adjacent head groups.

It is well known that the rates and pathways of all kinds of chemical reactions can be altered by performing the reactions in micellar media instead of pure bulk solvents.49 Micelles are able to(a)concentrate the reactants within their small volumes,(b)stabilise substrates,intermediates or products and(c)orientate substrates so that ionisation potentials and oxidation–reduction properties,dissociation constants,physical properties,quantum ef?ciencies and reactivities are changed.Thus,they can alter the reaction rate,mechanism and the regio-and stereochemistry.For many reactions,rate increments of5–100-fold over the reactions in homogeneous solutions have been reported.In some cases,rate increments may be much higher and increments in the order of106-fold have been observed.

F.Alonso et al./Tetrahedron61(2005)11771–11835 11776

1.4.

2.2.Microemulsions.When water is mixed with an organic liquid immiscible with water and an amphiphile, generally a turbid milky emulsion is obtained which,after some time,separates again into an aqueous and an organic phase.On the water-rich side,the mixtures consist of stable dispersions of oil droplets in water,which coagulate with rising temperature.A spongelike structure is obtained if the mixtures contain approximately equal amounts of water and oil.On the oil-rich side,dispersed water droplets are found, which coagulate with decreasing temperature.The size of the domains is a function of the amphiphile concentration and the volume fractions of water and oil.50

Since microemulsions contain both a polar component (water)and a non-polar component(oil),they are capable of solubilising a wide spectrum of substrates.The mechanism of solubilisation is similar to that in micellar solutions.The micelles are replaced by the oil domains,which are capable of solubilising all kinds of hydrophobic substances.The solubilisation of polar substances takes place analogously through the aqueous domains of the microemulsion.The solubilisation capacity of microemulsions is generally superior to that of the micellar solutions and can therefore, affect the rate and course of a certain reaction.

1.4.3.Electrochemical activation.Electrochemistry represents a convenient synthetic method in which electrons constitute clean and energetically ef?cient reactants.The development of the potentialstat turned electrochemistry into a common tool for organic synthesis.51In spite of the procedural simplicity,absence of side products derived from reagents and high ability for accomplishing selective oxidoreductions under very mild conditions,electro-synthesis still appears to be undervalued,even though some industrial-scale work has demonstrated its appealing features.

The apparatus required for electrosynthesis can be as simple as a beaker containing a pair of electrodes connected to a direct-current voltage source.A stirrer,thermometer,jacket, inert gas inlet,or any combination,can be added.For some reactions,the separation of the electrodes by a diaphragm is mandatory to prevent the products from one electrode diffusing to the other and being destroyed.A proper solvent and supporting electrolyte will be also required.

In some cases,chemical techniques turn out to be quite dif?cult in the preparation of certain organometallic species. Electrochemistry can,however,provide an easy way to generate a desired oxidation state of a metal complex that becomes the active catalytic species for an organic reaction. In the particular case of redox processes,the active catalytic species can be recycled continually by the electrode oxidation or reduction reactions.In these processes,the electrons are consumed stoichiometrically with respect to the substrate.Therefore,it is the electrons that are used as clean,controlled and non-polluting redox agents.In non-redox reactions,electrochemistry is used only to generate the catalytic system.It has been observed that electro-generated species can be more reactive than their chemically prepared analogues.521.5.Miscellaneous non-conventional techniques

The techniques mentioned below are rather speci?c and so far have only been described for a limited number of examples.

1.5.1.Nano?ltration.It is important to recognise that the total ef?ciency of synthesis is also conditioned by the ability to separate the products from the unchanged starting materials,excess reagents and catalysts.Within the green chemistry context,it is also interesting to develop techniques that enable the separation and re-use of catalysts and reagents.Thus,separation protocols additional to those described above(i.e.,per?uorinated systems,sc?uids,ionic liquids,solid-phase supported reagents and catalysts,etc.), which are easily automated to enable rapid puri?cation by simple operations,are welcome.53

In the?eld of homogeneous catalysis,separation of the catalyst from the product mixture is rather complicated, preventing large-scale industrial processes.An interesting and promising development in the area of homogeneous catalyst recycling is the attachment of homogeneous catalysts to soluble organic supports.In this way, macromolecular catalysts anchored on soluble supports such as polymers and dendrimers are created,which can be recovered by ultra-or nano?ltration techniques and re-used again.

Recently,solvent-stable ultra-and nano?ltration mem-branes have been introduced showing high retentions for medium-sized soluble molecules.54In the?eld of mem-brane?ltration,ultra-and nano?ltration techniques are de?ned to retain macromolecules with dimensions between 8–800and0.5–8nm,respectively.

1.5.

2.Microreactors.Microreactor devices consist of a network of micron-sized channels(10–300m m),with a high surface-area-to-volume,etched into a solid substrate.55For solution-based chemistry,the channel networks are con-nected to a series of reservoirs containing chemical reagents and products to form the complete device with overall dimensions of a few cm.Reagents can be brought together in a speci?c sequence,mixed and allowed to react for a speci?ed time in a controlled region of the channel network using electrokinetic(electro-osmotic and electrophoretic)or hydrodynamic pumping.For electrokinetically driven systems,electrodes are placed in the appropriate reservoirs to which speci?c voltage sequences can be delivered under automated computer control.This control offers an effective method of moving and separating reagents within a microreactor,without the need for moving parts.Hydro-dynamic pumping uses conventional,or microscale,pumps to manoeuvre solutions around the channel network,but, this technique has the disadvantage of requiring either large external pumps or complex fabrication of small moving parts.

Many reactions have been demonstrated to show altered reactivity,product yield and selectivity when performed in microreactors,as compared with conventional benchtop glassware.In fact,the desired product is often produced in higher yield and purity and more quickly.Process

F.Alonso et al./Tetrahedron61(2005)11771–1183511777

parameters such as pressure,temperature,residence time and?ow rate are more easily controlled,thus minimising risk and side reactions.Furthermore,solvent-free mixing, in situ reagent generation and integrated separation techniques can all help to make the chemistry greener.56 One of the immediate applications is therefore in drug and process discovery,where the generation of compounds with different reagents under variable conditions is an essential factor and also allows,in a short time and with greater safety,a process to be transferred to the pilot and production scale.57

1.5.3.Ball-milling conditions.Ball-mill chemistry is of interest because of the mild conditions under which it operates and also the absence of any solvent and easy work up.This technique has,however,been scarcely studied and applied to very few reactions.58Apparently,the rotation of the steel balls creates a high pressure in contact with the walls of the container,allowing the reagents to interact and promoting the process.

2.Objectives and organisation

In principle,we wanted to present in this report the application of recent non-conventional methodologies to the transition metal-catalysed carbon–carbon coupling reaction.Heck,Suzuki,Sonogashira,Stille,Negishi and Kumada reactions,among others,were the reactions originally to be covered.Because of the abundant literature found on this topic,however,we decided to dedicate this ?rst part only to the Heck reaction,whereas the rest of the reactions will be studied in the second part in due course.

Nonetheless,the above introduction is common for any of the parts of the review.Other carbon–carbon bond forming reactions such as the transition-metal catalysed coupling reactions through the activation of carbon–hydrogen bonds, nucleophilic substitution(Tsuji–Trost reaction),or acyla-tion of carbon nucleophiles are beyond the scope of this review.Some of the reports dealing with the diverse topics to be tackled here have been previously and properly reviewed elsewhere and will not be covered to their full extent.Instead,a summary together with the more recent contributions until2004will be provided.The review is organised according to the sub-headings presented in the general introduction,taking into account the different components and variety of conditions involved in the Heck reaction.Many of the contributions to this review are also analysed from a critical point of view,with the aim of discussing the advantages and disadvantages that the different techniques offer and trying to select the best choice,when possible.A short conclusion can be found at the end of each section.

3.Introduction to the Heck reaction

The Heck reaction is broadly de?ned as Pd(0)-mediated coupling of an aryl or vinyl halide or sulfonate with an alkene under basic conditions.Since its discovery,this methodology has been found to be very versatile and applicable to a wide range of aryl species and a diverse range of ole?ns(Scheme2).59The major steps of the general and traditional mechanism for the Heck reaction are depicted in Scheme3.60

4.Substrates

4.1.Alternative arylating agents

In all the Heck reactions described in Scheme2,a stoichiometric amount of base is required to neutralise the acid that is formed during the reaction(see Scheme3).As a consequence,the corresponding equivalent amount of halide salt is obtained as waste.In the search for a cheap aryl source that does not lead to the formation of halide salts,de Vries et al.introduced the use of aromatic carboxylic anhydrides as the arylation source.61For instance,heating benzoic anhydride and n-butyl acrylate in a N-methylpyrrolidinone(NMP)solution containing PdCl2and NaBr at1608C for90min,led to the formation of(E)-n-butyl cinnamate with high conversion,90% selectivity and good yield.Although a catalytic amount of a chloride or bromide was necessary for optimal activity, phosphane ligands were not required.p-Methoxybenzoic anhydride and2-furanoic acid anhydride were also successfully used as arylation agents.A variety of ole?ns were arylated under similar conditions at140–1908C (Scheme4).Ole?ns with electron-withdrawing groups gave better yields,although,due to the relatively high reaction temperature,double-bond isomerisations and

less Scheme

2.

Scheme3.

F.Alonso et al./Tetrahedron61(2005)11771–11835 11778

regioselective arylations were observed in some cases.It is noteworthy that the only side products in the reaction are benzoic acid(easily recovered by extraction with hot water) and carbon monoxide(which could be transformed into carbon dioxide in industrial processes).

Further investigation on this topic by Shmidt and Smirnov showed that the use of lithium chloride instead of sodium bromide increased the catalyst activity and productivity, since chloride accelerates CO elimination from the oxidative addition product more than bromide.62

Goo b en et al.studied the decarbonylative ole?nation of aryl esters in an attempt to minimise the production of waste.63 Starting from the p-nitrophenyl ester of the carboxylic acid, the corresponding alcohol formed in the Heck reaction could be recycled back into the starting ester,with CO and water being the only by-products in the overall reaction.63a Lithium chloride and isoquinoline proved to increase the effectiveness and stability of the catalyst in such a manner that higher yields were obtained.A wide variety of benzoates of electron-de?cient phenols(e.g.,p-nitrophenol) were found to be suitable substrates,whereas both electron-rich and electron-poor ole?ns gave similar yields,with regioselectivities ranging from4:1to20:1(Scheme5).If we compare this methodology with that described above,the scope of this Heck ole?nation seems to be wider.The catalytic system,however,requires larger amounts of all of its components,as well as the presence of a substantial amount of isoquinoline that must be removed at the end of the process.The lower reactivity of the benzoic esters in comparison with the benzoic anhydrides is also re?ected in the reaction times.The above idea was extended recently to the use of isopropenyl arenecarboxylates as arylating agents in a salt-free medium.63b These arylating reagents were syn-thesised through a waste-free reaction involving ruthenium-catalysed addition of the carboxylic acids to propyne. Concerning the coupling reaction,instead of waste salts,CO and acetone are the only by-products,the volatility of which allows easy workup.Electron-rich and electron-de?cient aryl,heteroaryl and vinyl carboxylic acid esters were coupled with several ole?ns(styrene in most cases)in good to excellent yields(Scheme6).In contrast to the bene?cial features of the whole process,the reaction temperature is rather high and is probably the reason for the moderate regioselectivities generally obtained(5:1–15:1),except in the case of n-butyl acrylate(O50:1).

In the examples shown in Schemes4and5,there is the necessity to generate the starting material in an extra reaction step and separate the ole?n products from the carboxylic acids or phenols,these being practical dis-advantages for small-scale preparations.Goo b en et al. utilised mixed anhydrides of carbonic and aromatic carboxylic acids,easily prepared in situ by mixing the carboxylic acids with di-tert-butyl dicarbonate(Boc2O),as arylating agents in the Heck ole?nation.64Different aromatic and heteroaromatic carboxylic acids(including electron-rich carboxylic acids)were coupled mainly with styrene,to give the expected products in moderate to good yields(45–88%)and selectivities(5:1–28:1)(Scheme7). The reaction could be performed at a lower temperature (1208C),in comparison to the examples described above, although g-picoline was necessary to stabilise the

palladium Scheme

4.

Scheme

5.

Scheme

6.

Scheme7.

F.Alonso et al./Tetrahedron61(2005)11771–1183511779

and to avoid precipitation and loss of activity at reasonable reaction rates.

Myers et al.subjected a wide range of arenecarboxylates to ef?cient Heck-type decarboxylative coupling with ole?nic substrates under relatively mild reaction conditions and in short reaction times (Scheme 8).65The key additive,silver(I)carbonate,presumably functions both as a base and as a stoichiometric oxidant,enlarging the lifetime of the active catalyst.Good yields of the coupled products were obtained for both electron-rich and electron-withdrawing substituents on the aromatic carboxylic acid and ole?nic partners such as styrene,acrylates,(E )-ethyl crotonate and cyclohexenone.Certainly this methodology allows the direct use of aromatic carboxylic acids without any previous transformation,although the experiments suggested that at least one ortho substituent is necessary for successful decarboxylative palladation to occur.The relatively high catalyst loading and the large amount of the silver salt used are the main disadvantages of this methodology,which probably would limit its application to a laboratory scale.

In 1982,Blaser and Spencer demonstrated that aroyl chlorides could react with activated alkenes,under Pd(OAc)2catalysis in the presence of a tertiary amine at 120–1308C,to give the expected (E )-arylalkenes stereo-speci?cally and in high yields.66More recently,Miura et al.have utilised the rhodium complex [(C 2H 4)2RhCl]2for the catalytic decarbonylative Heck-type coupling of aroyl chlorides with styrene and n -butyl acrylate.67This methodology is very interesting,since the reactions are carried out in the absence of any phosphane ligand and base and with low catalyst loading,although re?uxing o -xylene (143–1458C)is needed to obtain the products with good yields at reasonable reaction times (Scheme 9).In addition,the workup seems to be signi?cantly simple,that is,?ltration,evaporation and washing with an appropriate

solvent such as methanol.A slow stream of nitrogen is,however,required to sweep away the HCl and CO evolved during the reaction,what can be a limitation for large-scale processes.Under similar conditions,cyclic alkenes such as norbornenes also reacted with aroyl chlorides accompanied by cyclisation to afford the indanone derivatives.

Andrus et al.have recently applied a palladium-catalysed decarbonylative Heck-type reaction of aroyl chlorides to the synthesis of resveratrol using palladium acetate,an imida-zolium carbene-type ligand and a non-coordinating amine base,N -ethylmorpholine.68The overall yield starting from the inexpensive resorcylic acid (53%)was higher compared to the aryldiazonium or mixed anhydride approach.Boronic acids have been used as arylating agents in Heck-type reactions by several groups.4b Uemura et al.showed,in 1994,that arylboronic acids reacted with alkenes in acetic acid at 258C in the presence of a catalytic amount of palladium(II)acetate,together with sodium acetate,to give the corresponding aryl-substituted alkenes in high yields.69Alkenylboronic acids also reacted with alkenes under similar conditions to give the corresponding conjugated dienes stereospeci?cally,but the product yields were lower compared with those from the arylboronic acids.A similar treatment of sodium tetraphenylborate (NaBPh 4)with alkenes afforded the corresponding phenylated alkenes in high yields,together with biphenyl and benzene as side products.Oxidative addition of a carbon–boron bond to Pd(0),formed in situ,to give an organopalladium(II)species was assumed to be the key step of these cross-coupling reactions.More recently,Lautens et al.utilised a rhodium complex to catalyse the coupling reaction of arylboronic acids and styrenes in an aqueous media (Scheme 10).70The best results were obtained with [Rh(COD)Cl]2and TPPDS as the water-soluble ligand.It was,however,necessary to add 0.5equiv of sodium dodecyl sulfate (SDS)as a phase-transfer agent to avoid hydrolytic deboronation when the

arylboronic acid had polar functional groups.Gene

?t et al.found out that,using m -TPPTC [tris(m -carboxyphenyl)-phosphane trilithium salt]as the water-soluble ligand instead of TPPDS,no SDS was necessary,due to the inherent surfactant effect of m -TPPTC.71This ligand exhibited a similar performance in comparison with TPPDS,but was shown to be superior to TPPTS under the same conditions depicted in Scheme 10,but in the absence of https://www.wendangku.net/doc/7e2513454.html,utens’methodology was very recently extended to the coupling of a wide variety of aryl-and hetero-arylboronic acids with acrylates,acrylamides and vinyl sulfones.72The high selectivities and yields obtained

were

Scheme

8.

Scheme

9.Scheme 10.

F.Alonso et al./Tetrahedron 61(2005)11771–11835

11780

believed to result from the use of the bulky,electron-rich, water-soluble ligand tert-butyl-amphos chloride[N-2-(di-tert-butylphosphino)ethyl-N,N,N-trimethylammonium chloride].

Different catalytic systems have been developed recently for the Heck-type reaction of boronic acids and electron-de?cient ole?ns(Scheme11).Pd(OAc)2,[Ru(p-cymene)Cl2]2and RhCl3were utilised as catalysts by Mori,73Brown,74Zou,75and their corresponding co-workers,respectively.Despite the palladium and rhodium catalytic systems exhibiting better yields,higher tempera-tures were also required in comparison with the ruthenium catalytic system.Stoichiometric amounts of Cu(OAc)2were needed as a re-oxidising agent for palladium and ruthenium, the latter including3-quinuclinidone as a base in order to obtain the highest turnover.

The groups of Jung and Larhed independently introduced molecular oxygen as a re-oxidising agent in the palladium(II)-catalysed coupling of organoboron compounds and ole?ns. The optimised catalytic system reported by Jung et al.was composed of10mol%Pd(OAc)2,O2and Na2CO3in DMF at508C for3–10h.76Under these conditions,electron-rich and electron-poor ole?ns could be coupled with several boronic acids and esters,with generally good yields and stereo-and regioselectivities.The catalyst loading was diminished to1mol%by Larhed et al.in a catalytic system composed of Pd(OAc)2,O2,N-methylmorpholine and 1.2mol%2,9-dimethyl-1,10-phenantholine in MeCN at 508C for3–24h.This oxidative Heck protocol was applied to the coupling of arylboronic acids with unsubstituted acrylates77a and electron-rich ole?ns.77b The internal regioselectivity observed for the coupling with n-butyl vinyl ether and enamides was attributed to the phenanthro-line ligand,which also seemed to mediate the re-oxidation of palladium(0)with molecular oxygen,allowing a low catalyst loading.

Together with boronic acids,arylsilanols78and arylstan-nanes78c,79have been used as arylating agents in the Heck reaction with electron-de?cient ole?ns.There are,however, some evident disadvantages of these materials,when compared with the carboxylic acid derivatives.Firstly, these starting materials are not so readily available,their preparation involving less common and more expensive reagents,with the corresponding generation of waste. Secondly,boric acid,silanols and stannanes are formed as by-products in the Heck reactions,which can make the puri?cation of the products dif?cult with a low possibility of recycling.Thirdly,the presence of large amounts of Cu(II) salts as re-oxidants,phosphanes and organic bases is required for a maximum ef?ciency.

Uemura et al.found that diphenyltellurium(IV)dichloride reacted with a variety of ole?ns in the presence of a catalytic amount of PdCl2,together with NaOAc in HOAc to afford the corresponding arylated(E)-ole?ns in variable yields (3–98%)(Scheme12).80A suitable oxidant such as tert-butyl hydroperoxide or copper(I)or copper(II)chloride had to be added for the reaction to proceed catalytically on palladium.The stereoselectivity was very high,except for acrylonitrile(Z/E26:74).Transmetallation of tellurium with palladium was suggested as the key step of the reaction. Alternatively,diaryltellurides could be used as arylating agents for a variety of ole?ns in the presence of Et3N as base and AgOAc as oxidant(40–99%product yield).81

As an alternative to the above reagents,Kamigata et https://www.wendangku.net/doc/7e2513454.html,ed aryldimethyltellurium iodides for the palladium-catalysed Heck-type reaction with electron-de?cient ole?ns and styrene,in the presence of a stoichiometric amount of silver(I)acetate.82For the telluronium salt partner,the best results were obtained when the aryl moiety bore electron-donating substituents at the para position,those at the ortho position retarding the reaction(Scheme13).The yields are good to excellent,although a3-fold excess(with respect to the ole?n)of the expensive silver acetate is needed for the anion exchange and oxidation steps in the catalytic cycle.In contrast with the reactions with organic tellurides,for which the crude mixtures must be puri?ed to remove the excess reagent,in the reactions with the telluronium salts the pure products were obtained by simple?ltration using silica gel to remove the solids in the reaction mixture. Unfortunately,the organic tellurides and tellurium salts are not commercially available.Diaryltellurium(IV)dihalides are normally prepared from TeCl4with activated arenes, arylmercury chlorides or arenediazonium

salts. Scheme

11.

Scheme

12.

Scheme13.

F.Alonso et al./Tetrahedron61(2005)11771–1183511781

Symmetrical diaryltellurides can be prepared from alkali tellurides and non-activated aryl halides,sodium telluride or potassium tellurocyanate and arenediazonium?uoro-borates,tellurium(IV)halides and arylmagnesium halides, or elemental tellurium and diarylmercury compounds.Alkyl aryl tellurides are the precursors of the corresponding telluronium salts and are generally prepared by sequential arylation–alkylation of sodium telluride or from organyl tellurolates,generated by tellurium insertion into organo-magnesium or organolithium reagents.83In short,the

preparation of these arylating agents represents a major disadvantage that adds to the toxic and mutagenic properties of the starting materials,tellurium and TeCl4,respectively, and to the possible toxicity of the organotellurium compounds.84

A variety of organoantimony compounds have also found application in the arylation of ole?ns with different catalytic systems,including:(a)triphenylstibine with AgOAc and catalytic Pd(OAc)2,85(b)diphenyl-and phenylantimony chloride with catalytic Pd(OAc)2under air,86(c)triaryl-antimony diacetates under PdCl2(MeCN)2catalysis87 and(d)triarylstibines88or tetraphenylantimony(V) carboxylates89in the presence of equimolecular amounts of a peroxide and catalytic amounts of Li2PdCl4or PdCl2 (see some selected examples in Scheme14).In spite of the fact that these antimony compounds cannot be considered as usual reagents,all of them have an interesting feature in common,namely that the coupling reactions can be carried out under very mild reaction conditions,normally at room temperature or508C.

Less common is the use of organolead(IV)compounds as arylating agents for ole?ns.Kang et al.described in1998for the?rst time that aryllead triacetates could be coupled with a variety of electronically different ole?ns under mild reaction conditions and palladium catalysis(see one example in Scheme15).90Most of the reactions proceeded at room temperature with moderate to good yields,although the homocoupling reaction competed in some of the experiments reported.It was presumed that the oxidative addition step was facilitated by the formation of the organolead trimethoxide,ArPb(OMe)3,to give a polar reactive intermediate,ArPdPb(OMe)3,which allowed the coupling under mild conditions.On the other hand,the aryllead triacetates are not commercially available and are rather toxic reagents.

Most of the alternative arylating agents presented in this report have the main advantage of minimising by-product formation,therefore facilitating the work-up.Except in the case of the carboxylic acids,however,the rest of the reagents are not commercially available and the generation of waste in their preparation is inevitable.In addition,rather high temperatures are needed for the coupling reactions in order to achieve reasonable conversions.

4.2.Supported substrates

Intermolecular Heck reactions on solid supports have been extensively used in synthetic organic and combinatorial chemistry,due to the easy accessibility of the starting halo-alkenes or-arenes and alkenes.The reactions involve immobilised aryl halides,mostly iodides,or iodonium salts with soluble alkenes,or immobilised alkenes with soluble aryl halides.When performed on the same type of resin and with the same catalytic system,the immobilisation of aryl iodides appears to be more bene?cial than that of alkenes. Two main protocols have been applied:(a)the standard Heck conditions[Pd(OAc)2,Ph3P or(o-Tol)3P,DMF,80–1008C],2–24h]and(b)the Jeffery conditions[Pd(OAc)2, Ph3P,TBAC,K2CO3,DMF,20–808C].The intramolecular Heck reaction on solid supports has found application in the preparation of macrocycles and heteroatom-containing ?ve-,six-and seven-membered rings,as well as in the construction of indoles,benzofurans,dihydroisoquinolines and benzazepines.The pseudo dilution effect exhibited by the starting material in the intramolecular version has led to an increased yield.Both inter-and intramolecular Heck reactions on a solid support have been recently reviewed17 and,therefore,it is not our objective to repeat all of this information here.Instead,we will deal with the more recent and representative examples and present a general con-clusion at the end of this section.

Morphy et al.observed that the use of low solvent volumes in solid-phase Heck reactions resulted in large increases in yield,compared with the standard dilution conditions.91 3-Iodobenzoyl chloride was reacted with Wang resin,the resulting aryl halide being coupled with ethyl acrylate under palladium catalysis,followed by resin cleavage with

TFA. Scheme

14.

Scheme15.

F.Alonso et al./Tetrahedron61(2005)11771–11835

11782

After reaction at608C for2h at standard dilution(1ml),a conversion of40%was observed,compared to80%when only0.05ml of solvent was used.The reaction was complete after18h for a low solvent volume with only 54%conversion under standard dilution conditions (Scheme16).The optimal amount of solvent represented %2m L/mg of resin,signi?cantly less than that required to totally swell the resin used and lead to a separate solvent phase.This methodology is certainly advantageous,since it minimises the use of solvent and provides high conversions under mild reaction conditions.Unfortunately,all reactions were performed on a very small scale(0.05mmol of resin-bound3-iodobenzoic acid)with excess of ethyl acrylate (2equiv)and Et3N(5equiv)and,therefore,the behaviour of this catalytic system on a larger scale remains uncertain.

A small library of cinnamate esters was prepared by Gene?t et al.,based on the use of a new stable silylated polystyrene, PS-SiMe2CH2Cl.92This chloromethyl resin was esteri?ed with various iodobenzoic acids(o-,m-and p-derivatives),followed by a cross-coupling reaction with ethyl acrylate in DMF in the presence of Pd(OAc)2-PPh3as the catalytic system,the latter transformation taking place with complete conversion.The expected esters were released from the resin by treatment with TBAF in THF(Scheme17).Owing to the dif?culties of eliminating the excess of TBAF, however,further treatment with Amberlyst A-15and its calcium salt as scavengers was needed to purify the reaction mixture.Despite the?nal products being obtained in good yields and the mild resin-cleavage step,this methodology does not seem to introduce any advantage with respect to the use of the more conventional resins.Firstly,the silylated resin is not commercially available and had to be prepared from a1%divinylbenzene–styrene copolymer by lithiation and trapping with chloro(chloromethyl)dimethylsilane,a relatively expensive electrophile.Secondly,the cesium carboxylate had also to be prepared to increase its nucleophilicity in the S N2reaction to attach the resin. Thirdly,a special resin-cleavage protocol was needed, leading to more waste(additional to the excess of reagents) and to the generation of a new silylated resin with no chance of being recycled.

Takahashi et al.recently described the stereoselective synthesis of36peptides containing unnatural amino acids, utilising the Pd(0)-catalysed Mirozoki–Heck reaction of dehydroalanine derivatives in combination with an asym-metric hydrogenation on polymer support.93In this case, the alkene partner was supported on Synphase Rink-amino PS-Crowns e,whereas the aryl iodides were in solution.It was found that4mM Pd(dba)2in MeCN at808C for3h in the presence of TBAC and Et3N were the optimal reaction conditions.Products were obtained with a high purity, except for aryl iodides bearing electron-withdrawing substituents,where a low purity(45–60%,p-AcC6H4I)or no reaction(p-NO2C6H4I)was observed(Scheme18). Asymmetric hydrogenation and?nal cleavage with TFA–CH2Cl2furnished the corresponding

phenylalanine Scheme

16.

Scheme

17.

Scheme18.

F.Alonso et al./Tetrahedron61(2005)11771–1183511783

derivatives with high stereocontrol.Unfortunately,the authors did not give any information about the isolated yields of the ?nal products,making it dif?cult to evaluate the ef?ciency of the whole process.

Portnoy et al.synthesised various poly(aryl benzyl ether)dendrimers on a solid support,based on the initial immobilisation of commercially available 5-hydroxy-isophthalate onto the Wang resin,followed by ester reduction.Repetitive Mitsunobu coupling and ester reduction led to the formation of a second and third-generation of dendrimers.94The three resins were subjected to Mitsunobu reaction with p -iodophenol,followed by Heck coupling with methyl acrylate,with complete conversions being achieved for every resin.Only moderate yields and fair purities were,however,obtained for any of the resins tested upon TFA-induced cleavage (Scheme 19).In fact,this methodology has no advantage with respect to that developed by Hanessian et al.95in which the aryl iodide was directly attached to the Wang resin.In this case,the free cinnamic ester was obtained in 90%overall yield under the same reaction conditions,but minimising the number of steps and consequently,the generation of waste,making the process more economic and time saving.

In a study on indole synthesis,Kondo et al.described the palladium-catalysed intramolecular cyclisation of enamino-esters in the solution phase and on solid supports.96In the solution phase,the expected ethyl 3-phenyl-2-indole-carboxylate was obtained in 56%yield after treatment with a catalytic amount of Pd 2(dba)3,(o -Tol)3P and Et 3N in DMF at 1208C for 2h (Scheme 20).The polymer-supported version of this reaction involved the attachment of the substrate to a hydroxymethyl-polystyrene resin,treatment with the same catalytic system at 1108C for 12h,and ?nal transesteri?cation of the resulting polymer-bound indole carboxylate using NaOMe in MeOH–THF.In this case,the product was obtained in 48%yield after further puri?cation by column chromatography.It seems clear that the solution-phase reaction is advantageous,since it reduces the reaction time in the intramolecular coupling,less steps are used,and the yield is slightly improved.Similar solid-phase indole synthetic strategies have been published recently by the same research group.97

It is clear that the main reason for immobilising a molecule on a solid support for the Heck or any other reaction relies on the simple separation of the intermediates and,?nally,of the products from the reagents and soluble by-products.This fact,which represents a major advantage,compared to the solution-phase chemistry,may hide some inherent incon-veniences and limitations that can curtail the whole ef?ciency of the process,for example,(a)reactions can be driven to completion in most cases,but only in return for consuming an excess of reagent,(b)suitable,robust and versatile linkers are required,which have to be cleaved selectively under mild reaction conditions without destroy-ing the product,(c)a second functionality in the starting material is normally necessary for attachment to the support,as exempli?ed by the intermolecular Heck reaction,in which the polymer-bound aryl iodides must bear an additional group (carboxy,hydroxy,amino,etc.)that remains at the end in the product,whereas most of the polymer-bound alkenes studied are derived from a ,b -unsaturated carboxylic acid derivatives,(d)the selection of usable solvents and the temperature range can be quite restricted (1008C is at the upper limit),(e)the chemistry involving heterogeneous catalysts such as palladium on charcoal is incompatible with solid-phase synthesis methods,(f)the dif?culty of analysing the outcome of a given reaction makes it necessary for the cleavage of the products from the support to be analysed by normal methods and (g)in the case of solid-phase combinatorial chemistry,additional investment is essential for laboratory automation,robotics and mechanical and tag-reading/sorting devices enabling the simultaneous performance of multiple tasks.In short,there is a need for more solid-phase methodology,including the development of traceless

linkers.

Scheme

19.

Scheme 20.

F.Alonso et al./Tetrahedron 61(2005)11771–11835

11784

5.Catalytic systems

The selection of a proper catalytic system is fundamental for achieving the best ef?ciency in a given Heck reaction.In order to design such an ef?cient catalytic system,however, we have to focus not only on its catalytic activity or selectivity,but also on other important topical issues,such as the possibility of recovery of the components,or their toxicity and environmental impact,especially for appli-cation to an industrial scale.In fact,industrial applications

are rare,because the cheap aryl chlorides or many readily available bromides do not react with suf?ciently high yields, turnover numbers and selectivities,even in the presence of the traditional phosphane catalysts.98Signi?cant efforts have been made in recent years to develop more ef?cient catalytic systems,trying to simplify these reactions as much as possible.

5.1.Ligands:ligand-free catalytic systems

Tertiary phosphane ligands have traditionally been used to ensure catalyst stability,in spite of the fact that they can have some detrimental effect on the rate of the individual steps of the coupling reaction.The use of phosphorus ligands in?ne-chemical and industrial processes,however, is less desirable.They are usually toxic,unrecoverable and frequently hamper the isolation and puri?cation of the desired product,as well as the performance of consecutive catalytic steps of the total synthesis.In spite of the fact that numerous phosphane-free ligand systems have been developed,including palladacycles,nucleophilic carbene ligands and others,99these catalytic systems suffer from some drawbacks.The high ligand sensitivity to air and moisture,their tedious multistep synthesis,the high cost of the ligands and the use of various additives curtails their applications.On the other hand,the ligand-free Heck catalytic systems have very recently emerged as more advantageous at all levels,operationally,economically and environmentally.100

We have described in Section4.1a series of methodologies involving the use of alternative arylating agents to aryl halides in the Heck reaction,most of which have a common and advantageous feature,that is,no ligand was added to the reaction mixture.The ligandless approach to carbon–carbon coupling was,however,pioneered independently by Beletskaya101and Jeffery.102The latter author reported,in 1984,the palladium-catalysed vinylation of organic iodides under solid–liquid phase-transfer conditions at,or near, room temperature,using TBAC as the phase-transfer agent and sodium hydrogen carbonate as a base in the absence of any ligand.102a The reactions proceeded with excellent yields(85–98%)and with high regio-and stereoselectivity. Aryl iodides furnished the(E)-products exclusively (Scheme21),whereas(E)-1-iodohexen-1-ene gave a1:15 diastereomeric mixture in favour of the(E,E)-product.The mild conditions allowed this type of reaction to be generalised to thermally unstable vinylic substrates such as methyl vinyl ketone or acrolein.Fortunately,the vinylation of vinylic iodides was greatly accelerated (1–5h)by using potassium carbonate instead of sodium hydrogen carbonate as the inorganic base,with a parallel improvement of the stereoselectivity.102b More recently,a slightly modi?ed catalytic system was applied by Crisp et al.to the Heck coupling of the chiral non-activated alkenes,2-aminobut-3-en-1-ols,with cyclo-hexenyl tri?ate.103In this case,tetra-n-butylammonium tri?ate was used instead of TBAC under mild reaction conditions,the produced dienes being isolated in moderate to good yields and with little or no racemisation (Scheme22).The high reactivity observed with tetra-n-butylammonium tri?ate was attributed to the high rate of dissociation of the tri?ate anion from the neutral palladium(II) intermediate and the formation of a very reactive cationic palladium species.Some bene?cial in?uence was observed when a small amount of water(5equiv)was added to the reaction mixture.Little can be said about the scope of this reaction,since cyclohexenyl tri?ate was the only tri?ate tested.

A very simple catalytic system was used by Gundersen et al. in the coupling of vinylpurine with a variety of aryl iodides (Scheme23).104Better results were obtained when Pd(OAc)2alone was employed as the catalyst compared with catalysts containing phosphane ligands such as triphenylphosphane.All the couplings were highly stereo-selective,including the coupling of vinylpurine with(E)-methyl

3-iodo-2-methylacrylate.

Scheme

21.

Scheme

22.

Scheme23.

F.Alonso et al./Tetrahedron61(2005)11771–1183511785

Buchwald et al.introduced the bulky amine base,methyl(dicyclohexyl)amine,into a phosphane-free catalytic system that found application in the coupling of aryl iodides and bromides with 1,1-and 1,2-disubstituted ole?ns to give trisubstituted ole?ns (Scheme 24).105The method was applicable to the coupling of both electron-de?cient and electron-rich substrates and displayed good stereoselectivity and a high degree of functional-group compatibility.A combination of the bulky amine and tetraethylammonium chloride (TEAC)made the reaction faster and increased the E /Z selectivity,in comparison with other amines.

Reetz et al.discovered that Pd(OAc)2in the presence of the additive,N ,N -dimethylglycine (DMG),is a simple,reactive and selective catalytic system for the Heck reaction of aryl bromides with ole?ns.106The reaction of bromobenzene and styrene in NMP took place with O 95%trans-selectivity with only traces of side products in the presence of a 20:1DMG/Pd ratio (Scheme 25).It had been interesting to know the isolated yields instead of the conversions,as well as the experimental procedure for the product puri?cation,above all taking into account the presence of the additive DMG and the high boiling point solvent NMP.

Another simple catalytic system recently developed by Schmidt et al.was found to catalyse the reaction of bromoarenes with styrene in air in the absence of any ligands.107Conversions of around 95%were achieved by the use of 0.04–1.6mol%PdCl 2,18%HCO 2Na and 112%NaOAc in DMF after 10min at 1408C or 180min at 1008C (Scheme 26).The presence of sodium formate as a reducing agent accelerated the reaction,although it had no effect on the yield of stilbene.It was corroborated that colloidal palladium particles formed in the course of the reaction are the main reservoir of catalytically active homogeneous Pd(0)complexes.The low catalyst loading,the availability and the low prices of the components of the catalytic system,together with the absence of an inert atmosphere,

makes this methodology attractive to be applied at a larger scale.The 6-fold excess of bromoarene required is,however,an important limitation,above all taking into account that bromoarenes are rather expensive and that an additional recycling strategy should be developed for better process ef?ciency.In our opinion,this work demands further study on the applicability to some other aryl bromides and alkenes,as well as a study on the compatibility of different functional groups attached to the substrates with the reaction conditions.

In this context,Pd(OAc)2in combination with K 3PO 4in DMA exhibited a high catalytic activity for the Heck reaction of both activated and deactivated aryl bromides in the absence of any stabilising ligands or additives.108Styrenes and vinylcyclohexene led to the expected coupling products with good to excellent isolated yields (63–98%)when the reaction was performed at 1408C for about 20h (Scheme 27).It is,however,surprising that the more activated terminal ole?ns such as n -butyl acrylate gave low yields.

The group of de Vries has recently concentrated much effort in developing ligand-free palladium catalytic systems for Heck reactions,for example,they reported a practical and cost-effective coupling methodology based on the recovery and re-use of the palladium catalyst,109with different Heck reaction mixtures being separated from precipitated palladium on Celite by ?ltration.The addition of 2equiv of iodine or bromine in NMP dissolved the recovered palladium and allowed the performance of eight successive runs without signi?cant loss of activity.This re-activated palladium catalyst,which is homogenous in character,was suggested to exist as a mononuclear anionic species,although the presence of nanoparticles was not excluded.The same research group proved that the catalytic system reported by Reetz et al.106(see Scheme 25)could work nicely in the absence of the additive DMG and with a lower catalyst loading.A broad range of aryl bromides was reacted with both electron-de?cient and electron-rich ole?ns in the presence of 0.05mol%Pd(OAc)2,and 2.4mmol of NaOAc in NMP at 1358C for 1–15h,affording the products in 80–100%conversion.110The fact that this method was scaled up to a few Kg,together with the low cost of the

catalytic

Scheme

24.

Scheme

25.

Scheme

26.

Scheme 27.

F.Alonso et al./Tetrahedron 61(2005)11771–11835

11786

system,the relatively low solvent volume used and the easy workup procedure,makes it very attractive for large-scale production.

As an example of a speci?c application,a ligand-free palladium-catalysed Heck reaction of methyl2-acetamido-acrylate and aryl bromides was used by de Vries et al.as the key step in the synthesis of enantiopure substituted phenylalanines.111All reactions were performed in NMP at1258C in the presence of Pd(OAc)2,BnNEt3Br and Pr2i NEt or NaOAc as base.A variety of aryl bromides with different electronic character was tested,giving rise to the corresponding products,puri?ed by simple crystallisation, in moderate yields(Scheme28).It is noteworthy that one of the reactions took place in55%yield,even in the absence of the tetraalkylammonium salt,simplifying the catalytic system even more.

The absence of any ligand in the reaction medium, especially phosphane ligands,is very desirable.This absence,however,normally implies the presence of other additives to stabilise the in situ generated palladium species, which nonetheless can be removed more easily.At any rate, more efforts are needed for the ligand-free Heck reaction in order to decrease the reaction temperature,above all in the coupling of aryl bromides.

5.2.Catalysts:supported catalysts