Hydrothermal Synthesis and Pseudocapacitance Properties of MnO2 Nanostructures

Hydrothermal Synthesis and Pseudocapacitance Properties of MnO2Nanostructures

V.Subramanian,?Hongwei Zhu,?Robert Vajtai,?P.M.Ajayan,?and Bingqing Wei*,?

Department of Electrical and Computer Engineering and Center for Computation and Technology,

Louisiana State Uni V ersity,Baton Rouge,Louisiana70803,and Rensselaer Nanotechnology Center

and Department of Materials Science and Engineering,Rensselaer Polytechnic Institute,1108th Street,

Troy,New York12180

Recei V ed:August4,2005;In Final Form:September8,2005

The effect of varying the hydrothermal time to synthesize manganese oxide(MnO2)nanostructures was

investigated along with their influence on structural,morphological,compositional,and electrochemical

properties in supercapacitor electrode materials.XRD and TEM studies showed that the MnO2prepared in

shorter hydrothermal dwell time was a mixture of amorphous and nanocrystalline particles,and there was an

evolution of crystallinity of the nanostructures as the dwell time increased from1to18h.Interestingly,

SEM,TEM,and HRTEM revealed a variety of structures ranging from nanostructured surface with a distinct

platelike morphology to nanorods depending upon the hydrothermal reaction time employed during the

preparation of the manganese oxide:increasing the amount of individual nanorods in the materials prepared

with longer hydrothermal reaction time.The surface area of the synthesized nanomaterials varied from100

to150m2/g.Electrochemical properties were evaluated using cyclic voltammetry(CV)and galvanostatic

charge-discharge studies,and the capacitance values were in the range72-168F/g depending upon synthesis

conditions.The formation mechanism of the nanorods and their impact on the specific capacitance were

discussed in detail.

Introduction

In recent years,due to environmental issues and depleting fossil fuels,interest in the development of alternative energy storage/conversion devices with high power and energy densities catering the present day demands has increased to a greater extent.Electrochemical capacitors or supercapacitors(SCs)have gained enormous attention owing to their potential applications ranging from mobile devices to electric vehicles(EV).1SCs are broadly classified into two categories,electrical double layer capacitors(EDLCs)and pseudocapacitors depending on the nature of charge storage mechanism.EDLCs exhibit a non-faradic reaction with accumulation of charges at the electrode-electrolyte interfaces,while pseudocapacitors show faradic redox reactions.

Different types of carbonaceous material ranging from amorphous carbons to carbon nanotubes have been used as electrode materials in EDLCs.2-5In the case of pseudocapaci-tors,various noble and transition metal oxides such as RuO2, IrO2,NiO,CoO x,SnO2,and MnO2were used as electrode materials.6-10Of all the transition metal oxides studied as pseudocapacitor materials,hydrated RuO2has been found to be most promising.However,the high cost of RuO2has prompted the research community to focus on other transition metal oxides such as MnO2,NiO,and so forth,mainly because of the involved cost-effectiveness.In addition,hydrated RuO2 shows excellent performance mostly only in a highly acidic electrolyte such as sulfuric acid.The basic idea behind the choice of highly acidic electrolyte solutions for SC applications mainly relates to the fast charge and discharge leading to a high power density.This is because protons have better access not only to the surface of the electrode but also to the interior of the electrode than larger alkali ions such as K+or Na+.6Hence, the chemisorption of the H+in an acidic-hydrated oxide electrode system is exceptionally fast,leading to a promising pseudocapacitor material.6However,the main disadvantage of using a highly acidic electrolyte is the dissolution of metal oxide over a period of cycling time.This leads to SC showing a faster fading in capacitance with respect to cycling.Hence,alternative materials which are much cheaper and more promising in a neutral electrolyte system such as Na2SO4,KCl,LiCl,and so forth have been investigated in recent years.11-13Of the various non-noble metals or transition metal oxides studied,MnO2 enjoys a place of pride because of its lower cost and environ-mentally benign nature.Beyond these advantageous properties, MnO2is very promising in a neutral electrolyte system.11-17 Manganese oxides as pseudocapacitor electrode materials were synthesized using different techniques such as simple reduction,coprecipitaion,sol-gel,thermal decomposition,and so forth.11-17Also,various thin film electrodes of MnO2were synthesized via electrochemical and chemical routes.18,19Kim and Papov prepared MnO2and Pb,Ni-mixed MnO2by the reduction of KMnO4with Mn/Ni/Pb acetate solutions.11Jeong and Manthiram reported the synthesis of MnO2by the reduction of KMnO4using potassium borohydride,sodium dithionate,and sodium hypophosphite.12Lee et al.synthesized MnO2by a simple thermal decomposition of finely ground KMnO4powder at different temperatures ranging300-1000°C.13Simple precipitation of MnO2was achieved by mixing aqueous solu-tions of KMnO4and MnSO4.14Precipitation of MnO2from aqueous solutions of Mn acetate and KMnO4was also re-ported.20

Hydrothermal synthesis has been an interesting technique to prepare materials with different nanoarchitectures such as

*To whom correspondence should be addressed.Email:weib@https://www.wendangku.net/doc/fb5115987.html,.?Louisiana State University.

?Rensselaer Polytechnic Institute.20207

J.Phys.Chem.B2005,109,20207-20214

10.1021/jp0543330CCC:$30.25?2005American Chemical Society

Published on Web10/12/2005

nanowires,nanorods,nanobelts,nanourchins,and so forth.21,22 The main advantages of the hydrothermal technique over other soft chemical routes are the abilities to control the nanostructures ranging from nanoparticles to nanorods or nanourchins to nanotubes by properly choosing the temperature or time of the reaction or the active fill level in the pressure vessel or solvent used for the reaction without any major structure-directing agents or templates.Each structure has its own merits when used in a potential application such as photocatalyst,electrodes in re-chargeable batteries,supercapacitors,electrocatalysts for fuel cells,and so forth.The nature of the nanomaterial formed by the hydrothermal route depends on various factors such as solvent used,temperature and time of the reaction,effective fill level in the pressure vessel,and so forth.The factors mentioned above can be judicially chosen to get the desired architecture.Apart from the aforementioned advantages,the starting material for the reaction needs not be soluble as in the case of other soft or wet chemical methods such as sol-gel or coprecipitation.MnO2has been prepared using hydrothermal techniques in different nano phases such as rods,urchins,wires, and so forth.21,22

In this paper,we report the synthesis of various nanostructures of MnO2by a hydrothermal route under mild conditions.The change in the nanoarchitectures was achieved by simply tuning the hydrothermal reaction time.The corresponding variation in morphology,surface properties,and electrochemical properties as supercapacitor electrodes were studied elaborately and discussed in detail.

Experimental Section

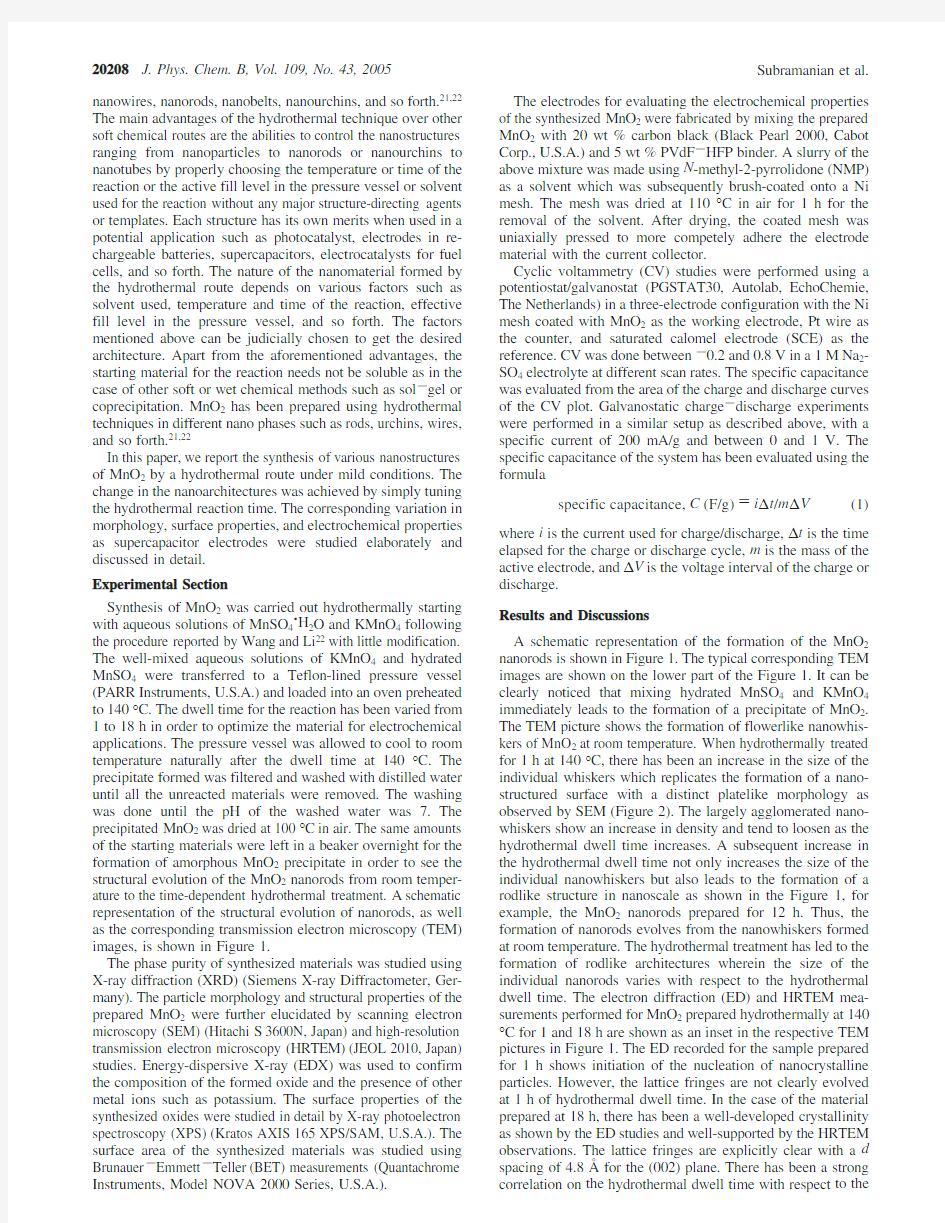

Synthesis of MnO2was carried out hydrothermally starting with aqueous solutions of MnSO4?H2O and KMnO4following the procedure reported by Wang and Li22with little modification. The well-mixed aqueous solutions of KMnO4and hydrated MnSO4were transferred to a Teflon-lined pressure vessel (PARR Instruments,U.S.A.)and loaded into an oven preheated to140°C.The dwell time for the reaction has been varied from 1to18h in order to optimize the material for electrochemical applications.The pressure vessel was allowed to cool to room temperature naturally after the dwell time at140°C.The precipitate formed was filtered and washed with distilled water until all the unreacted materials were removed.The washing was done until the pH of the washed water was7.The precipitated MnO2was dried at100°C in air.The same amounts of the starting materials were left in a beaker overnight for the formation of amorphous MnO2precipitate in order to see the structural evolution of the MnO2nanorods from room temper-ature to the time-dependent hydrothermal treatment.A schematic representation of the structural evolution of nanorods,as well as the corresponding transmission electron microscopy(TEM) images,is shown in Figure1.

The phase purity of synthesized materials was studied using X-ray diffraction(XRD)(Siemens X-ray Diffractometer,Ger-many).The particle morphology and structural properties of the prepared MnO2were further elucidated by scanning electron microscopy(SEM)(Hitachi S3600N,Japan)and high-resolution transmission electron microscopy(HRTEM)(JEOL2010,Japan) studies.Energy-dispersive X-ray(EDX)was used to confirm the composition of the formed oxide and the presence of other metal ions such as potassium.The surface properties of the synthesized oxides were studied in detail by X-ray photoelectron spectroscopy(XPS)(Kratos AXIS165XPS/SAM,U.S.A.).The surface area of the synthesized materials was studied using Brunauer-Emmett-Teller(BET)measurements(Quantachrome Instruments,Model NOVA2000Series,U.S.A.).

The electrodes for evaluating the electrochemical properties of the synthesized MnO2were fabricated by mixing the prepared MnO2with20wt%carbon black(Black Pearl2000,Cabot Corp.,U.S.A.)and5wt%PVdF-HFP binder.A slurry of the above mixture was made using N-methyl-2-pyrrolidone(NMP) as a solvent which was subsequently brush-coated onto a Ni mesh.The mesh was dried at110°C in air for1h for the removal of the solvent.After drying,the coated mesh was uniaxially pressed to more competely adhere the electrode material with the current collector.

Cyclic voltammetry(CV)studies were performed using a potentiostat/galvanostat(PGSTAT30,Autolab,EchoChemie, The Netherlands)in a three-electrode configuration with the Ni mesh coated with MnO2as the working electrode,Pt wire as the counter,and saturated calomel electrode(SCE)as the reference.CV was done between-0.2and0.8V in a1M Na2-SO4electrolyte at different scan rates.The specific capacitance was evaluated from the area of the charge and discharge curves of the CV plot.Galvanostatic charge-discharge experiments were performed in a similar setup as described above,with a specific current of200mA/g and between0and1V.The specific capacitance of the system has been evaluated using the formula

where i is the current used for charge/discharge,?t is the time elapsed for the charge or discharge cycle,m is the mass of the active electrode,and?V is the voltage interval of the charge or discharge.

Results and Discussions

A schematic representation of the formation of the MnO2 nanorods is shown in Figure1.The typical corresponding TEM images are shown on the lower part of the Figure1.It can be clearly noticed that mixing hydrated MnSO4and KMnO4 immediately leads to the formation of a precipitate of MnO2. The TEM picture shows the formation of flowerlike nanowhis-kers of MnO2at room temperature.When hydrothermally treated for1h at140°C,there has been an increase in the size of the individual whiskers which replicates the formation of a nano-structured surface with a distinct platelike morphology as observed by SEM(Figure2).The largely agglomerated nano-whiskers show an increase in density and tend to loosen as the hydrothermal dwell time increases.A subsequent increase in the hydrothermal dwell time not only increases the size of the individual nanowhiskers but also leads to the formation of a rodlike structure in nanoscale as shown in the Figure1,for example,the MnO2nanorods prepared for12h.Thus,the formation of nanorods evolves from the nanowhiskers formed at room temperature.The hydrothermal treatment has led to the formation of rodlike architectures wherein the size of the individual nanorods varies with respect to the hydrothermal dwell time.The electron diffraction(ED)and HRTEM mea-surements performed for MnO2prepared hydrothermally at140°C for1and18h are shown as an inset in the respective TEM pictures in Figure1.The ED recorded for the sample prepared for1h shows initiation of the nucleation of nanocrystalline particles.However,the lattice fringes are not clearly evolved at1h of hydrothermal dwell time.In the case of the material prepared at18h,there has been a well-developed crystallinity as shown by the ED studies and well-supported by the HRTEM observations.The lattice fringes are explicitly clear with a d spacing of4.8?for the(002)plane.There has been a strong correlation on the hydrothermal dwell time with respect to the specific capacitance,C(F/g))i?t/m?V(1)

20208J.Phys.Chem.B,Vol.109,No.43,2005Subramanian et al.

pore structure and surface area of the MnO 2nanostructures,which,in turn,has a direct effect on the electrochemical properties of the materials.

The evolution of the nanostructurs of MnO 2prepared at different hydrothermal dwell time is clearly shown with SEM images in Figure 2.As can be seen from the pictures,there has been a strong correlation between the time and the resulting nanostructure.For the material prepared at room temperature,there have been largely agglomerated nanowhiskers of MnO 2which change to nanostructured platelike morphology on hydrothermal treatment for 1h.Increasing the dwell time to 3h and 6h showed a corresponding change in the nanoarchitec-ture with few rods evolving in addition to the nanostructured platelike morphology.Further increasing the hydrothermal reaction time to 12h and 18h leads to formation of large amount of individual nanorods.All these morphological manipulations are the biggest advantage of the hydrothermal technique.The XRD patterns for the prepared MnO 2at different time are shown in Figure 3.The material prepared at room temper-ature showed an amorphous MnO 2having peaks evolving to an R -MnO 2structure,and the details are discussed elsewhere.23In the case of MnO 2prepared at 140°C for 1h,the system showed evolution of the nucleation of the nanocrystalline nature of the MnO 2particles (also see inset of Figure 1)with peaks indexable in R -MnO 2structure.The broad peak features show the mixture of amorphous and nanocrystalline nature of the sample because of the nanowhiskers of flowerlike architecture of MnO 2.There is an increase in crystallinity with respect to the increase of the hydrothermal dwell time from 1h to 18h as evidenced by the appearance of sharper peaks (also,please see the inset of the TEM in Figure 1for 18h MnO 2showing ED and HRTEM).As can be seen from the figure,all the peaks for the sample prepared at a dwell time of 12h and longer can be indexed to a pure tetragonal phase (space group I 4/m (no.87))of R -MnO 2(JCPDS 44-0141).There has always been a strong correlation between the crystallinity and the surface area of the system on the electrochemical properties as discussed later.N 2adsorption -desorption studies were performed to deter-mine the specific surface area of the MnO 2prepared at different hydrothermal reaction times.The BET surface area was found to be 100m 2/g for 1h hydrothermally treated sample.Interest-ingly,an increase in the hydrothermal dwell time to 6h and 12h showed an increase in the surface area to 132m 2/g and 150m 2/g,respectively.Although XRD showed a more amorphous material at shorter dwell time than longer,the surface area is more dependent on the pore structure where the N 2adsorption -desorption takes place.Here,as explained previously in the schematic model for the evolution of nanorods,the materials prepared with a shorter dwell time exhibit more agglomerated nanowhiskers of MnO 2,which eventually leads to the nanorod

Figure 1.Schematic representations and TEM images of formation of MnO 2nanorods under hydrothermal conditions.Inset of 1h and 18h TEM shows the ED and HRTEM of the MnO 2prepared at the respective hydrothermal time.

MnO 2Nanostructures J.Phys.Chem.B,Vol.109,No.43,2005

20209

architecture when the dwell time is increased.This leads to the increase in pore volume associate with the system.However,the pore diameters for MnO 2prepared at different dwell times were in the mesoporous region with a value of 8nm.

XPS is an excellent technique to understand the oxidation state of the transition metal ion and the relative composition of the synthesized material.Typical XPS spectra for the MnO 2prepared for 1h are shown in Figure 4.Similar spectra were observed for the MnO 2prepared for different dwell times.The Mn 3s,Mn 2p,and O 1s spectra were used to evaluate the oxidation state of the Mn in MnO 2prepared for different hydrothermal times.It has been well-established by many earlier studies that the Mn 3s will have a splitting and a doublet due to the parallel spin coupling of the 3s electron with the 3d electron during the photoelectron ejection.14We have found the doublet for the Mn 3s as reported earlier.Most important,the separation between the peaks of the doublet will give an idea of the oxidation state of the Mn ion.In the present study for all the reaction times,the difference of the Mn 3s spectra in the peak energy for the splitting corresponds to values between 4.7and 4.8eV.According to Toupin et al.14and other research-ers,15,16when the oxidation state of Mn is +4,the binding energy difference is in the range 4.7-4.8eV.This clearly shows that the MnO 2prepared by the hydrothermal technique has resulted in MnO 2phase,consistent with XRD results.Also,the Mn 2p 3/2and 2p 1/2in the Mn 2p spectra for MnO 2prepared at different dwell times of 1,6,and 12h were found to be 642and 653.8eV,642.3and 654.1eV,and 642.1and 654eV,respectively.These values agree well with those reported for the MnO 2indicating that the oxidation state is +4and further confirming the earlier claim.

Similarly,the amount of potassium present in the synthesized MnO 2was quantified from K 2p spectra relative to the Mn 2p.It is interesting to note that the potassium content seems to

Figure 2.SEM images of MnO 2prepared at different hydrothermal dwell times.

20210J.Phys.Chem.B,Vol.109,No.43,2005Subramanian et

al.

increase with the increase in the hydrothermal reaction time from1h to12h.The relative percentage of potassium with respect to manganese can be estimated from the K2p and Mn 2p spectra.The K/Mn ratios for MnO2prepared at1,6,and12 h were0.13,0.15,and0.16,respectively.This is probably due to the incorporation of potassium ion under the autogenous pressure condition into the MnO2matrix as the dwell time is increased.The presence of a larger quantity of K+inside the porous MnO2matrix will have an appreciable effect on the electrochemical properties.

Typical cyclic voltammograms recorded at a scan rate of5 mV/s for MnO2prepared at140°C for different time are shown in Figure5.It can be seen from the figures that there has been an ideal capacitive behavior with the plots showing an almost rectangular profile.The area under the CV curve can be used to estimate the capacitance of the system.The variation of specific capacitance with respect to the hydrothermal dwell time is shown in Table1.MnO2prepared for6h showed the maximum capacitance with a value of168F/g.There has been an increase in capacitance from140F/g for the sample prepared at1h to168F/g for the sample prepared for6h,which then decreased to118F/g for the12h and72F/g for18h.Similar results have been observed in the case of temperature-dependent capacitance for MnO2prepared at different temperatures.14Also, the system prepared at140°C for1h is more amorphous,and there is a large agglomeration of the particles or the slablike morphology,which prevents the accessibility of the electrolyte for the electrochemical reactions.The increase in the hydro-thermal dwell time to3h and6h loosens the agglomeration leading to better capacitance because of better electrolyte accessibility.The variation of specific capacitance with respect to dwell time is attributed to the increase in the crystallinity, specific surface area,coexistence of more metal ions such as K+,and the loss of the chemically and physically adsorbed water14-25from MnO2.

The cycling capability of the MnO2-6h electrode was studied galvanostatically at a constant current of200mA/g and between 0and1V.Typical charge-discharge curves for the MnO2-6h sample are shown in Figure6.The specific capacitance was found to be168F/g which is very much comparable to that calculated from the CV studies.Further work on long cycle performance and impedance spectroscopy is in progress.

It has to be mentioned here that,since the present electrode is a composite one with a significant amount of Black Pearl 2000(BP2000),which is a high surface area material that can contribute to the total capacity of the material,the contribution has to be subtracted from the total specific capacitance.The values reported in this paper are after the elimination of the contribution from BP2000.The capacitance of BP2000has been estimated by Kim and Popov to be70F/g11in a1M Na2SO4 electrolyte.The specific capacitance of BP2000in1M H2SO4 is216F/g,which is much lower than in a1M Na2SO4 electrolyte,which is mainly due to size considerations arising from the Na+and H+ions and the formation of the double layer at the electrode-electrolyte interface.11Hence,it is clear that the ionic size in the electrolyte plays a critical role in the resultant capacitance of a system.

There have been two mechanisms proposed for the charge storage in MnO2-based electrodes.The first one is based on the concept of intercalation of H+or alkali metal cations such as Na+in the electrode during reduction and deintercalation upon oxidation24

The second one is the adsorption of cations in the electrolyte on the MnO2electrode13

In the present study,the redox process is mainly governed by the insertion and deinsertion of Na+and or H+from the electrolyte into the porous MnO2matrix.The reason for the increase in the capacitance with the increase in the hydrothermal treatment time may be attributed to the increase in the surface area of the material from100to132m2/g when the reaction time is increased from1to6h.However,there has been an observed decrease in capacitance for the material prepared for 12h,which has a higher surface area(150m2/g)than that for 6h.This has to be carefully considered,as many parameters

Figure3.X-ray diffraction patterns of MnO2synthesized hydrother-mally at140°C for different times.TABLE1:Summary of Structural,Surface/Morphological, and Electrochemical Properties of Nanostructured MnO2 Prepared Hydrothermally at140°C for Different Times

synthesis

time(h)structure

surface

area

(m2/g)

specific

capacitance a

(F/g) 1nanostructured surface

with a distinct

platelike morphology

100140

3nanostructured surface

with a distinct

platelike morphology

140

6nanostructured surface

with a distinct

platelike morphology

+nanorods

132168

9nanostructured surface

with a distinct

platelike morphology

+nanorods

115

12nanorods150118

18nanorods72

a Calculated from CV studies at a scan rate of5mV/s between-0.2 and0.8V in a1M Na2SO4aqueous electrolyte.

MnO

2

+C++e-T MnOOC+(2)

(MnO

2

)

surface

+C++e-T(MnO

2

-C+)

surface

(3)

MnO2Nanostructures J.Phys.Chem.B,Vol.109,No.43,2005

20211

such as pore structure,pore volume,and chemical composition have to be taken into account when discussing the electrochemi-cal properties.Similar results of systems showing lower capacitance for a larger surface area material have been reported in the literature.12,16,17

Two important parameters have to be considered in present study,the surface area and the effective potassium concentration in the MnO 2matrix.It has been reported that an increase in specific surface area will lead to an increase in the specific capacitance and also a decrease in the molecular weight will lead to a same result.Here,there has been an increase in the specific surface area and also a corresponding increase in the molecular weight because of the presence of more K +in the MnO 2matrix when the reaction time is increased from 1to 12h as we discussed earlier.The increase in surface area in the case of the 12h sample does not prove that effective because longer hydrothermal time leads to a system with more crystal-linity but less chemisorbed water as well.Also,an increase in the presence of the K +ion inside the MnO 2matrix will have an impeding effect for the diffusion of the Na +ion from the electrolyte,which is the predominant reaction for the redox process.This is because the ionic radius of K +is much bigger than that of Na +(K +)1.33?and Na +)0.95?),which will obviously have an effect on the diffusion of Na +ions.The increase of the potassium ion content is a result of incorporation of K +from the KMnO 4during the hydrothermal reaction.So,

Figure 4.Typical XPS spectra for MnO 2prepared at 140°C for 1h.

20212J.Phys.Chem.B,Vol.109,No.43,2005Subramanian et

al.

it is clear that the surface area is not the only factor that determines the electrochemical properties.Other parameters such as coexisting ions and their impact must also have to be considered.The structural,surface/morphological,and electro-chemical properties of the prepared nanostructured MnO 2samples for different synthesis times are summarized in Table 1.From the present study,it is conclusive that the MnO 2prepared for 6h has an optimum surface area and K +content and hence showed the best electrochemical properties.The effect of scan rate was performed by varying the scan rate of CV as 1,2,5,10,25,and 50mV/s on the MnO 2sample prepared for 6h.As the scan rate increases,the CV profile deviates from the ideal capacitive behavior.This is mainly because the redox reactions depend on the insertion -deinsertion of the alkali ion or protons from the electrolyte as explained earlier in eqs 2and 3.At slower scan rates,the diffusion of ions from the electrolyte can gain access to almost all available pores of the electrode,leading to a complete insertion reaction

Figure 5.Cyclic voltammograms of MnO 2nanostructures prepared at different dwell times recorded at a scan rate of 5mV/s in a 1M Na 2SO 4aqueous electrolyte.

MnO 2Nanostructures J.Phys.Chem.B,Vol.109,No.43,2005

20213

and hence a reduction process,and the reverse happens during the deinsertion process as well.But,when the scan rate is increased,the effective interaction between the ions and the electrode is greatly reduced;hence,there is a reduction in capacitance.The decrease in capacitance with respect to the increase in the scan rate,which is predominantly due to the slow diffusion of Na +ions into the pores of MnO 2,i.e.,when the scan rate is higher the effective utilization for the redox reaction has been limited only to the outer surface of MnO 2electrode.The outer charge and the total charge have been calculated by following the earlier works,14-17and it has been found that the total charge is 190C/g and the outer charge is 83C/g.The difference between the outer charge,q T *,and q o*gives the inner voltammetric charge q i *,which is the inacces-sible active surface area for storage when the scan rate is high.26This indicates that the effective charge when the scan rate is high arises not from the entire electrode but instead the outer surface near the electrode -electrolyte interface.The main reason for such a behavior is that the higher sweep rate prevents the accessibility of Na +ions to all the pores of the electrode.Conclusions

MnO 2with different nanoarchitectures has been successfully synthesized by varying the hydrothermal reaction time at 140°C,and the pseudocapacitance properties of hydrothermally prepared MnO 2nanostructures were studied for the first time.The XRD,TEM,and BET studies showed an amorphous phase at shorter dwell time,and increasing the time led to an increase of crystalline nanorods as well as of the surface area.MnO 2

nanostructures prepared hydrothermally at 140°C for 6h showed the best performance in the present study with a specific capacitance of 168F/g when cycled at a constant current of 200mA/g.Increasing the scan rate in CV studies revealed a decrease in specific capacitance.Further work is in progress to see the effect of long cycle performance on the electrode structure and the associated structural and impedance changes.Acknowledgment.The authors gratefully acknowledge financial support from Louisiana Board of Regents under the award number LEQSF(2005-08)-RD-B-05and National Science Foundation under the NSF award number DMI-0457555.R.V.and P.M.A.are grateful to Nanoscale Science and Engineering Initiative of the National Science Foundation under NSF award number DMR-0117792.

References and Notes

(1)Conway,B.E.Electrochemical Capacitors:Scientific Fundamen-tals and Technological Applications ;Kluwer Academic/Plenum:New York,1999.

(2)Frackowiak,E.;Be ′guin,F.

Carbon 2001,39,937.

(3)Endo,M.;Maeda,T.;Takeda,T.;Kim,Y.J.;Koshiba,K.;Hara,H.;Dresselhaus,M.S.J.Electrochem.Soc.2001,148,A910.

(4)Taberna,P.L.;Simon,P.;Fauvarque,J.F.J.Electrochem.Soc.2003,150,A292.

(5)Bonhomme,F.;Lassegues,J.C.;Servant,L.J.Electrochem.Soc.2001,148,E450.

(6)Zheng,J.P.;Cygan,P.J.;Jow,T.R.J.Electrochem.Soc.1995,142,2699.

(7)Liu,K.C.;Anderson,M.A.J.Electrochem.Soc.1996,143,124.(8)Yoon,Y.S.;Cho,W.I.;Lim,J.H.;Choi,D.J.J.Power Sources 2001,101,126.

(9)Conway,B.E.;Briss,V.;Wojtowicz J.Power Sources 1997,66,1.

(10)Lin,C.;Ritter,J.A.;Popov,B.N.J.Electrochem.Soc.1998,145,4097.

(11)Kim,H.;Popov,B.N.J.Electrochem.Soc.2003,150,D56.(12)Jeong,Y.U.;Manthiram,A.J.Electrochem.Soc.2002,149,A1419.(13)Lee,H.Y.;Goodenough,J.B.J.Solid State Chem.1999,144,220.

(14)Toupin,M.;Brousse,T.;Belanger,D.Chem.Mater.2002,14,3946.(15)Toupin,M.;Brousse,T.;Belanger,D.Chem.Mater.2004,16,3184.(16)Reddy,R.N.;Reddy,R.G.J.Power Sources 2003,124,330.(17)Reddy,R.N.;Reddy,R.G.J.Power Sources 2004,132,315.(18)Pang,S.C.;Anderson,M.A.J.Mater.Res.2000,15,2096.(19)Hu,C.C.;Tsou,https://www.wendangku.net/doc/fb5115987.html,m.2002,4,105.

(20)Lee,H.Y.;Mannivanan,V.;Goodenough,J.B.C.R.Acad.Sci.Paris 1999,t.2,series II c,565.

(21)Du,G.H.;Yuan,Z.Y.;Van Tendeloo,G.Appl.Phys.Lett.2005,86,063113.

(22)Wang,X.;Li,https://www.wendangku.net/doc/fb5115987.html,mun.2002,764.(23)Subramanian,V.;Wei,B.Q.In preparation.

(24)Pang,S.C.;Anderson,M.A.;Chapman,T.W.J.Electrochem.Soc.2000,147,444.

(25)Bruke,A.J.Power Sources 2000,91,37.

(26)Soudan,P.;Gaudet,J.;Guay,D.;Belanger,D.;Schulz,R.Chem.Mater.2002,14,1210.

Figure 6.Typical charge -discharge cycling for MnO 2prepared at 140°C for 6h recorded at a constant current of 200mA/g.

20214J.Phys.Chem.B,Vol.109,No.43,2005Subramanian et al.

普通员工辞职申请书范文【三篇】

普通员工辞职申请书范文【三篇】 尊敬的xx人力资源部: 您好! 因为个人职业规划和一些现实因素,经过慎重考虑之后,特此提出离职申请,敬请批准。 在xx工作一年多的时间里,我有幸得到了各位领导及同事们的倾心指导及热情协助,在本职工作和音乐专业技能上,我得到了很大水准的提升,在此感谢xx提供给我这个良好的平台,这个年多的工作经验将是我今后职业生涯中的一笔宝贵财富。 在这里,特别感谢各位领导在过去的工作、生活中给予的大力支持与协助;尤其感谢xx,xx等,一年来对我的信任和关照,感谢所有给予过我协助的同事们。 望批准我的申请,并请协助办理相关离职手续,在正式离开之前我将认真继续做好当前的每一项工作。 祝公司事业蓬勃发展,前景灿烂。 申请人:### 20xx年xx月xx日 【篇二】 尊敬的韩总: 作为一名在酒店工作了大半年的员工,我对酒店有着一种格外亲切的感觉。每一个人在他年轻的时候,都有很多第一次,我当然也不例外。

我的第一份工作是在酒店,我最青春的三年也是在酒店度过的。 在这里,我学会了很多东西,能够跟同事们在一起工作,我觉得很开心,这里的每一位都是我的大哥大姐,我的叔叔阿姨,是他们教给了 我在学校里面学不到的知识,如何为人、如何处事、如何工作……在 酒店里,领导们也对我十分的关心,从刚进入酒店开始,我就感受到 从上至下的温暖。因为我是酒店里年龄还一般,还不算小,也从来没 有在这么大的集体里生活过,自不过然的,心里面就会产生一种被呵 护的感觉。这是一种以前在集体里未曾有过的感觉,很温馨,很自豪,而且它一直陪伴着我,直到我离开…… 但这种感觉不会随着我的离开而走远,我想我永远也不会忘记, 毕竟我以前生活在一个温暖而又温馨的集体里。韩总,还记得第一次 跟您近距离接触和理解是在20xx.3.16号。随着时间的流逝,斗转星移,您多年积累的工作经验与个人才华也得到充分的施展。您是我们 酒店的经理。在我上班之前,制定了一系列的政策与方针,重新定位 了酒店的经营策略,持续地尝试新的机制与奖励、分配办法,力争让 酒店的经济效益持续迈上新高,也让酒店员工的福利待遇如芝麻开花 一般节节高樊。,这才是为员工谋利益的举动,这才是一位被员工在 心里面所认可的经理。 而我,作为这个集体的一份子,更加感觉到您对员工的关心与培养。您肯定想到,酒店要想在竞争激烈的社会中立于不败之地,人才 的培养与发展是不可忽视的环节之一。因为我自身水平的不足,近期 的工作让我觉得力不从心,所以想公司提出了辞呈,忘领导批准。 申请人:### 20xx年xx月xx日 【篇三】 尊敬的公司领导:

范本政府申请报告范文

政府申请报告要怎么写呢?以下是为大家分享的3篇政府申请报告范文,供大家参考借鉴,欢迎浏览! 政府申请报告范文一: 关于向xx人民政府申请xx项目优惠政策的报告 xx人民政府: xx旅游地产暨现代农业建设项目是由(陕西xx集团)下属陕西xx房地产开发有限公司与xx房地产开发有限公司共同投资,根据《汉中市保护利用总体规划》,本着保护性利用自然资源的原则,在兼顾环境效益,合理利用生态资源,统筹城乡发展的基础上,力图打造的一个具有养生体验功能的高科技集旅游地产和现代农业示范区有机整合的地方发展项目。 一、xx旅游地产暨现代农业建设项目简介 xx旅游地产暨现代农业建设项目,将充分运用“文化传承、产品核心竞争力、价值附着”三大策略、“传统农业、现代农业、未来农业”三大板块、“互惠、分享、共赢”三大原则,进行整体规划。项目规划将综合考虑国家及汉中生态保护相关政策,把协调发展“三农问题”作为根本出发点。项目结合项目地良好的自然环境、当前现代农业的发展契机、西北地区休闲市场巨大需求,结合项目单位自身的人才、技术、管理、资金等资源等优势条件,利用农业为主线的链条式发展,以高端科技农业为主打,以规模特色农业为品牌,以休闲体验旅游为提升,将农业和旅游产业有机结合。建设国内外先进农业技术的引进转化示范区、农业专家课题示范区和自驾旅游集散中心。带动旅游观光、生态体验、餐饮住宿等辐射经济效益的升级。体现休闲自然的生活态度和生活方式,成为全国性的农业科技示范教育基地。实现第一产业、第二产业和第三产业的联动、互利和产业链升级发展。 xx项目以农业发展为基础,休闲养生体验为主题,旅游产业为拓展。项目实施后,将积极促进和改善xx区域的生态环境,打造优质生态宜居游乐生活,增进居民幸福度和营造社会和谐度。 项目总投入约亿,项目直接收益较高,可带来超过2亿的税收和6亿的衍生收益,并能解决农村剩余劳动力2000以上,可为这些劳动力带来每年2万元以上的收入,给武乡区域带来极大的综合效益。 二、项目投资单位简介 本项目投资单位:陕西xx房地产开发有限公司;具体实施单位:xx房地产开发有限公司;两公司均为陕西xx集团全资下属单位。 陕西xx集团是经由区政府领导、经贸局和xx房地产开发有限公司共同努力引入汉中,并成功注资落户的外来企业。 陕西xx集团,是以煤炭、电力为主导产业,以资源综合开发利用为宗旨,坚持节能环保发展观的新型能源企业。该公司先后被榆林市委、市人民政府授予“榆林市十佳企业”、“榆林市非公有制纳税十强企业”、“挂牌重点保护

fluid inclusions

The application of fluid inclusions in the mineralization lijin The department of geochemistry,Yangtze university Abstract. Fluid inclusion analysis is an important tool in modern studies of mineral deposits, as reflected by the statistics indicating that about a quarter of the papers published in Economic Geology contain fluid inclusion studies. Fluid inclusions play an important role in the classification of mineral deposits and in the study of the composition, temperature and pressure of mineralizing fluids. Among the principal mechanisms of ore precipitation, flu-id phase separation and fluid mixing derive their key evidence mainly from studies of fluid inclusions. Data on mineralizing fluid composition obtained from fluid inclusion analysis are key to understanding how metals were transported in hydrothermal fluids. Recent progresses in metal transport in vapor have been mainly contributed by fluid inclusion studies. Data on fluid temperature and pressure from fluid inclusion studies provide important constraints on hydrodynamic models of mineralization. Most metal ore deposits are formed in the geological fluid.The formation and characteristics of hydrothermal ore deposits are closely related including temperature, pressure and composition. Although these information can be gained through the study of macro geological characteristics of ore deposit and the geochemical characteristics of the mineral , but the composition of ore-forming fluid, temperature, and pressure from fluid inclusion is the most direct evidence.Fluid inclusion is the only remain in ancient ore-forming fluid. So, the study of fluid inclusion becomes one of the important ways of genesis research naturally. For Economic Geology sampling survey, the proportion of fluid inclusion research papers, from 5% in 1975 to 15% in 1985, 27% in 1995, then remained at about 25%, about 1 in 4 papers of deposits essay involves the study of fluid inclusions. Although the fluid inclusion research has expanded to petroleum geology, magma, and the earth's interior processes, etc.its mian application in the field of ore deposit research . The application of fluid inclusions in ore deposit has a lot of monographs. but these works focus on basic principles , methods of the study and the characteristics of different deposit types.This paper mainly discusses the application of fluid inclusions in the study of ore deposits. Keywords: geochemistry, fluid inclusions, hydrothermal deposits, mineralizing fluids, ore precipitation, metal transportation. 1.Fluid inclusion is one of the basis of the classification of the ore deposit According to the geological characteristics and genesis, ore deposit can be divided into different types, But at present very few scholars classify the ore deposits completely according to the geological characteristics, such as shear zone gold deposits, stratabound lead-zinc deposit or causes such as high temperature

辞职报告文本辞职报告范文大全

辞职报告文本辞职报告范文大全 辞职报告 (篇一) 尊敬的领导: 我很遗憾自己在这个时候向公司正式提出辞职申请。 来到公司也已经快两年了,在这近两年里,得到了公司各位同事的多方帮助,我非常感谢公司各位同事。正是在这里我有过欢笑,也有过泪水,更有过收获。公司平等的人际关系和开明的工作作风,一度让我有着找到了依靠的感觉,在这里我能开心的工作,开心的学习。或许这真是对的,由此我开始了思索,认真的思考。 但是最近我感觉到自己不适合做这份工作,同时也想换一下环境。我也很清楚这时候向公司辞职于公司于自己都是一个考验,公司正值用人之际,公司新的项目的启动,所有的后续工作在公司上下极力重视下一步步推进。也正是考虑到公司今后在这个项目安排的合理性,本着对公司负责的态度,为了不让公司因我而造成的决策失误,我郑重向公司提出辞职。 我考虑在此辞呈递交之后的2—4周内离开公司,这样您将有时间去寻找适合人选,来填补因我离职而造成的空缺,同时我也能够协助您对新人进行入职培训,使他尽快熟悉工作。 能为公司效力的日子不多了,我一定会把好自己最后一班岗,做好工作的交接工作,尽力让项目做到平衡过渡。离开这个公司,离开

这些曾经同甘共苦的同事,很舍不得,舍不得领导们的尊尊教诲,舍不得同事之间的那片真诚和友善。 在短短的两年时间我们公司已经发生了巨大可喜的变化,我很遗 憾不能为公司辉煌的明天贡献自己的力量。我只有衷心祝愿公司的业绩一路飙升!公司领导及各位同事工作顺利! (篇二) 尊敬的办公室人力资源管理领导: 我向公司正式提出辞职。 我自**日进入公司,到现在已经一年有余了,正是在这里我开始 踏上了社会,完成了自己从一个学生到社会人的转变。在过去的一 年多里,公司给予了我许多学习和锻炼的机会,开阔眼界、增长见识。我对公司给予的照顾表示忠心的感谢!但是,经过近段时间的思考, 我越来越迷惘!我越来越觉得现在的工作、生活离自己想要的越来越远。所以,我必须离开,去过我思想深处另一种有别于目前的生活。我想,生活应该是在选择到适合自己的道路以后,再持之以恒地坚持! 公司目前已经过了一年最忙的时间,是充电、整顿、储备人才的 时刻。相信,我的离开会很快有新生力量补充。因为这不是我想要的工作、生活状态,所以,我现在对工作没有激情、对生活也极其懒散。本着对公司负责的态度,为了不让公司其他同事受到我消极情绪 * ,也为了不让公司因为我出现业务上的纰漏等,我郑重向公司提出辞职,望公司给予批准! 祝公司稳步发展,祝公司的领导和同事们前程似锦、鹏程万里!

【优质】向政府写申请书范文-优秀word范文 (3页)

本文部分内容来自网络整理所得,本司不为其真实性负责,如有异议或侵权请及时联系,本司将立即予以删除! == 本文为word格式,下载后可方便编辑修改文字! == 向政府写申请书范文 向政府写申请书范文:企业向政府申请书范文 ******建设局: 为了更好的贯彻落实国家对资源综合利用的指导思想,促进合理的节约资源,提高资源利用率,保护环境实现经济社会的可持续发展的战略方针。 ************有限责任公司顺应形势发展,准备在******投资建设一条具有轻质、阻燃、保温、抗震性强并具有可持续发展的轻集料小型空心砌块建筑材 料生产线。 此项目的投资建设能达到节约能源、保护土地、变废为宝及综合治理环境 污染的目的。 投资建设此项目我公司具有以下优势: 一、轻集料小型空心砌块是以矿渣、炉渣、粉煤灰加有石硝为骨料,以水泥为胶结料,被广泛使用于工业与民用建筑的非承重砌块、承重砌块、保温块。 是一种节能、节土、利废的可持续发展的建筑材料。 该产品生产工艺无二次污染产生,市场前景广阔变废为宝,造福后代并具 有极高的社会效益和环境效益。 而我公司经营煤矿及煤炭销售多年,常年与矿渣、粉煤灰、水泥等物接触。 二、我公司为******热力公司供运供热用煤已有多年,合作非常融洽。

随着******城市建设规模的不断扩大,******热力公司现在每年冬季供热用煤需要4万多吨,为了保证冬季的正常供暖,秋季储存煤就非常关键,但是热力公司的场地有限,无法大量储存煤,加之供热产生的炉渣占地面积也很大。 为此双方约定由我公司申请30亩土地,其中一半无偿作为热力公司储煤场地,一半用于我公司建设轻集料小型空心砌块生产线使用,同时供热产生的炉渣及时运送到本厂作为生产原料。 充分体现了双方互利互惠的原则。 综上所述,建设轻集料小型空心砌块生产线,即符合国家产业政策,同时为确保******冬季正常供暖,热力公司秋季储煤的问题也得到了解决。 因此,恳请******建设局审批30亩土地作为************有限责任公司建设轻集料小型空心砌块生产线和******热力公司储煤场地为盼。 ************有限责任公司 20**年月日 向政府写申请书范文:向政府申请资金请示范文 县政府: XX镇政府办公楼建于X年X月,迄今XX年,由于该楼建筑时间长,加之建筑质量不好等原因,部分房间的墙体出现裂缝,虽小有修缮但仍存在屋顶掉块、墙围脱落等现象,该楼已存在安全隐患,不适宜继续办公,必须进行修缮。 经多方论证,修缮费用预算为XX万元,因镇政府资金短缺,特向县政府申请修缮办公楼经费,我们一定加强对招投标和工程质量的管理,指派专人负责办公楼修缮事宜,做到专款专用,严格质量、严格纪律,请予以支持为盼。 当否,请批示。 附:XX镇政府办公楼修缮预算开支一览表。 X县X镇人民政府

(H2N(C2H4)2NH2)[V4O10]ic951237c

Hydrothermal Syntheses and Structural Characterization of Layered Vanadium Oxides Incorporating Organic Cations:r-, -(H3N(CH2)2NH3)[V4O10]and r-, -(H2N(C2H4)2NH2)[V4O10] Yiping Zhang,?,?Robert C.Haushalter,*,?and Abraham Clearfield*,? NEC Research Institute,4Independence Way,Princeton,New Jersey08540,and Department of Chemistry,Texas A&M University,College Station,Texas77843 Recei V ed September26,1995X Four new layered mixed-valence vanadium oxides,which contain interlamellar organic cations,R-(H3N(CH2)2- NH3)[V4O10](1a), -(H3N(CH2)2NH3)[V4O10](1b),R-(H2N(C2H4)2NH2)[V4O10](2a),and -(H2N(C2H4)2NH2)- [V4O10](2b),have been prepared under hydrothermal conditions and their single-crystal structures determined: 1a,triclinic,space group P1h,a)6.602(2)?,b)7.638(2)?,c)5.984(2)?,R)109.55(3)°, )104.749- (2)°,γ)82.31(3)°,Z)1;1b,triclinic,P1h,a)6.387(1)?,b)7.456(2)?,c)6.244(2)?,R)99.89(2)°, )102.91(2)°,γ)78.74(2)°,Z)1;2a,triclinic,P1h,a)6.3958(5)?,b)8.182(1)?,c)6.3715(7)?,R )105.913(9)°, )104.030(8)°,γ)94.495(8)°,Z)1;2b,monoclinic,space group P21/n,a)9.360(2)?,b )6.425(3)?,c)10.391(2)?, )105.83(1)°,Z)2.All four of the compounds contain mixed-valence V5+/V4+vanadium oxide layers constructed from V5+O4tetrahedra and pairs of edge-sharing V4+O5square pyramids with protonated organic amines occupying the interlayer space. Introduction The contemporary interest in vanadium oxide bronzes reflects not only their interesting electronic and magnetic properties1 but also their complex structural chemistry,associated with the ability of vanadium to adopt a variety of coordination geometries in various oxidation states.In addition to the conventional alkali-metal bronzes A x V2O5,2a class of organic-based vanadium bronzes are also known.While most of the alkali-metal bronzes have been prepared at high temperatures,the organic-based vanadium bronzes are prepared at room temperature or slightly higher via intercalation reactions with vanadium pentoxide xerogels,V2O5?n H2O.The V2O5?n H2O host possesses a porous layered structure and is capable of intercalating a variety of neutral and charged guest species such as alkali-metal ions,3 alkylamines,4alcohols,5pyridine,6benzidine,7etc.The insertion of amines or metal complexes into V2O5hosts has also been reported.8The resulting intercalation compounds usually retain the lamellar structure with the guest species and water molecules occupying the interlayer regions.Partial reduction of V5+to V4+of the oxide layers has been observed to accompany the intercalation reactions with organic amines.In the cases of aniline9and thiophene,10the reduction of the vanadium oxide host,and the simultaneous oxidative polymerization of the guest molecules in the interlayer regions,have been observed.These intercalation compounds with reduced vanadium sites constitute an interesting class of organic-inorganic composite materials that can be viewed as molecular or polymer vanadium bronzes by analogy to alkali-metal bronzes.2However,the structural information about these intercalation compounds is very limited due to their amorphous or semicrystalline nature and lack of high-quality single crystals. Hydrothermal techniques,in combination with organic tem-plates,have been recently demonstrated to be well suited for the synthesis and crystal growth of reduced oxomolybdenum and oxovanadium phosphates and vanadium phosphonates.A series of novel organically templated molybdenum and vana-dium phosphates and vanadium phosphonates with molecular, two-dimensional layered,and three-dimensional open-frame-work structures have been prepared under hydrothermal condi-tions.11In contrast,hydrothermal synthesis of vanadium oxides using organic templates remains relatively unexplored.12While there are many examples of alkali-metal vanadium oxide bronzes with three-dimensional or two-dimensional structures in which the alkali metals occupy the channels or the interlayer regions, analogous organically templated vanadium oxides with3-D open *To whom all correspondence should be addressed. ?Texas A&M University. ?NEC Research Institute. X Abstract published in Ad V ance ACS Abstracts,August1,1996. (1)Murphy,D.W.;Christian,P.A.Science1979,205,651. (2)Hagenmuller,P.In Non-Stoichiometric Compounds,Tungsten Bronzes, Vanadium Bronzes and Related compounds;Bevan,D.J.,Hagen-muller,P.,Eds.;Pergamon Press:Oxford,U.K.,1973;Vol.1. (3)Lemordant,D.;Bouhaouss,A.;Aldebert,P.;Baffier,N.Mater.Res. Bull.1986,21,273. (4)Paul-Boucour,V.;Aldebert,P.Mater.Res.Bull.1983,18,1247. (5)Aldebert,P.;Baffier,N.;Legendre,J.-J.;Livage,J.Re V.Chim.Miner. 1982,19,485.Aldebert,P.;Baffier,N.;Gharbi,N.;Livage,J.Mater. Res.Bull.1981,16,949.Lemordant,D.;Bouhaouss,A.;Aldebert, P.;Baffier,N.J.Chim.Phys.Phys.-Chim.Biol.1986,83,105. (6)Ruiz-Hitzky,E.;Casal,B.J.Chem.Soc.,Faraday Trans.11986,82, 1597. (7)Hasbah,H.;Tinet,D.;Crespin,M.M.;Erre,R.;Setton,R.;Van Damme,H.J.Chem.Soc.,https://www.wendangku.net/doc/fb5115987.html,mun.1985,935. (8)Kanatzidis,M.;Marks,T.J.Inorg.Chem.1987,26,783and references therein. (9)Kanatzidis,M.;Wu,C.-G.J.Am.Chem.Soc.1989,111,4139. (10)Kanatzidis,M.;Wu,C.-G.;Marcy,H.O.;DeGroot,D.C.;Kannewurf, C.R.Chem.Mater.1990,2,222. (11)Haushalter,R.C.;Mundi,L.A.Chem.Mater.1992,4,31.Soghomo- nian,V.;Chen,Q.;Haushalter,R.C.;Zubieta,J.;O’Connor,C.J. Science1993,259,1596.Soghomonian,V.;Chen,Q.;Haushalter,R. C.;Zubieta,J.Angew.Chem.,Int.Ed.Engl.1993,32,610.Soghomo- nian,V.;Chen,Q.;Haushalter,R.C.;Zubieta,J.Chem.Mater.1993, 5,1690.Soghomonian,V.;Chen,Q.;Haushalter,R.C.;Zubieta,J., Chem.Mater.1993,5,1595.Soghomonian,V.;Haushalter,R.C.; Chen,Q.;Zubieta,J.Inorg.Chem.1994,33,1700.Zhang,Y.; Clearfield,A.;Haushalter,R.C.J.Solid State Chem.1995,117,157. Zhang,Y.;Clearfield,A.;Haushalter,R.C.Chem.Mater.1995,7, 1221. (12)Huan,G.-H.;Johnson,J.W.;Jacobson,A.J.;Merola,J.S.J.Solid State Chem.1991,91,385.Duan,C.-Y.;Tian,Y.-P.;Lu,Z.-L.;You, X.-Z.;Huang,X.-Y.Inorg.Chem.1995,34,1. 4950Inorg.Chem.1996,35,4950-4956 S0020-1669(95)01237-7CCC:$12.00?1996American Chemical Society

辞职申请书范文大全500字

辞职申请书范文大全500字 辞职申请书500字 辞职一般是提前30天向上级或公司递交辞职,无需公司批准,30天之后您就能顺利辞职了,以下是为大家搜集的范文,欢迎阅读! 尊敬的公司领导: 由于工作调动,现正式向公司提出调离原工作岗位。 舍不得,舍不得这里的人,舍不得自己曾经的付出。每一次出差、每一次报价、每一次谈判、每一次争吵,在飞机上、在吉普车上、在会议室里、在工地上,所有这一切,都充斥着我的记忆,那么清晰,就像是在昨天。但时间的指针总是忠诚地一步一步往前走,昨天终究会结束。 在公司四年半的时间里,我收获了很多,除了朋友和知识,更 重要的是,我到了成长的快乐。感谢命运,让我在最青春的年华里遇到了装备公司;感谢公司领导,你们的关注和欣赏让我一直充满自信,你们的指点和教诲让我在成长的路上少走了很多弯路;感谢公司的同事,和你们的沟通,轻松愉悦;感谢我自己,能够一直保持着一份纯净,真诚地付出,真诚地享受每一次收获。

鉴于目前的身体及生活状态,自认为不能够为公司创造更大的价值,现向公司提出辞职。 虽然我不能在这里继续“战斗”下去,但真心的希望,xx公司能够梦想成真,在世界的舞台上舞出属于自己的精彩。 此致 敬礼! 辞职人: 20xx年xx月xx日 尊敬的x总: 您好! 转眼间,我到公司已有X年了,这X年的工作时间里,虽然我的工作并不是尽善尽美,但在公司同事们的帮助,尤其是您的信任与教导下,我也努力的去完成每一项您布置给我的工作,都用了自己的

热情努力去对待。凭心而论,我开始对基础工程毫无了解,但在您这里我基本了解了基础工程,使我学到了很多东西,特别是一些做人的道理和对生活的理解。在这里,我真诚的对袁总说一声:谢谢您了! 但犹豫再三,经过了长时间的考虑,我还是写了这封辞职申请书。 加入公司以来,您对我的信任、教导与严格要求,令我非常感动,也成为激励我努力工作的动力。在您及同事们的热心指导与悉心帮助下,我在工程技术和管理能力方面都有了一定的提高。我常想,自己应该用一颗感恩的心,去回报您及公司对我的栽培,真的想用自己的努力去做好您交给的每一份工作任务,但自己的能力真的很有限,有很多地方没有做得能让您满意,所以对过去工作中失误与不足的地方,我真诚的对您说声抱歉,请您原谅! 经过这段时间的思考,我觉得我可能技术能力方面有所不足, 也缺少工作的积极性和脚踏实地的工作精神,没能很好的适应这个工作,所以一直没有把工作做到令您满意的程度。这是我在以后的人生中需要注意的地方,也是袁总经常教导我的地方,我一定会铭记于心! 再一次真诚地感谢您及公司全体同事对我的关爱与帮助!

Geological and isotopic evidence for magmatic-hydrothermal

ARTICLE Geological and isotopic evidence for magmatic-hydrothermal origin of the Ag –Pb –Zn deposits in the Lengshuikeng District,east-central China Changming Wang &Da Zhang &Ganguo Wu & M.Santosh &Jing Zhang &Yigan Xu &Yaoyao Zhang Received:7August 2012/Accepted:27March 2014/Published online:8April 2014#Springer-Verlag Berlin Heidelberg 2014 Abstract The Lengshuikeng ore district in east-central China has an ore reserve of ~43Mt with an average grade of 204.53g/t Ag and 4.63%Pb+Zn.Based on contrasting geological characteristics,the mineralization in the Lengshuikeng ore district can be divided into porphyry-hosted and stratabound types.The porphyry-hosted minerali-zation is distributed in and around the Lengshuikeng granite porphyry and shows a distinct alteration zoning including minor chloritization and sericitization in the proximal zone;sericitization,silicification,and carbonatization in the periph-eral zone;and sericitization and carbonatization in the distal zone.The stratabound mineralization occurs in volcano-sedimentary rocks at ~100–400m depth without obvious zoning of alterations and ore minerals.Porphyry-hosted and stratabound mineralization are both characterized by early-stage pyrite –chalcopyrite –sphalerite,middle-stage acanthite –native silver –galena –sphalerite,and late-stage pyrite –quartz –calcite.The δ34S values of pyrite,sphalerite,and galena in the ores range from ?3.8to +6.9‰with an average of +2.0‰.The C –O isotope values of siderite,calcite,and dolomite range from ?7.2to ?1.5‰with an average of ?4.4‰(V-PDB)and from +10.9to +19.5‰with an average of +14.8‰ (V-SMOW),respectively.Hydrogen,oxygen,and carbon iso-topes indicate that the hydrothermal fluids were derived main-ly from meteoric water,with addition of minor amounts of magmatic water.Geochronology employing LA –ICP –MS analyses of zircons from a quartz syenite porphyry yielded a weighted mean 206Pb/238U age of 136.3±0.8Ma considered as the emplacement age of the porphyry.Rb –Sr dating of sphalerite from the main ore stage yielded an age of 126.9±7.1Ma,marking the time of mineralization.The Lengshuikeng mineralization classifies as an epithermal Ag –Pb –Zn deposit. Keywords Stable isotope .Geochemistry .Porphyry .Stratabound .Ag –Pb –Zn .Lengshuikeng Introduction The Lengshuikeng ore district,located in the Jiangxi Province of east-central China (Fig.1a ),contains more than 50ore bodies belonging to seven deposits hosted in granite porphyry,pyroclastic,and carbonate rocks.The ore reserves in Lengshuikeng have been estimated at ~43Mt with average grades of 2.11%Pb,2.61%Zn,204.53g/t Ag,0.08g/t Au,and 0.01%Cd.The ores can be grouped into two types:(1)porphyry-hosted (Yinluling,Baojia,and Yinzhushan)and (2)stratabound (Xiabao,Yinkeng,Yinglin,and Xiaoyuan).The porphyry-hosted mineralization is distributed within and around the Lengshuikeng granite porphyry,whereas the stratabound mineralization occurs in volcano-sedimentary rocks at ~100–400m depth.The spatial distribution of the porphyry-hosted and stratabound ore bodies,their mineral constituents,and the zoning of alteration assemblages are markedly different from those of typical porphyry deposits. Editorial handling:T.Bissig and G.Beaudoin C.Wang (*): D.Zhang :G.Wu :M.Santosh :J.Zhang :Y .Xu :Y .Zhang State Key Laboratory of Geological Processes and Mineral Resources,China University of Geosciences,No.29,Xueyuan Road,Beijing 100083,People ’s Republic of China e-mail:wcm233@https://www.wendangku.net/doc/fb5115987.html, Y .Xu No.912Geological Surveying Team,Bureau of Geology and Mineral Exploration and Development,Yingtan 334000,China Miner Deposita (2014)49:733–749DOI 10.1007/s00126-014-0521-8

简短辞职申请书范文大全

简短辞职申请书范文大全 想必每一位在职场混迹多年的职场人士都应曾经写过辞职信之类的。在现在这个发展速度如此之快的社会,跳槽也就成了常见现象。而离职前的辞职信是必写的。下面就是小编给大家带来的简短辞职申请书范文大全,希望大家喜欢! 尊敬的xx: 我自xx年来到公司,工作中得到公司和您的培养,个人得到了很大的成长,公司的文化和环境也令我工作得非常开心。 现由于个人原因,我不得不提出辞职,希望能于x年x月x日正式离职,请公司批准我的这份辞职书。并请公司在x月x日前安排好人员接替我的工作,我将尽心交接。 再次对您x年来的培养和指导表示衷心的感谢。 最后祝您及公司的所有同事一切顺利! 此致 敬礼 辞职人:xxx 20xx年x月x日 尊敬的X经理: 您好! 感谢公司在我入职以来的培养关心和照顾,从X年X月份来到[公司]至今,我学到了很多东西,今后无论走向哪里,从事什么,这段经历都是一笔宝贵的财富,我为在彩卡的这段工作经历而自豪。 而今,由于个人原因提出辞职,望领导批准。 辞职人: 20xx年x月x日

公司人事部: 我因为要去美国留学,故需辞去现在的工作,请上级领导批准。 公司的企业文化感化了我,我对公司是深有感情的。我留学归来之后,仍愿意回公司就职。 感谢公司领导和同事在工作中对我的关心和支持,并祝公司兴隆。 辞职人:xxx 20xx年x月x日 尊敬的公司领导: 在递交这份辞呈时,我的心情十分沉重。现在由于我的一些个人原因的影响,无法为公司做出相应的贡献。因此请求允许离开。 当前公司正处于快速发展的阶段,同事都是斗志昂扬,壮志满怀,而我在这时候却因个人原因无法为公司分忧,实在是深感歉意。 我希望公司领导在百忙之中抽出时间受理我的离职事项。 感谢诸位在我在公司期间给予我的信任和支持,并祝所有同事和朋友们在工作和活动中取得更大的成绩。 辞职人: 20xx年x月x日 尊敬的xx: 自xx年入职以来,我一直很喜欢这份工作,但因某些个人原因,我要重新确定自己未来的方向,最终选择了开始新的工作。 希望公司能早日找到合适人手开接替我的工作并希望能于今年5月底前正式辞职。如能给予我支配更多的时间来找工作我将感激不尽,希望公司理解!在我提交这份辞呈时,在未离开岗位之前,我一定会尽自己的职责,做好应该做的事。 最后,衷心的说:“对不起”与“谢谢”! 祝愿公司开创更美好的未来!

- Hydrothermal Synthesis and Characterization of Single-Molecular-Layer MoS2 and MoSe2

- (H2N(C2H4)2NH2)[V4O10]ic951237c

- defects in ZnO nanorods prepared by a hydrothermal method

- Hydrothermalconversionoflignin Areview 木质素热化学转化综述

- Hydrothermal synthesis of single-crystal CeCO3OH and their thermal conversion to CeO2

- Synthesis and characterization of antimony-doped tin oxide (ATO) nanoparticles by a new hydrothermal

- fluid inclusions

- lecture-hydrothermal reaction

- CrystEngComm, 2010, 12, 260–269

- 梅森研究员1讲解

- Lithium isotopic systematics of hydrothermal vent fluids at the Main Endeavour Field

- Composition and evolution of ore fluids in a magmatic-hydrothermal skarn

- Water – The Universal Solvent - ednetnsca:水–万能溶剂ednetnsca

- A review on the formation of titania nanotube photocatalysts by hydrothermal

- Geological and isotopic evidence for magmatic-hydrothermal

- Synthesis_of_zinc_oxide_nanotetrapods_by_a_novel_fast_microemulsion-based_hydrothermal_method

- 第三章_晶体生长1

- Hydrothermal synthesis and photocatalytic properties of layered La2Ti2O7 nanosheets