MEPC+60-4-5

For reasons of economy, this document is printed in a limited number. Delegates are

kindly asked to bring their copies to meetings and not to request additional copies.

INTERNATIONAL MARITIME ORGANIZATION

IMO

E

MARINE ENVIRONMENT PROTECTION

COMMITTEE

60th session

Agenda item 4

MEPC 60/4/5 18 December 2009 Original: ENGLISH PREVENTION OF AIR POLLUTION FROM SHIPS

Report on the trials on the verification of the Energy Efficiency Design Index (EEDI)

Submitted by Japan

SUMMARY

Executive summary:

This document provides a report on the EEDI verification trials conducted for two actual ships in accordance with the Interim Guidelines on Voluntary Verification of the Energy Efficiency Design Index. It also identified, based on the trial results, the issues in the Interim Guidelines that need further consideration and improvement, and provided insights on those issues, including suggestions on possible amendments to the Interim Guidelines Strategic direction: 7.3 High-level action: 7.3.1 Planned output: 7.3.1.3 Action to be taken: Paragraph 30 Related documents:

MEPC.1/Circ.682, MEPC.1/Circ.681; MEPC 59/4/2 and GHG-WG 2/2/16 Introduction

1 The MEPC 59 agreed to circulate the Interim Guidelines on Voluntary Verification of the

Energy Efficiency Design Index (MEPC.1/Circ.682: “the Verification Guidelines” or just “the

Guidelines”, hereafter) for the purpose of conducting EEDI verification trials on a voluntary

basis. By the time of implementation of the mandatory EEDI scheme, the Verification Guidelines are to be appropriately revised and adopted as “Guidelines on Surveys and Certification”. As part of this process, conducting EEDI verifications on a trial basis is a very

important step for identifying necessary improvements to be made to the Guidelines and makes it

possible to propose relevant revisions of the Guidelines. A major aim of these EEDI verification

trials is to develop a method capable of ensuring fair and robust verifications. At the same time,

careful attention should be paid to not imposing too much burden on shipbuilders and other

stakeholders by introducing an impracticable verification method. To achieve this, EEDI verification trials for two actual ships were conducted by a designated verifier (Class NK) in

close coordination with the Ministry of Land, Infrastructure, Transport and Tourism (MLIT),

Japan.

MEPC 60/4/5

- 2 -

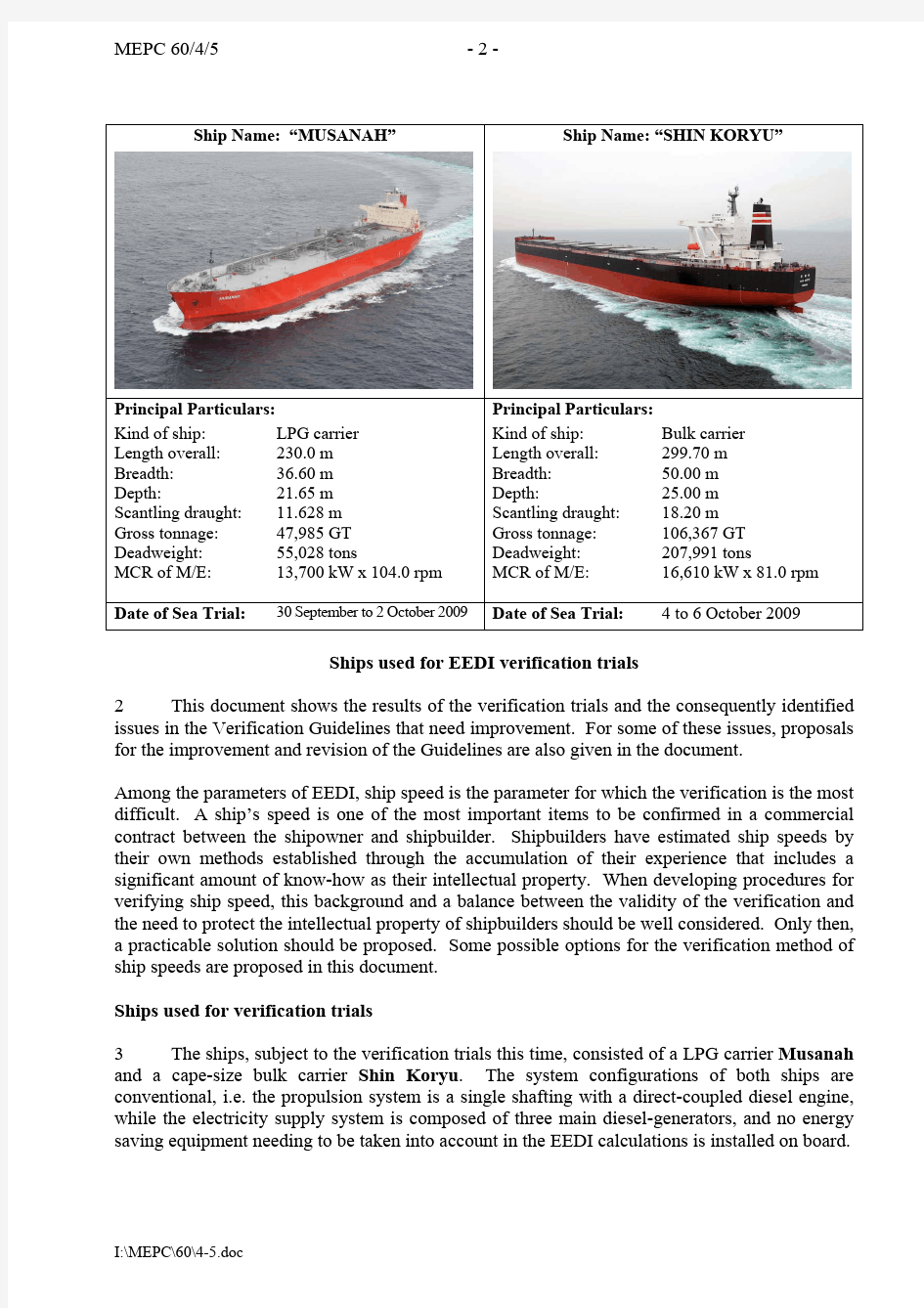

Ship Name: “MUSANAH”

Ship Name: “SHIN KORYU”

Principal Particulars:

Principal Particulars:

Kind of ship:

Length overall:

Breadth:

Depth:

Scantling draught:

Gross tonnage:

Deadweight:

MCR of M/E:

LPG carrier 230.0 m 36.60 m 21.65 m 11.628 m 47,985 GT 55,028 tons 13,700 kW x 104.0 rpm Kind of ship: Length overall: Breadth: Depth: Scantling draught: Gross tonnage: Deadweight: MCR of M/E: Bulk carrier 299.70 m 50.00 m 25.00 m 18.20 m 106,367 GT 207,991 tons 16,610 kW x 81.0 rpm Date of Sea Trial: 30 September to 2 October 2009 Date of Sea Trial: 4 to 6 October 2009

Ships used for EEDI verification trials

2 This document shows the results of the verification trials and the consequently identified

issues in the Verification Guidelines that need improvement. For some of these issues, proposals

for the improvement and revision of the Guidelines are also given in the document.

Among the parameters of EEDI, ship speed is the parameter for which the verification is the most

difficult. A ship’s speed is one of the most important items to be confirmed in a commercial

contract between the shipowner and shipbuilder. Shipbuilders have estimated ship speeds by

their own methods established through the accumulation of their experience that includes a

significant amount of know-how as their intellectual property. When developing procedures for

verifying ship speed, this background and a balance between the validity of the verification and

the need to protect the intellectual property of shipbuilders should be well considered. Only then,

a practicable solution should be proposed. Some possible options for the verification method of

ship speeds are proposed in this document.

Ships used for verification trials

3 The ships, subject to the verification trials this time, consisted of a LPG carrier Musanah

and a cape-size bulk carrier Shin Koryu . The system configurations of both ships are conventional, i.e. the propulsion system is a single shafting with a direct-coupled diesel engine,

while the electricity supply system is composed of three main diesel-generators, and no energy

saving equipment needing to be taken into account in the EEDI calculations is installed on board.

- 3 - MEPC 60/4/5

Summary of verification trials

4 The verification trials were conducted basically in accordance with the Verification

Guidelines, of which procedures are illustrated in Figure 1 below.

*

To be conducted by a test organization or a shipbuilder itself.

Figure 1: Basic Flow of Verification Process (MEPC.1/Circ.682)

5 Preliminary verification at the design stage:

.1 Preparation of EEDI Technical File and Additional Information: The EEDI

Technical File and Additional Information were developed by the shipbuilders

based on the results of tank tests (model tests) formerly conducted for the subject

ships. Regarding tank tests, paragraph 4.2.5 of the Verification Guidelines reads

“… based on reliable results of tank test”. Although there might be some room

for discussion about the criteria for determining reliability, the results of the tank

tests were accepted as they were by the verifier, just by checking the particulars of

the tank test facilities and the calibration records of the measuring equipment

used; and

.2 Verification of the Attained EEDI: The calculation process of the Attained EEDI

was verified by the verifier based on the information provided in the

EEDI Technical Files and Additional Information. Regarding the methods used to

estimate the power curves (relationship between ship speed and shaft power

of M/E), it was confirmed by the verifier that the power curves under the

fully-loaded condition and the sea trial condition had been estimated in

accordance with exactly the same procedures. However, the shipbuilder’s

experience-based parameters such as Model-Ship correlation factors used in the

estimation process were accepted as they were, because it is not practicable for

any person or organization other than the shipbuilder to examine the technical

MEPC 60/4/5 - 4 -

aspects of the parameters as described in paragraph 4.2.6 of the Guidelines. It was

also confirmed that the calculations of the Attained EEDI were done in

accordance with the EEDI Calculation Guidelines (MEPC.1/Circ.681).

6 Final verification during sea trials:

.1 Sea trials were carried out in accordance with the test procedures which had been

prepared by the respective shipbuilders and confirmed by the verifier. For both

ships, the sea trials were carried out under the ballast condition, not the

fully-loaded condition. During the sea trials, the ship condition (draft and trim),

the system configurations of each ship stated in the EEDI Technical Files and the

measured values needed for development of the power curves were confirmed by

the verifier; and

.2 Final verification of the Attained EEDI: A power curve under measured sea

conditions was developed by the respective shipbuilders. From the power curve,

the ship speed at 75% MCR was determined and the Attained EEDI was

calculated by each shipbuilder. It was confirmed by the verifier that the

calculations of the power curve development was in accordance with ISO 15016

or the equivalent by fully following the shipbuilder’s calculations. It was also

confirmed that the ship speed needed for EEDI calculations were determined

appropriately in accordance with the Verification Guidelines.

Preliminary verification at the design stage

7 Items that should be included in the EEDI Technical File are listed in paragraph 4.2.2 of

the Verification Guidelines. The items included in the EEDI Technical Files of the verification

trials and their explanations are summarized in Table 1.

A sample of an EEDI Technical File developed through the verification trials is provided in the

annex of this document.

Table 1 – Items included in EEDI Technical File

Items Explanations

1 Deadweight, shaft power of the main

and auxiliary engines, ship speed, and

SFC of the main and auxiliary engines.

Value of each item should be provided.

A copy of NO x Technical Files showing SFC of

the main and auxiliary engines should be

attached.

2 Power curves under fully-loaded

condition and sea trial condition

Power curves should be illustrated.

3 Principal particulars and the overview

of propulsion and electricity supply

system

For easy reference of system configurations, a

schematic figure of systems should be illustrated.

- 5 - MEPC 60/4/5

4 Estimation process and methodology of

the power curves at design stage

A flow chart of estimation process of power

curves at design stage should be illustrated.

Descriptions of concrete values of parameters are

not necessary.

5 Description of energy saving equipment Specifications, schematic figures and/or photos, etc., of the following energy saving equipment should be provided, respectively:

- Energy saving equipment to be taken into account of in the EEDI calculations

- Other Energy saving equipment Alternatively, attachment of commercial catalogues may be acceptable.

6 Calculated value of the Attained EEDI Attained EEDI calculated in accordance with the EEDI Calculation Guidelines with its calculation summary should be provided.

8 Items that should be included under Additional Information are listed in paragraph 4.2.7

of the Verification Guidelines. The items included in the Additional Information of the

verification trials and their explanations are summarized in Table 2.

“Additional Information” is information which is not included in the EEDI Technical File and

that the verifier should request the shipbuilder to provide directly to the verifier. Additional

Information generally includes confidential information of the shipbuilder. From the viewpoint

of intellectual property protection, it is already specified in the Verification Guidelines that the

verifier should return the information to the shipbuilder when so requested. However, in addition

to this, it seems necessary that a secrecy agreement clause should be also specified in the Guidelines. A proposal for a revision of the Guidelines to this effect will be given in

paragraph 23 below.

Table 2 – Items included in Additional Information

Items Explanations

1 Description of the tank test facility The items are for examination of quality of tank tests. The items should include, at a minimum, the name of tank test facility, particulars of the tank and towing equipment, and calibration records of the measuring equipment used.

2 Lines of both the model ship and

the actual ship

The items are for use in confirming the similarity

between the model ship and actual ship.

3 The lightweight of the ship and

displacement table

The items are for confirmation of deadweight of the

ship.

4 Detailed report on the tank tests

5 Detailed calculation process of the

power curves

The items are for confirming that the power curves

under the fully-loaded condition and sea trial

condition are estimated in accordance with exactly

the same procedures.

The items should include sufficient information for a

verifier to fully follow an estimation process of power

curves, i.e. uncorrected measured data of tank tests,

shipbuilder’s experience-based parameters, propeller

open characteristics, and detailed calculation process

which can be easily followed should be included.

MEPC 60/4/5 - 6 -

9 The calculation process used for the Attained EEDI was verified based on the information provided in the EEDI Technical File and Additional Information. The following two points were confirmed during the verification process:

.1 The power curves under the fully-loaded condition and sea trial condition had been estimated in accordance with exactly the same procedures. This

confirmation was done in order to prevent the possibility that the power curve

under the sea trial condition is intentionally estimated in a conservative manner

(slow-speed side) relative to that under the fully-loaded condition so as to obtain a

lower value for the Attained EEDI; and

.2 The Attained EEDI was calculated taking into account all the necessary elements for EEDI, in accordance with the EEDI Calculation Guidelines

(MEPC.1/Circ.681).

When verifying the estimated power curves, as mentioned above, the tank test results and the shipbuilder’s experience-based parameters such as Model-Ship correlation factors for the

fully-loaded condition and for the sea trial condition were accepted as they were. However, for

more robust verification, further discussion would be necessary on issues pertaining

to 1) confirmation of the reliability of the tank tests, and 2) verification of the experience-based parameters. At the same time, as mentioned in paragraph 2 above, the historical background of

ship speed estimation and the balance between validity of the verification and intellectual property protection of the shipbuilder should be also considered for a practicable solution. Some possible options for a useful method for verifying ship speeds will be proposed in paragraph 22 below.

Final verification during sea trials

10 Prior to the sea trials, the measurement methods necessary for the measurement items for developing the required power curve were confirmed in the test procedures prepared by the shipbuilder.

11 The ship condition (draft and trim), the system configurations stated in the EEDI Technical File, and the measured values needed for developing a power curve listed in

Table 3 were confirmed onboard each ship. Each item listed in Table 3 is not a kind of newly required item to be measured at the time of a sea trial. However, for each item, a specific measurement method is not necessarily specified in the relevant Rules/Regulations. It may be necessary to develop a standard measurement method for some of these items in the future, which is an open question.

Table 3 – Items Measured and Measurement Methods Used

Measurement Methods

Items

“MUSANAH” “SHIN

KORYU”

Draft, Trim Visual measurement Visual measurement Speed over ground Temporarily installed GPS Temporarily installed GPS

Wind direction/speed Wind indicator of the ship Wind indicator of the ship

Shaft power of M/E Estimation from fuel rack Estimation from fuel consumption

- 7 - MEPC 60/4/5 12 Paragraph 4.3.7 of the Verification Guidelines specify that a power curve based on a measured ship speed should be calibrated by taking into account the sea condition in accordance with ISO 15016:2002 or the equivalent. It was verified that the calibration was in accordance with ISO 15016:2002 or the equivalent, by fully following the calculation process for the calibration. Considering the ship’s schedule, the verification was to be completed in a very short period of time, such as one or two weeks between the sea trial and delivery of the ship. In cases where a calibration was conducted in accordance with a method other than the ISO 15016:2002, it is not practicable to verify the equivalency of the method to ISO 15016:2002 in such a very short period. Therefore, it seems reasonable that calibrations of power curves should be fully in accordance with a standard method such as ISO 15016:2002, and the calibration calculations should be done using standard calculation software like the one proposed by Korea at MEPC 59 (MEPC 59/4/39).

13 It was confirmed that the finally attained EEDI was calculated using the results of the speed trial in accordance with the Verification Guidelines. In the verification trials, the ship speed under the fully-loaded condition was determined using the method illustrated in Figure 2 of the Guidelines.

Issues that need further consideration and improvement in the Verification Guidelines and some insights on them

14 Issues for further consideration and proposals for improvement of the Verification Guidelines found in the course of conducting the verification trials are given in the following paragraphs.

15 Definitions of “Ship of the same type” and “Ship of a similar type” (paragraphs 2.2 and 2.3 of the Guidelines): To clarify the application criteria for omission of tank tests, the definition of the terms “Ship of the same type” and “Ship of a similar type” should be clarified further, by investigating shipbuilders’ current criteria for omitting tank tests.

16 Definition of “Tank tests” (paragraph 2.4 of the Guidelines): In cases where a sea trial under the fully-loaded condition is not practicable, the ship speed needed for EEDI calculation is determined by comparing estimated power curves under the fully-loaded condition and the sea trial condition, using the actual ship speed measured during sea trials. Therefore, both power curves are to be estimated at the design stage with the same accuracy in accordance with exactly the same procedures. For that reason, the Verification Guidelines specify that, in principle, power curves under both conditions should be estimated based on reliable results of tank tests. In paragraph 2.4 of the Guidelines, use of numerical tests is also allowed for estimating power curves. For numerical tests, however, further clarification would be necessary with respect to their definition and applicable range. The following cases are expected as examples of applying various kinds of numerical tests, e.g., theoretical calculations, CFD, or use of charts, etc., for estimating power curves under current shipbuilder practices.

.1 Substitution for a tank test;

.2 Supporting use for tank tests like calibration of tank test results, e.g., evaluation of the effect of additional hull features such as fins, etc., on ship’s performance;

and

.3 Estimation of propeller open characteristics.

MEPC 60/4/5 - 8 -

As mentioned above, estimation of power curves should be based on reliable tank test results, in principle. Therefore, use of a numerical test as a substitution for a tank test should not be readily accepted. On the other hand, for the cases of subparagraphs 16.2 and 16.3 above, establishment of a framework for accepting such cases that seem to be practicable requires further discussion.

17 Language of EEDI Technical File (paragraph 4.2.2 of the Guidelines): Considering that the targets of EEDI verifications include ships engaged in international voyages, the EEDI Technical File should be written at least in English. Therefore, an amendment to paragraph 4.2.2 of the Verification Guidelines is proposed as follows:

4.2.2 EEDI Technical File, which is to be developed by either a shipowner or a

shipbuilder, should be written at least in English. EEDI Technical File should include at least but not limited to:

…

18 Contents of EEDI Technical File (paragraph 4.2.2.6 of the Guidelines): The Verification Guidelines require that the calculated value of the Attained EEDI be included in the EEDI Technical File. However, the EEDI Technical File should include not only the calculated value but also the calculation summary. The calculation summary should include at least each value of the calculation parameters and a description of the calculation process used to determine the Attained EEDI. Therefore, an amendment to paragraph 4.2.2.6 of the Verification Guidelines is proposed as follows:

4.2.2.6 Calculated value of the Attained EEDI with the calculation summary, which

should contain, at a minimum, each value of the calculation parameters and the calculation process used to determine the Attained EEDI.

19 SFC of diesel engines (paragraph 4.2.4 of the Guidelines): The SFCs of main and auxiliary engines are quoted from the respective NO x Technical Files. However, since the SFC in the NO x Technical File is an uncorrected measured value, for EEDI calculations, the SFC should be corrected to a value corresponding to ISO standard reference conditions (Total barometric pressure: 100 kPa, Air temperature: 298 K, Relative humidity: 30%, Charge air coolant temperature: 298 K) using the standard lower calorific value of the fuel oil (42,700 kJ/kg) referring to ISO 15550:2002 and ISO 3046-1:2002. Therefore, an amendment to the first sentence of paragraph 4.2.4 of the Verification Guidelines is proposed as follows:

4.2.4 The SFC of the main and auxiliary engines should be quoted from the approved

NO x Technical File and should be corrected to the value corresponding to the ISO standard reference conditions using the standard lower calorific value of the fuel oil (42,700 kJ/kg), referring to ISO 15550:2002 and ISO 3046-1:2002.

reliability

of tank tests (paragraph 4.2.5 of the Guidelines): As mentioned in for

20 Criteria

paragraph 9 above, the criteria used for determining the reliability of tank tests are still open to question. For ensuring the quality of tank tests, for example, approval of tank test organizations or witnessing of each tank test by a verifier may be necessary in the future.

- 9 - MEPC 60/4/5 21Requirement of tank tests (paragraph 4.2.5 of the Guidelines): Although the verification Guidelines specify that estimation of power curves should be based on tank tests, in principle, the requirement of tank tests should be carefully discussed further, for the following reasons:

.1 In cases where the requirements of tank tests are applied to every ship of 400 GT or above for which EEDI Calculation Guidelines (MEPC.1/Circ.681) are applied,

there is a possibility that the number of tank test facilities will be insufficient to

adequately meet the demand for conducting such tests; and

.2 It is supposed that a large number of small shipbuilders will not have the experience required for properly conducting tank tests. Such shipbuilders may

be confronted with too many difficulties when tank tests are required for their

ships.

For mandatory EEDI scheme in the future, a categorization of ships according to their size is supposed to be introduced. It should be noted that the issue of the EEDI implementation in relation to ship size category was discussed at GHG-WG 2, based on the proposal by Japan (GHG-WG 2/2/16). GHG-WG 2 “agreed, in principle, to the categorization of ship sizes as proposed by Japan in document GHG-WG 2/2/16, annex 3, with a change from [10,000] to [X].” (paragraph 2.8 of MEPC 59/4/2 “Report on the outcome of second Intersessional Meeting of the Working Group on GHG Emissions from Ships”). Such “in-principle agreed” size categorization was as follows: Category I (less than 400GT: the whole EEDI requirements are exempted), Category II (400 to [X]GT: EEDI calculation is required, while compliance with EEDI limit is exempted), and Category III ([X]GT or above: both EEDI calculation and compliance with the limit are required). If such a categorization is applied, one idea for a solution of the above concerns is exempting tank tests for Category II ships for which compliance with the limit value of EEDI is not mandatory. In addition, for ships for which a sea trial under the fully-loaded condition is conducted, omission of tank tests seems to be technically acceptable as the ship speed for EEDI calculation could be confirmed from the results of speed trials directly.

22 Verification method of ship speed (paragraph 4.2.6 of the Guidelines): Bearing in mind that it is not practicable for some kinds of ships to undergo sea trials under the fully-loaded condition, some possible alternative options for methods for verifying ship speeds are proposed. The concepts of these options with their respective advantages and disadvantages are summarized in Table 4. For the verification trials this time, Option A was adopted as the method used to verify ship speeds. However, as pointed in paragraph 9, the difficulties of verifying the shipbuilder’s experience-based parameters such as Model-Ship correlation factors still remained unsolved. In general, because different values are used as the experience-based parameters for the fully-loaded condition and for the sea trial condition (ballast condition), it is not practicable to confirm the validity of the experience-based parameters for the fully-loaded condition through conducting the sea trial under the ballast condition. Option B, a modified method of Option A, would make it possible to indirectly verify a ship’s speed under the fully-loaded condition through a verification of the ship’s speed under the sea trial condition. This could be achieved by setting some restrictions on experience-based parameters. These restrictions could consist of a kind of giving correlations between experience-based parameters for the fully-loaded condition and for the sea trial condition. Other possible options are also listed in Table 4 for further discussion.

MEPC 60/4/5 - 10 -

Table 4 – Options for Methods to Verify Ship Speeds

Explanation Advantages

Disadvantages

A Shipbuilders’ own methods for estimating

power curves are accepted as they are. It is

confirmed that power curves under

fully-loaded condition and sea trial

condition have been estimated in

accordance with exactly the same

procedures by following the calculations

used for the respective estimations.

During the confirmation process,

shipbuilders’ experience-based parameters

such as Model-Ship correlation factors used

in the calculations are accepted as they are,

because it is not practicable for verifiers to

examine the technical aspects of the

parameters.

- Shipbuilders are able

to use their own

procedures.

- Relatively accurate

estimation of power

curves are expected

(as has been the case

until now).

- Burden of

verification is large,

because verifiers

need to follow the

various procedures

used by

shipbuilders one by

one.

- Less robustness of

verification of

power curves.

B Option B is a modified version of Option A.

The difference between these options is that

some restrictions are set on

experience-based parameters in Option B,

which enable verifiers to indirectly verify

power curves under fully-loaded condition

through a speed trial.

The restrictions give correlations between

experience-based parameters for

fully-loaded condition and sea trial

condition. For example, the following may

be assumed as reasonable ideas for setting

such restrictions:

1) Use same values for experience-based

parameters for both fully-loaded condition

and sea trial condition.

2) Shipbuilders’ own experience-based

parameters for sea trial condition multiplied

by a ratio between the evaluated values of

the parameters for both conditions using

evaluation formulas developed by the

Organization are used to estimate power

curves under fully-loaded condition.

- Shipbuilders are able

to use their own

procedures.

- Relatively accurate

estimation of power

curves are expected

(less accurate

compared to

Option A).

- Power curves are

verifiable by

verifiers.

- Burden of

verification is large,

because verifiers

need to follow the

various procedures

used by

shipbuilders one by

one.

- 11 - MEPC 60/4/5

C Tank test processes and the estimation of

power curves are left to the discretion of

shipbuilders. Estimated power curves are

accepted by verifiers as they are, based on

the declarations made by shipbuilders.

Verifiers confirm that the Attained EEDI is

calculated in accordance with the EEDI

Calculation Guidelines.

- Shipbuilders are able

to use their own

procedures.

- Relatively accurate

estimation of power

curves are expected

(as has been the case

until now).

- Burden of

verification is small.

- Less robustness of

verification of

power curves.

D A standard method developed by the

Organization is used to estimate power

curves.

All parameters other than measured

parameters used in the estimation process

are determined using standard values or

evaluation formulas developed by the

Organization.

- Burden of

verification is small.

- Power curves are

verifiable by

verifiers.

- Less accuracy of a

ship speed under

fully-loaded

condition leading to

lessened accuracy

of EEDI.

- Shipbuilders may

be forced to

dramatically

change their

procedures.

23 Additional

Information

(paragraph 4.2.8 of the Guidelines): Additional Information includes confidential information of the shipbuilder, in general. As noted in paragraph 8 above, a secrecy agreement clause should be specified in the Verification Guidelines. Therefore, an amendment to paragraph 4.2.8 of the Verification Guidelines is proposed as follows:

4.2.8 Such additional information may contain shipbuilders’ confidential information.

Therefore, after the verification, the verifier should return all or part of such information to the shipbuilder at its request. In the case where the shipbuilder wants a secrecy agreement with the verifier, the additional information should be provided to the verifier upon conclusion of such an agreement.

24 Test procedures for speed trials (paragraph 4.3.1 of the Guidelines): Prior to a sea trial, test procedures for the speed trial, including descriptions of items needing to be measured and corresponding measurement methods, should be submitted to the verifier. Therefore, an amendment to paragraph 4.3.1 of the Verification Guidelines is proposed as follows:

4.3.1 Prior to the sea trial,a shipowner should submit the application for the verification

of EEDI together with a description of test procedure to be used for the speed trial, the final displacement table and the measured lightweight, or a copy of the survey report of deadweight, as well as a copy of NO x Technical File, as necessary. The test procedure should include, at a minimum, descriptions of necessary items to be measured and corresponding measurement methods for developing a power curve under the sea trial condition.

25 Confirmation of measuring accuracy (paragraph 4.3.2 of the Guidelines): At the time of speed trials, it may be necessary for verifiers to confirm the accuracy of the measurements taken, e.g., confirm calibration records of the measurement equipment, etc., which is an open question.

MEPC 60/4/5 - 12 -

26 Method used for measuring shaft power of main engine (paragraph 4.3.6 of the Guidelines): As with the methods used to estimate ship speeds, each shipbuilder uses its own method for measuring the shaft powers of main engines during sea trials. Under the current circumstances, since it is difficult to fix the most appropriate method for measuring the shaft powers of main engines, it seems practicable to accept measuring methods proposed by shipbuilders, unless specific problems are found in the proposed methods. Therefore, an amendment to paragraph 4.3.6 of the Verification Guidelines is proposed as follows:

4.3.6The shaft power of the main engine should be measured by shaft power meter or

estimated by fuel rack. Otherwise, it should be measured by a method which the engine manufacturer recommends. Other methods may be acceptable upon agreement of the shipowner and shipbuilder and with approval of the verifier.

However, for fairer and more robust verifications, further discussions may be necessary regarding methods for measuring a shaft power in the future.

27 Method of calibrating power curve (paragraph 4.3.7 of the Guidelines): As mentioned in paragraph 12, it seems reasonable that calibrations of power curves should be fully in accordance with a standard method such as ISO 15016:2002, and the calibration calculations should be conducted using standard calculation software like the one proposed by Korea at MEPC 59 (MEPC 59/4/39).

28 Verification of power curves developed during sea trials (paragraph 4.3.7 of the Guidelines): Results of a speed trial and a detailed description of the calculation process used in developing the power curve should, upon agreement with the shipowner, be submitted from the shipbuilder to the verifier for verification that the power curve was developed using the measured data in accordance with a standard method such as ISO 15016:2002. Therefore, an amendment to paragraph 4.3.7 of the Verification Guidelines is proposed as follows:

4.3.7 The shipbuilder should develop power curves based on the measured ship speed

and the measured shaft power of the main engine at sea trial. For the development of the power curves, the shipbuilder should calibrate the measured ship speed, if necessary, by taking into account the effects of wind, tide and waves in accordance with ISO 15016:2002 or the equivalent. Upon agreement with the shipowner, the shipbuilder should submit a detailed report of the speed trials and the development of the power curve to the verifier for verification.

deadweight/gross

tonnage (New paragraph 4.3.9 and paragraph 4.3.10 of the 29 Final

Guidelines): In cases where the finally determined deadweight/gross tonnage differs from the designed deadweight/gross tonnage used in the EEDI calculation during the preliminary verification process, the Attained EEDI should be recalculated using the finally determined deadweight/gross tonnage. The recalculated Attained EEDI should be included in the EEDI Technical File. Therefore, it is proposed that a new paragraph 4.3.9 be added to the Guidelines. In this case, the original paragraph numbers 4.3.9 to 4.3.11 are to be renumbered and shifted in order.

New 4.3.9 In cases where the finally determined deadweight/gross tonnage differs from the designed deadweight/gross tonnage used in the EEDI calculation during the preliminary verification, the shipowner or shipbuilder should recalculate the Attained EEDI by using the finally determined deadweight/gross tonnage.

- 13 - MEPC 60/4/5 In addition, an amendment to paragraph 4.3.11 (ex. 4.3.10) of the Verification Guidelines is proposed as follows:

4.3.1011 The shipowner or the shipbuilder should revise an EEDI Technical File, as

necessary, by taking into account the results of sea trials. Such revision should include, as applicable, the adjusted power curve based on the results of sea trial (namely, modified ship speed at 75% of MCR power of the main engine at full-loaded condition), the finally determined deadweight/gross tonnage and SFC described in the approved NO x Technical File, and the recalculated Attained EEDI based on these modifications.

Action requested of the Committee

30 The Committee is invited to consider this document and take action as appropriate.

***

MEPC 60/4/5

ANNEX

EEDI Technical File (Sample)

1. Data

information

1.1 General

Shipbuilder JAPAN Shipbuilding Company

Hull No. 12345

IMO No. 94111XX

Kind of ship Bulk carrier

1.2 Principal

particulars

Length overall 250.0 m

Length between perpendiculars 240.0 m

Breadth, molded 40.0 m

Depth, molded 20.0 m

Scantling draught, molded 14.0m

Deadweight at scantling draught 150,000 tons

engine

1.3 Main

Manufacturer JAPAN Heavy Industries Ltd.

Type 6J70A

Maximum continuous rating (MCR) 15,000 kW x 80 rpm

SFC at 75% MCR 165.0 g/kWh

Number of set 1

engine

1.4 Auxiliary

Manufacturer JAPAN Diesel Ltd.

Type 5J-200

Maximum continuous rating (MCR) 600 kW x 900 rpm

SFC at 50% MCR 220.0 g/kWh

Number of set 3

speed

1.5 Ship

Ship speed in deep water at

14.25 knots

scantling draught at 75% of MCR

MEPC 60/4/5

ANNEX

Page 2

Curves

2. Power

The power curves estimated at the design stage and modified after the speed trials are shown in Figure 2.1.

Figure 2.1: Power curves

MEPC 60/4/5

ANNEX

Page 3 3. Overview of Propulsion System and Electric Power Supply System

system

3.1 Propulsion

3.1.1 Main engine

Refer to subparagraph 1.3.

3.1.2 Propeller

Type Fixed pitch propeller

Diameter 7.0 m

Number of blades 4

Number of set 1

3.2 Electric power supply system

3.2.1 Auxiliary engines

Refer to the subparagraph 1.4.

3.2.2 Main generators

Manufacturer JAPAN Electric

Rated output 560 kW (700 kVA) x 900 rpm

Voltage AC 450 V

Number of set 3

Figure 3.1: Schematic figure of propulsion and electric power supply system

MEPC 60/4/5

ANNEX

Page 4

4. Estimation Process of Power Curves at Design Stage

Power curves are estimated based on model test results. The flow of the estimation process is shown below.

Figure 4.1: Flow chart of process for estimating power curves

5. Description of Energy Saving Equipment

5.1 Energy saving equipment taken into account in EEDI calculation

N/A

5.2 Other energy saving equipment

(Example)

5.2.1 Rudder fins

MEPC 60/4/5

ANNEX

Page 5

5.2.2 Propeller boss cap fins

……

(Specifications, schematic figures and/or photos, etc., for each piece of equipment or device should be indicated. Alternatively, attachment of the commercial catalogue may be acceptable.)

6. Calculated Value of Attained EEDI

6.1 Basic data

Type of Ship Capacity DWT Speed V ref (knots)

Bulk Carrier 150,000 14.25

6.2 Main engine

MCR ME (kW) Shaft Gen. P ME (kW) Type of Fuel

C FME SCF ME (g/kWh) 15,000 N/A 11,250 HFO 3.1144 165.0

6.3 Auxiliary engines

P AE (kW) Type of Fuel C FAE SCF AE (g/kWh)

625 HFO 3.1144 220.0

6.4 Ice class

N/A

6.5 Innovative electrical energy efficient technology

N/A

6.6

Innovative mechanical energy efficient technology N/A

6.7

Calculated value of Attained EEDI

()()()()

mile /ton CO g 905.21

25.1415000010

00.2201144.36250.1651144.311250121)()(1)()(1)(11)()()(1??=×××?+××+×××=???

???? ? ???+?????+ ?? =∑∑∑∏∑∏======w

ref i neff i ME FME i eff i eff AE FAE neff i i AEeff i eff nPTI i i PTI M j j w

ref i AE FAE AE nME i i ME i FME i ME M j j f V Capacity f SFC C P f SFC C P f P f f V Capacity f SFC C P SFC C P f EEDI Attained EEDI: 2.905 g-CO 2/ton mile

________________