AIC1896PG中文资料

1. 4MHz Thin Package

Current-Mode Step-Up DC/DC Converter

Analog Integrations Corporation Si-Soft Research Center

DS-1896G-01 121208

FEATURES

Fixed Frequency 1.4MHz Current-Mode PWM Operation.

Adjustable Output Voltage up to 30V.

Guaranteed 13V/ 200mA Output with 5V Input. 2.5V to 10V Input Range.

Maximum 0.1μA Shutdown Current. Programmable Soft-Start.

Tiny Inductor and Capacitors are allowed.

Space-Saving SOT-23-6 and TSOT-23-6 Package.

APPLICATIONS

White LED Backlight. OLED Driver.

LCD Bias

DESCRIPTION

AIC1896 is a current-mode pulse-width modulation (PWM), step-up DC/DC Converter. The built-in high voltage N-channel MOSFET allows AIC1896 for step-up applications with up to 30V output voltage, as well as for Single Ended Primary Inductance Converter (SEPIC) and other low-side switching DC/DC converter.

The high switching frequency (1.4MHz) allows the use of small external components. The Soft-Start function is programmable with an external capacitor, which sets the input current ramp rate.

The AIC1896 is available in a space-saving SOT-23-6 and TSOT-23-6 package.

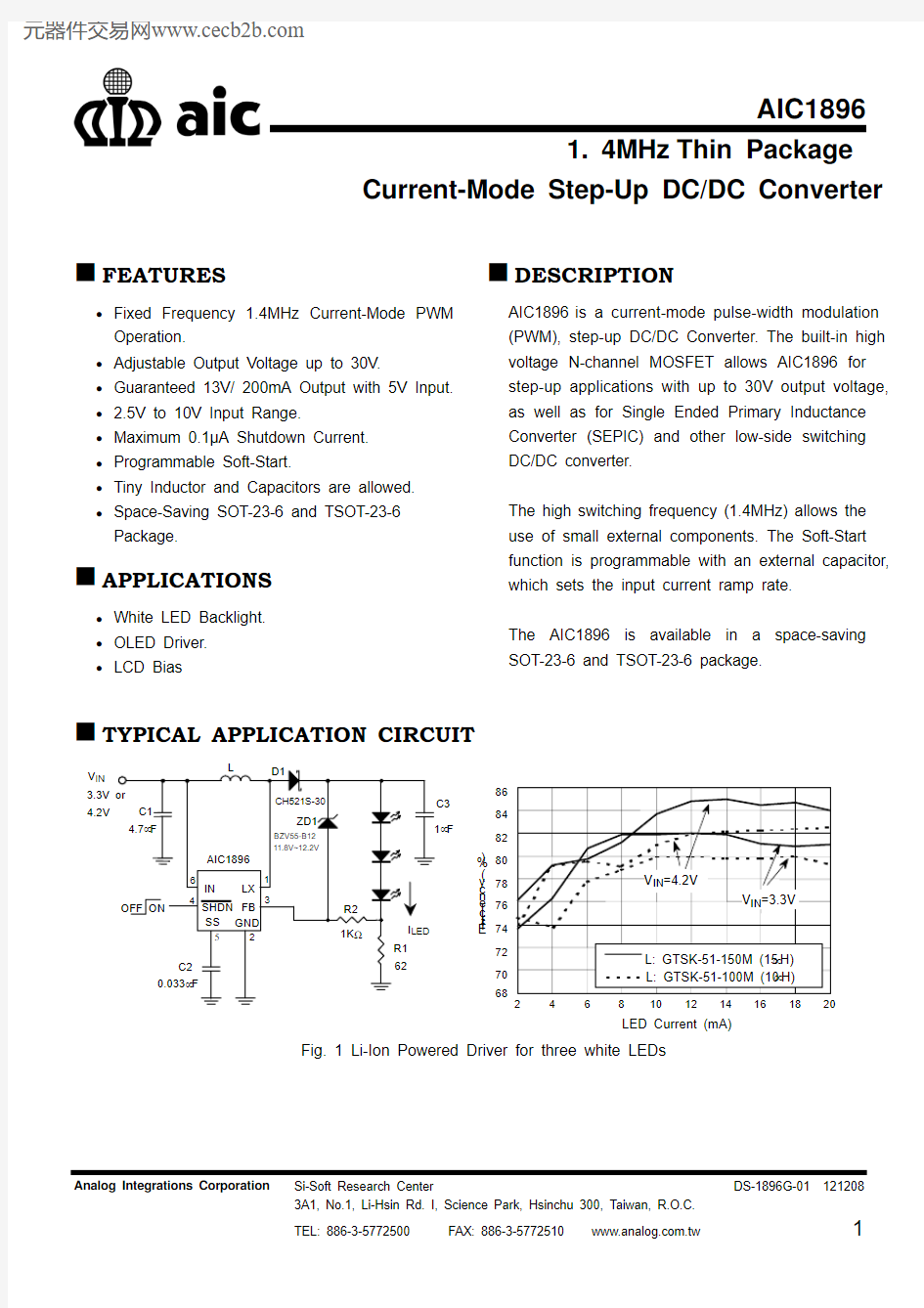

TYPICAL APPLICATION CIRCUIT

μF

V IN

4.2V

687072747678808284

86

2

4

6

8

10

12

14

16

18

20

LED Current (mA)

E f f i c i e n c y (%)

Fig. 1 Li-Ion Powered Driver for three white LEDs

F

V IN

4.2V

LED Current (mA)

E f f i c i e n c y (%)

6062646668707274767880

Fig. 2 Li-Ion Powered Driver for six white LEDs

ORDERING INFORMATION

& Reel Packing Type

AIC1896PGTR

in Lead Free SOT-23-6 Package & Tape

& Reel Packing Type

TSOT-23-6 Marking

Part No. Marking AIC1896PK 896PK AIC1896GK

896GK

SOT-23-6 Marking

Part No. Marking AIC1896PG 1896P AIC1896GG

1896G

ABSOLUTE MAXIMUM RATINGS

LX to GND -0.3V to +33V FB to GND -0.3V to +6V IN, SHDN-0.3V to +11V SS to GND -0.3V to +6V LX Pin RMS Current 0.6A Continuous Power Dissipation 727mW Operating Temperature Range -40°C to 85°C Junction Temperature 125°C Storage Temperature Range -65°C to 150°C Lead Temperature (soldering, 10s) 260°C

Absolute Maximum Ratings are those values beyond which the life of a device may be impaired. TEST CIRCUIT

V IN V OUT

10μ

ELECTRICAL CHARACTERISTICS

SHDN

Note 1: Specifications are production tested at T A=25°C. Specifications over the -40°C to 85°C operating temperature range are assured by design, characterization and correlation with Statistical Quality

Controls (SQC).

TYPICAL PERFORMANCE CHARACTERISTICS

Fig. 3 Switching Frequency vs. Temperature

S w i t c h i n g F r e q u e n c y (M H z )

Temperature (°C)

Fig. 4 Frequency vs. Supply Voltage

F r e q u e n c y (M H z )

Supply Voltage (V)

Supply Voltage (V)

Fig. 5 R DSON vs. Supply Voltage

R D S (O N ) (?)

Output Current (mA)

Fig. 6 Load Regulation (L1=10μH)

O u t p u t V o l t a g e (V )

Output Current (mA)

Fig. 7 Load Regulation (L1=22μH)

O u t p u t V o l t a g e (V )

Supply Voltage (V)

Fig. 8 Switching Current

S u p p l y C u r r e n t (m A )

TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

Supply Voltage (V)

Fig. 9 Non-Switching Current

S u p p l y C u r r e n t (

μ

A )

Fig. 10

Feedback Pin Voltage

F e e d b a c k V o l t a g e (V )

Temperature (°C)

Output Current (mA)

Fig. 11 Efficiency vs. Output Current (L1=10μH, test circuit refer to p.3)

E f f i c i e n c y (%)

Output Current (mA)

Fig. 12

Efficiency vs. output current (L1=22μH, test circuit refer to p.3)

E f f i c i e n c y (%)

Fig. 13(a) Maximum Output current vs. Supply Voltage

(L1: 10μH, test circuit refer to p.3)

M a x i m u m O u t p u t C u r r e n

t (m A )

Supply Voltage (V)

0Fig. 13(b) Maximum Output Current vs. Supply Voltage

(L1:22μH, test circuit refer to p.3)

M a x i m u m O u t p u t C u r r e n t (m A )

Supply Voltage (V)

TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

Fig. 14 Operation Wave Form

(V IN =5V; V OUT =12V, L1=22μH; R1=105K;

R2=12K;C3=1nF;I OUT =200mA, test circuit refer to p.3)

V OUT V SW I

LX

Fig. 15 Operation Wave Form

(V IN =3V;V OUT =5V;L1=10μH;R1=36K;R2=12K; C3=39pF;I OUT =200mA, test circuit refer to p.3)

V OUT V

LX

I

LX

Fig. 16 Load Step Response

(V IN =3.3V; V OUT =5V;L1=10μH;I OUT =5mA to 200mA,

test circuit refer to p.3)

V OUT

I

LX

Fig. 17 Load Step Response

(V IN =5V ; V OUT =12V ;L1=22μH;I OUT =5mA to 150mA,

test circuit refer to p.3)

V OUT

I LX

Fig. 18 Start-Up from Shutdown (V IN =3.3V ;V OUT =13V ;R LOAD =300?,

test circuit refer to p.3)

V OUT

SHDN I LX

BLOCK DIAGRAM

SHDN

SS

LX FB

GND PIN DESCRIPTIONS

PIN 1: LX - Power Switching Connection.

Connect LX to inductor and

output rectifier. Keep the

distance between the

components as close to LX as

possible.

PIN 2: GND - Ground.

PIN 3: FB - Feedback Input. Connect a

resistive voltage-divider from the

output to FB to set the output

voltage.

PIN 4: SHDN- Shutdown Input. Drive SHDN

low to turn off the converter. To

automatically start the converter,

connect SHDN to IN. Drive

SHDN with a slew rate of

0.1V/μs or greater. Do not leave

SHDN unconnected.SHDN

draws up to 50μA.

PIN 5: SS - Soft-Start Input. Connect a

soft-start capacitor from SS to

GND in order to soft-start the

converter. Leave SS open to

disable the soft-start function. PIN 6: IN - Internal Bias Voltage Input.

Connect IN to the input voltage

source. Bypass IN to GND with

a capacitor sitting as close to IN

as possible.

APPLICATION INFORMATION Inductor Selection

A 15μH inductor is recommended for most

AIC1896 applications. Although small size and high efficiency are major concerns, the inductor should have low core losses at 1.4MHz and low DCR (copper wire resistance).

Capacitor Selection

The small size of ceramic capacitors makes them ideal for AIC1896 applications. X5R and X7R types are recommended because they retain their capacitance over wider ranges of voltage and temperature than other types, such as Y5V or Z5U. A 4.7μF input capacitor and a 1μF output capacitor are sufficient for most AIC1896 applications.

Diode Selection

Schottky diodes, with their low forward voltage drop and fast reverse recovery, are the ideal choices for AIC1896 applications. The forward voltage drop of a Schottky diode represents the conduction losses in the diode, while the diode capacitance (C T or C D) represents the switching losses. For diode selection, both forward voltage drop and diode capacitance need to be considered. Schottky diodes with higher current ratings usually have lower forward voltage drop and larger diode capacitance, which can cause significant switching losses at the 1.4MHz switching frequency of AIC1896. A Schottky diode rated at 100mA to 200mA is sufficient for most AIC1896 applications.

LED Current Control

LED current is controlled by feedback resistor (R1 in Fig. 1). The feedback reference is 1.23V. The LED current is 1.23V/R1. In order to have

accurate LED current, precision resistors are preferred (1% recommended). The formula for R1 selection is shown below.

R1 = 1.23V/I LED(1)

Open-Circuit Protection

In the cases of output open circuit, when the LEDs are disconnected from the circuit or the LEDs fail, the feedback voltage will be zero. AIC1896 will then switch to a high duty cycle resulting in a high output voltage, which may cause SW pin voltage to exceed its maximum 30V rating. A zener diode can be used at the output to limit the voltage on SW pin (Fig. 20). The zener voltage should be larger than the maximum forward voltage of the LED string. The current rating of the zener should be larger than 0.1mA.

Dimming Control

There are three different types of dimming control circuits as follows:

1. Using a PWM signal

PWM brightness control provides the widest dimming range by pulsing LEDs on and off at full and zero current, repectively. The change of average LED current depends on the duty cycle of the PWM signal. Typically, a 0.1kHz to 10kHz PWM signal is used. Two applications of PWM dimming with AIC 1896 are shown in Fig 21. One, as fig. 21(a), uses PWM signal to drive SHDN pin directly for dimming control. The other, as fig. 21(b), employs PWM signal going through a resistor to drive FB pin. If the SHDN pin is used, the increase of duty cycle results in LED brightness enhancement. If the FB pin is used, on the contrary, the increase of duty cycle will decrease its brightness. In this application, LEDs

are dimmed by FB pin and turned off completely by SHDN.

2. Using a DC Voltage

For some applications, the preferred method of a dimming control uses a variable DC voltage to adjust LED current. A dimming control using a DC voltage is shown as Fig. 22. As DC voltage increases, the voltage drop over R2 increases and the voltage drop over R1 decreases.

Cautiously selecting R2 and R3 is essential so that the current from the variable DC source is much smaller than the LED current and much larger than the FB pin bias current. With a VDC ranging from 0V to 5V, the selection of resistors in Fig. 22 results in dimming control of LED current from 20mA to 0mA, respectively.

3. Using a Filtered PWM Signal

Filtered PWM signal can be considered as an adjustable DC voltage. It can be used to replace the variable DC voltage source in dimming control. The circuit is shown in Fig. 23.

V IN

C3

μF Fig. 19 White LED Driver with Open-Circuit Protection

PWM

OFF

(a) (b)

Fig. 20 Dimming Control Using a PWM Signal

ON

OFF

Fig. 21 Dimming Control Using a DC Voltage Fig. 22 Dimming Control Using a Filtered PWM Signal APPLICATION EXAMPLES

C3

μF

=20mA

V IN

Fig. 23 1-Cell Li-Ion Powered Driver for eight White LEDs with Open-Circuit Protection

Vout *R2 *L1 5V

9V 12V 18V 24V

36K 75k 105k 160k 220k

10uH 10uH 10uH 22uH 22uH

Fig. 24 Typical Step up Application Circuit

4.7μV IN

Fig. 25 1-Cell Li-Ion to ±15V/5mA Dual Output Converter for LCD Bias

5V IN

V OUT =40V/10mA

0.1uF

Fig. 26 High 40V Output Voltage for Electrophoretic Display (EPD) Application

Fig. 27 Three output voltage for LCD

PHYSICAL DIMENSIONS (unit: mm)

TSOT-23-6

VIEW B

SEATING PLANE

GAUGE PLANE SECTION A-A

SEE VIEW B

0°

0.700.30

1.50

2.602.800.080.30 0e θ

L1L e1c E E1

D b A2

A10.95 BSC 8°0.601.90 BSC

0.60 REF

0.901.70

3.003.000.220.500.10 -MIN.S

Y M B O L

A 1.00MAX.TSOT-23-6MILLIMETERS Note : 1. Refer to JEDEC MO-193AA.

2. Dimension "D" does not include mold flash, protrusions or gate burrs. Mold flash, protrusion or gate burrs shall not exceed 6 mil per side.

3. Dimension "E1" does not include inter-lead flash or protrusions.

4. Controlling dimension is millimeter, converted inch dimensions are not necessarily exact.

SOT-23-6

Note :

Information provided by AIC is believed to be accurate and reliable. However, we cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in an AIC product; nor for any infringement of patents or other rights of third parties that may result from its use. We reserve the right to change the circuitry and specifications without notice.

Life Support Policy: AIC does not authorize any AIC product for use in life support devices and/or systems. Life support devices or systems are devices or systems which, (I) are intended for surgical implant into the body or (ii) support or sustain life, and whose failure to perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury to the user.

VIEW B

SEATING PLANE

GAUGE PLANE SECTION A-A

SEE VIEW B

0°

0.900.30

1.50

2.602.800.080.300.05e θ

L1L e1c E

E1D

b A2

A10.95 BSC 8°0.601.90 BSC

0.42 REF

1.301.70

3.003.000.220.500.150.95MIN.S Y M B O L

A 1.45MAX.SOT-23-6MILLIMETERS Note : 1. Refer to JEDEC MO-178AB.

2. Dimension "D" does not include mold flash, protrusions or gate burrs. Mold flash, protrusion or gate burrs shall not exceed 10 mil per side.

3. Dimension "E1" does not include inter-lead flash or protrusions.

4. Controlling dimension is millimeter, converted inch dimensions are not necessarily exact.